Heat-insulating bituminous mixture for roads and production method thereof

A technology for asphalt mixture and road use, applied in the field of asphalt mixture, can solve the problems of reducing the service life of the road surface, accelerating the aging of asphalt, and decreasing the cohesiveness, etc., and achieves the effect of improving the service life and hindering the transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Raw material selection: based on the total volume of the mixture, limestone aggregates account for 37%; porous basalt aggregates with a particle size of 9.5mm account for 14%, porous basalt aggregates with a particle size of 4.75mm account for 19%, and fly ash drift beads with a particle size of 0.15mm Accounting for 5%, fly ash bleaching beads with a particle size of 0.075mm accounted for 8%, fly ash bleaching beads with a particle size of less than 0.075mm accounted for 4%, limestone powder: 3%, and SBS modified petroleum asphalt: 10%.

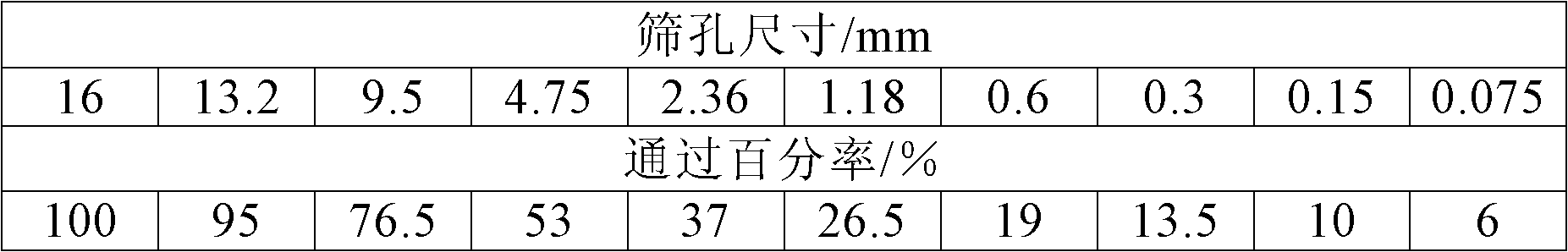

[0021] Limestone aggregate: Limestone aggregate produced in Jingyang, Shaanxi, with a density of 2.648g cm -3 , the adhesion to asphalt is grade 4, the crushing value is 8.0%, the particle size is 0.075mm~13.2mm, continuous gradation;

[0022] Porous basalt aggregate: Porous basalt aggregate produced in Sichuan, with a density of 2.576g cm -3 , the porosity is 2.2%, the adhesion level to asphalt is 4, the crushing value is 15.0%, the...

Embodiment 2~5

[0031] The heat-insulating asphalt mixtures of Examples 2-5 were produced according to the method described in Example 1, and the raw materials and their volume ratios are shown in Table 2.

[0032] Example No.

9.5mm porous basalt aggregate

4.75mm Porous Basalt Aggregate

0.15mm fly ash floating beads

0.075mm fly ash floating beads

limestone ore powder

Less than 0.075mm fly ash floating beads

SBS modified petroleum asphalt

limestone aggregate

Example 2

13

18

4

5

1

2

8

49

Example 3

14

19

5

7

2

6

9

38

Example 4

15

20

6

9

3

6

10

31

Example 5

16

21

7

9

4

6

10

27

[0033]

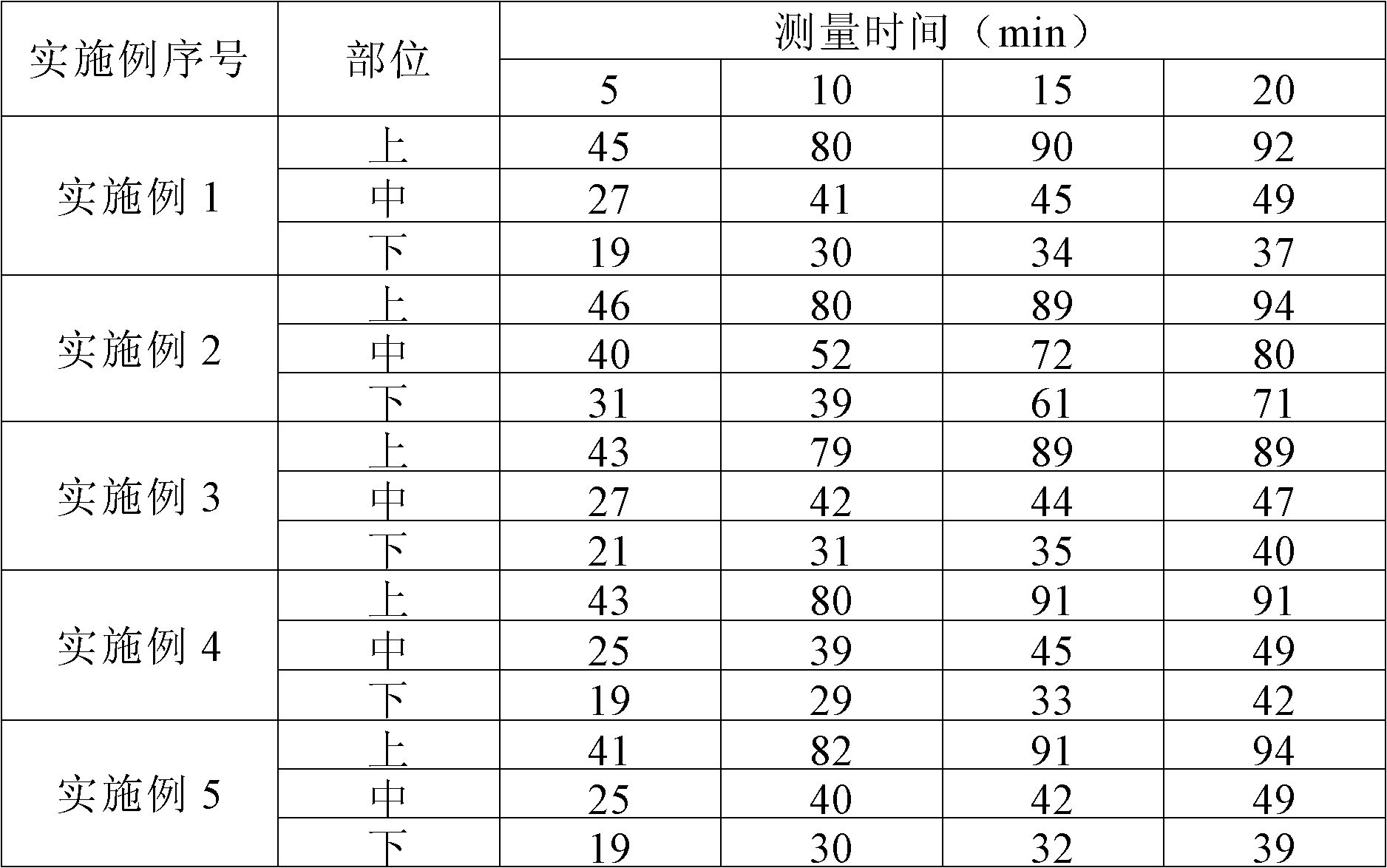

[0034] Test example:

[0035] The road heat-insulating asphalt mixture specimens formed in Examples 1 to 5 were erected on the platform and cooled a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com