Preparing method and application of heat-insulation vibration-restraining material

A technology of foam materials and foam pads, which is applied in the field of preparation of heat insulation and vibration suppression materials, can solve problems such as limited noise reduction and vibration reduction effects, high density of noise reduction and vibration reduction materials, and reduced carrying capacity of ship aerospace equipment, achieving additional The effect of small mass, wide vibration damping temperature range, and low substrate treatment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The above-mentioned preparation method of heat insulation and vibration suppression material includes:

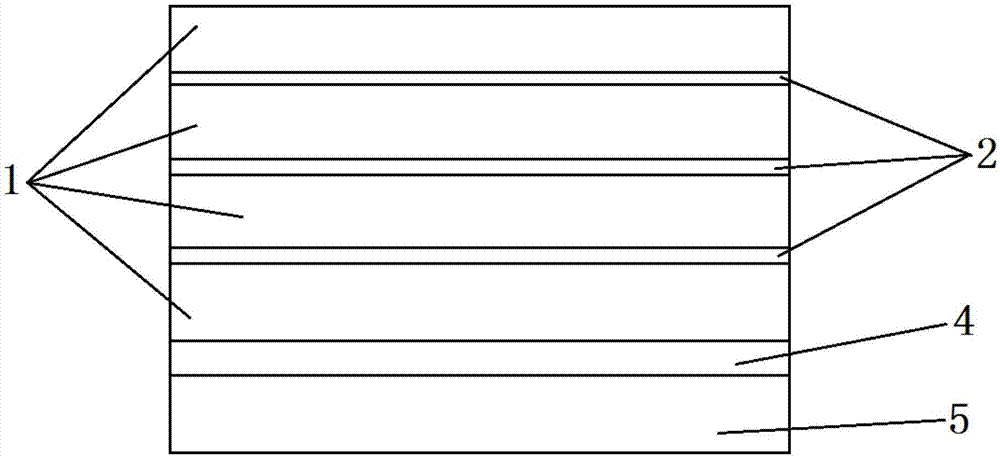

[0054] The foam material is mixed and cast to obtain the foam cushion high layer 1.

[0055] In a preferred embodiment of the present invention, in the adjacent foam cushion layer 1, the upper surface of the lower foam cushion layer 1 and / or the lower surface of the upper foam cushion layer 1 are respectively coated with damping glue, and Adjacent foam cushion high layer 1 is bonded and compacted to obtain damping layer 2, so that adjacent foam cushion high layer 1 is fixedly connected.

[0056] The preparation method of the heat insulation and vibration suppression material of the present invention is simple in process, short in preparation time, and fast in construction. Through the use of different raw materials and thicknesses, the hardness, thickness, and modulus are adjustable, and organic solvents are not used, and they are non-toxic, non-flammable and inflammable. ...

Embodiment 1

[0096] A preparation method of heat insulation and vibration suppression material, including:

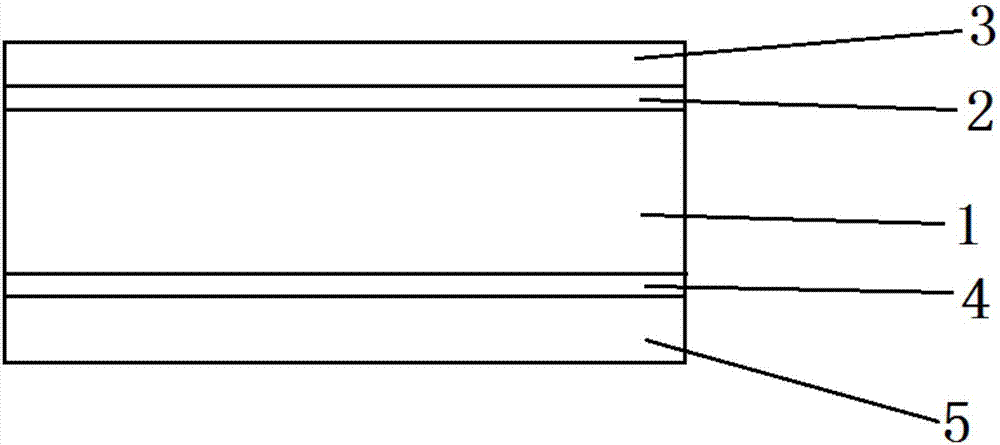

[0097] Structure like figure 1 As shown, a layer of damping glue is coated on the 80mm thick polystyrene foam cushion layer 1, and a 2mm thick butadiene rubber layer 3 (loss factor of 1.2) is laid on the damping glue. Compact for about 12h, take it out, the thickness of the obtained damping adhesive layer is 2mm, inspect and package.

Embodiment 2

[0099] A preparation method of heat insulation and vibration suppression material, including:

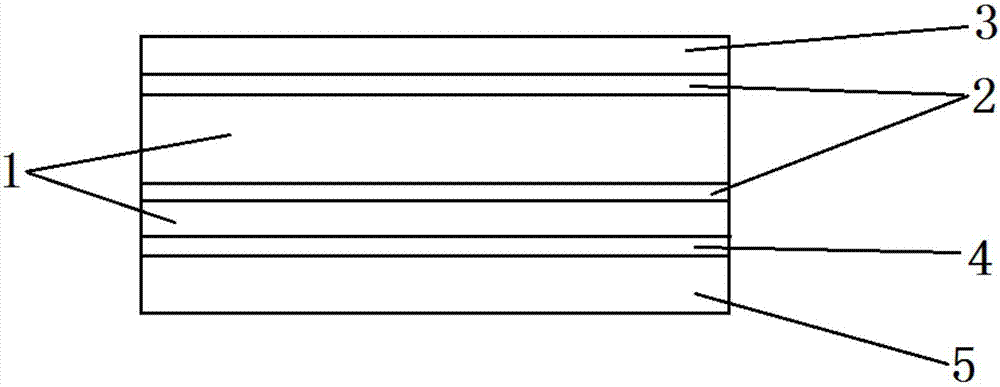

[0100] Structure like figure 2 As shown, take 1 layer of 2mm thick polyethylene foam cushion high layer 1 and a layer of 20mm thick polyurethane foam cushion high layer 1, and coat a layer of damping glue on the 2mm thick polyethylene foam cushion high layer 1, and lay on the damping glue A 20mm thick polyurethane foam cushion top layer 1, and then a layer of damping glue on the 20mm thick polyurethane foam cushion top layer 1, and a 30mm thick nitrile rubber layer 3 (loss factor 0.4) on the damping glue. At room temperature, glue and compact for about 12 hours, take it out, the damping layer 2 between the 2mm thick polyethylene foam cushion high layer 1 and the 20mm thick polyurethane foam cushion high layer 1 is 0.1mm thick, and the 20mm thick polyurethane foam cushion high layer obtained The thickness of the damping layer 2 between 1 and the nitrile rubber layer 3 is 1mm for inspec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com