Fluorocarbon matte finishing paint curable at normal temperature and preparation method thereof

A technology of room temperature curing and finishing paint, which is applied in coatings, anti-corrosion coatings, etc. It can solve the problems of low non-stick performance and dirt cleaning function, affecting the color or pattern of the substrate, and low water vapor permeability. , to achieve the effect of simple protective construction method, dense paint film and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

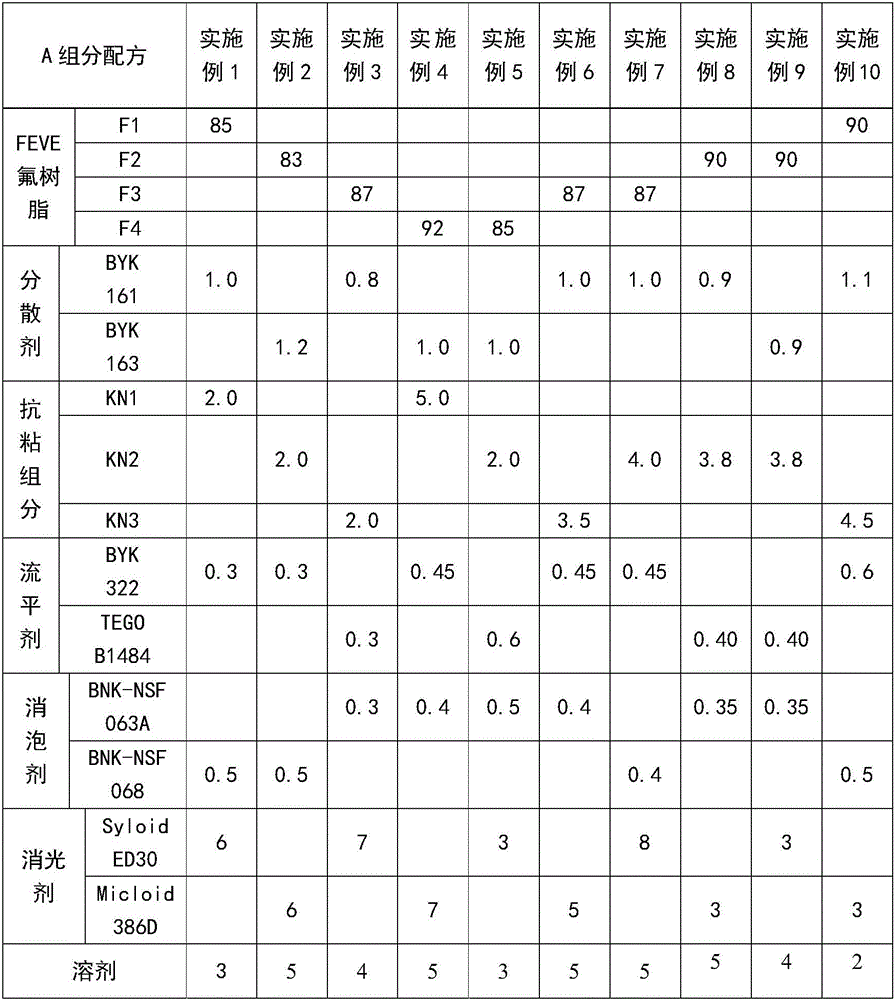

[0047] The present invention is further illustrated below in conjunction with specific examples, but these examples are only for explaining the present invention, rather than limiting the scope of the present invention.

[0048] The FEVE fluororesin (hereinafter represented by F1-F4) in the embodiment is all self-made, and the resin composition is as follows:

[0049] F1, self-made, is made by copolymerization of chlorotrifluoroethylene, ethyl vinyl ether, Veova9 and hydroxyethyl acrylate, the fluorine content is 18%, the hydroxyl value is 41mgKOH / g, and the Tg is 55°C.

[0050] F2, self-made, is made by copolymerization of tetrafluoroethylene, vinyl acetate, Veova10, ethylene glycol allyl ether and crotonic acid. The fluorine content is 29.8%, the hydroxyl value is 30mgKOH / g, and the Tg is 70°C.

[0051] F3, self-made, copolymerized from chlorotrifluoroethylene, vinyl acetate, Veova9, Veova10, 4-hydroxybutyl vinyl ether, undecylenic acid, fluorine content 25%, hydroxyl value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com