Energy-saving type transparent coating with functions of heat reflection and heat insulation

A transparent coating and heat reflection technology, applied in radiation-absorbing coatings, anti-fouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve problems such as heat loss, increased heating costs, and increased cooling costs to achieve heat insulation Excellent performance, good heat insulation performance, good stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

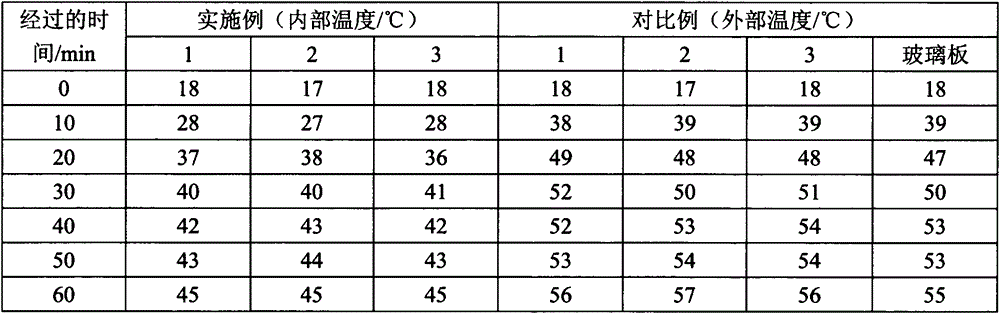

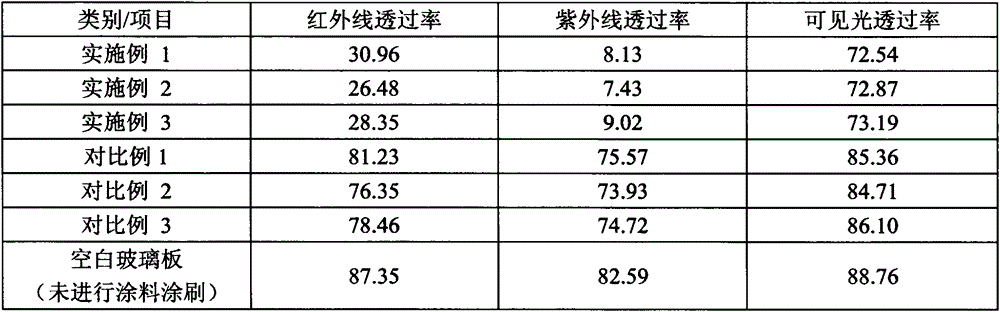

Examples

Embodiment 1

[0037] The energy-saving heat-reflecting and heat-insulating transparent coating based on thermosetting silicone acrylic resin is made according to the composition ratio in Table 1.

[0038] Table 1 The component distribution ratio of the energy-saving heat-reflecting and heat-insulating transparent coating of the thermosetting silicone acrylic resin system

[0039] Composition

Embodiment 2

[0041] The naturally drying energy-saving heat-reflecting heat-insulating transparent coating is made according to the composition ratio in Table 2.

[0042]Table 2 The component distribution ratio of the energy-saving heat-reflecting heat-insulating transparent coating of natural drying type

[0043] Composition

Embodiment 3

[0045] UV curable (UV curable) stain-resistant energy-saving heat-reflective heat-insulating transparent coating, made according to the composition ratio in Table 3.

[0046] Table 3 Component distribution ratio of energy-saving heat-reflective and heat-insulating transparent coatings with UV curability and stain resistance

[0047] Composition

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com