Quick-drying friction-resisting high-temperature-resistant primer and preparation method thereof

A friction-resistant and high-temperature-resistant technology, applied in the field of primer and its preparation, can solve the problems of operator's health hazards, reduce equipment service life, poor high-temperature resistance ability, etc., to improve physical and mechanical properties, reduce rust, and improve gloss. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

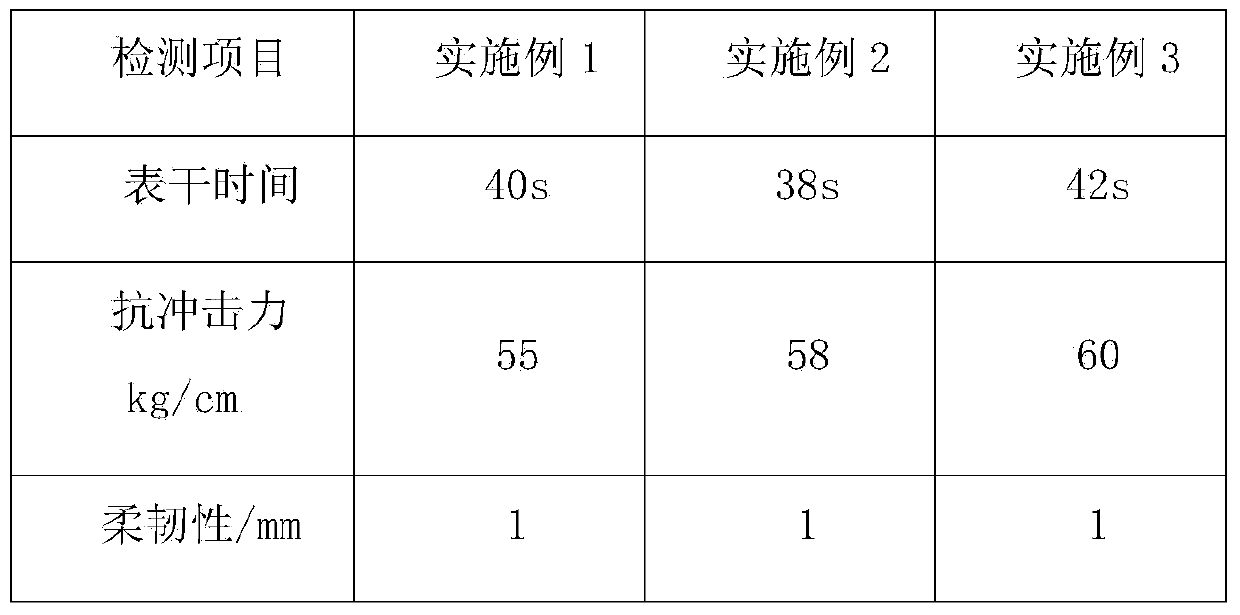

Embodiment 1

[0032] A kind of quick-drying friction-resistant, high-temperature-resistant primer provided by the present embodiment is characterized in that: the primer is made of bisphenol F type liquid epoxy resin, iron red powder, titanium dioxide, silicon micropowder, multifunctional auxiliary agent AMP-95 , graphite powder, polyethylene glycol and organic fluorine-modified acrylic resin, and its weight percent composition is: bisphenol F type liquid epoxy resin: 23%, iron red powder: 5%, titanium dioxide: 12%, silicon micropowder: 10% %, multifunctional additive AMP-95: 15%, graphite powder: 12%, polyethylene glycol: 3%, and the balance is organic fluorine-modified acrylic resin; the preparation method of the fast-drying friction-resistant, high-temperature-resistant primer Follow these steps:

[0033] Step (1): first put the bisphenol F type liquid epoxy resin and the organic fluorine-modified acrylic resin into the stirring tank for mixing, control the temperature in the stirring ta...

Embodiment 2

[0038]A kind of quick-drying friction-resistant, high-temperature-resistant primer provided by the present embodiment is characterized in that: the primer is made of bisphenol F type liquid epoxy resin, iron red powder, titanium dioxide, silicon micropowder, multifunctional auxiliary agent AMP-95 , graphite powder, polyethylene glycol and organic fluorine-modified acrylic resin, and its weight percent composition is: bisphenol F type liquid epoxy resin: 25%, iron red powder: 8%, titanium dioxide: 15%, silicon micropowder: 12% %, multifunctional additive AMP-95: 18%, graphite powder: 15%, polyethylene glycol: 8%, and the balance is organic fluorine-modified acrylic resin; the preparation method of the fast-drying friction-resistant, high-temperature-resistant primer Follow these steps:

[0039] Step (1): first put the bisphenol F type liquid epoxy resin and the organic fluorine modified acrylic resin into the stirring tank for mixing, control the temperature in the stirring tan...

Embodiment 3

[0044] A kind of quick-drying friction-resistant, high-temperature-resistant primer provided by the present embodiment is characterized in that: the primer is made of bisphenol F type liquid epoxy resin, iron red powder, titanium dioxide, silicon micropowder, multifunctional auxiliary agent AMP-95 , graphite powder, polyethylene glycol and organic fluorine-modified acrylic resin, and its weight percent composition is: bisphenol F type liquid epoxy resin: 24%, iron red powder: 7%, titanium dioxide: 13%, silicon micropowder: 11% %, multifunctional additive AMP-95: 17%, graphite powder: 13%, polyethylene glycol: 5%, and the balance is organic fluorine-modified acrylic resin; the preparation method of the fast-drying friction-resistant, high-temperature-resistant primer Follow these steps:

[0045] Step (1): first put the bisphenol F type liquid epoxy resin and the organic fluorine-modified acrylic resin into the stirring tank for mixing, control the temperature in the stirring ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com