Nuclear shell type long-acting antibacterial emulsion and preparation method thereof

An antibacterial emulsion, core-shell type technology is applied in the field of guanidine salt-containing emulsion and its preparation, which can solve the problems of pollution and unsustainable antibacterial effect, achieve lower film-forming temperature, simple preparation process and lower storage stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

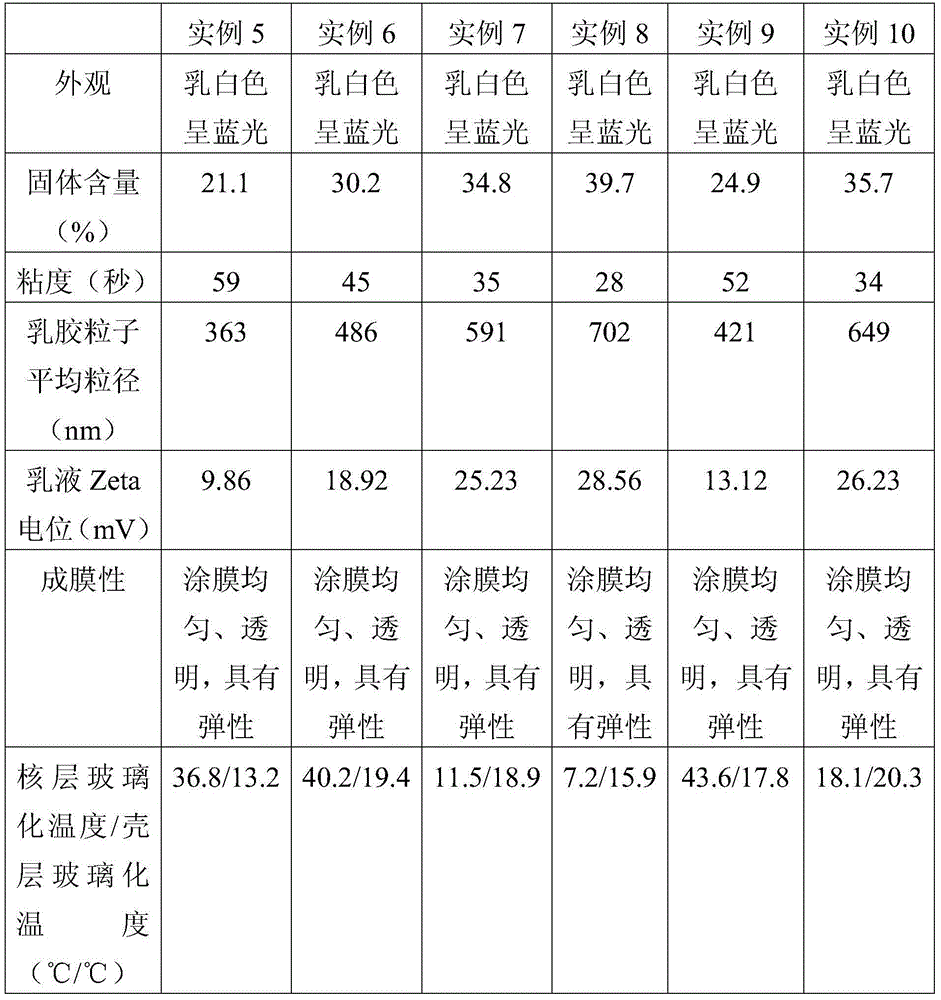

Examples

Embodiment 1

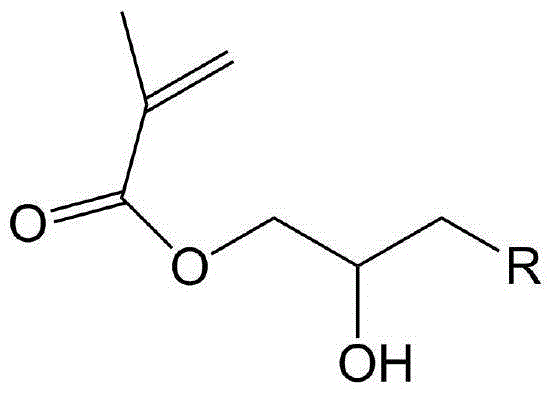

[0033] Preparation of polyhexamethyleneguanidine hydrochloride macromonomer (GPHMG):

[0034] Taking by weighing molecular weight is that polyhexamethylene guanidine hydrochloride 40g of 500 is dissolved in 60g deionized water and is made into the guanidine solution that mass fraction is 40%; Nitrogen, 11.3g GMA is slowly added dropwise in this guanidine solution, continue to Under the protection of nitrogen, stir the reaction at room temperature for 24 hours until the oil phase disappears completely, which is obtained.

Embodiment 2

[0036] Preparation of polyhexamethyleneguanidine hydrochloride macromonomer (GPHMG):

[0037] Taking by weighing molecular weight is 700 polyhexamethylene guanidine hydrochloride 30g and is dissolved in 70g distilled water water and is made into the guanidine solution that mass fraction is 30%; Logical argon, 6.7g GMA is slowly added dropwise in this guanidine solution, continue in Under the protection of argon, the reaction was stirred at room temperature for 18 hours until the oil phase disappeared completely, which was obtained.

Embodiment 3

[0039] Preparation of polyhexamethylene biguanide hydrochloride macromonomer (GPHMB):

[0040] Taking by weighing molecular weight is that 800 polyhexamethylene biguanide hydrochloride 25g is dissolved in 75g purified water and is made into the guanidine solution that mass fraction is 25%; Logical helium, 5.1g GMA is slowly added dropwise in this guanidine solution, continue in Under the protection of helium, the reaction was stirred at room temperature for 16 hours until the oil phase disappeared completely, which was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com