Multifunctional composite coating of oil gas storage tank and preparation method thereof

A technology for composite coatings and oil and gas storage tanks, applied in coatings, anti-corrosion coatings, layered products, etc., can solve problems such as loss of sun protection and heat insulation functions, short service life of coating materials, and increased operating costs of enterprises. Eliminate power consumption water spray equipment and water spray cooling control process, the effect of stain resistance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the multifunctional composite coating for oil and gas storage tanks of the present invention comprises the following steps: 1. According to weight percentage, rutile type titanium dioxide 4.0~5.0, calcite powder 9.0~10.0, talcum powder 1.0~2.0, zinc borate 3.5~ 4.0, aluminum hydroxide 1.0~1.5, decabromodiphenyl ether 6.0~7.0 and other powder materials and additives melamine formaldehyde resin 2.0~4.0, BYK306 wetting and dispersing agent 0.2~0.3, 5800 leveling agent 0.3~0.5, 2400 Leveling agent 0.1-0.15, dibutyl phthalate 1.6-2.0, 10% organic silicon defoamer 0.15-0.25 mixed, high-speed wetting and dispersing and grinding to a fineness of not more than 20 μm, filtered, in the system Fully mix with polyacrylic resin 40.0-45.0 in the paint pot, filter the tank to get the bottom product; 2. According to weight percentage, cellulose acetate butyrate CAB381-0.5 resin 10.0-13.0, rutile titanium dioxide 6.0-8.0, Calcite powder 10.0~14.0, talc powder 0....

Embodiment 1

[0065] The weight percent component that polyacrylic resin coating comprises is:

[0066] 1. Polyacrylic resin 42.0

[0067] 2. Melamine formaldehyde resin 4.0

[0068] 3. Nitrocellulose 1.1

[0069] 4. Dibutyl phthalate 1.6

[0070] 5. 5800 leveling agent 0.3

[0071] 6. 2400 leveling agent 0.15

[0072] 7. BYK306 wetting and dispersing agent 0.25

[0073] 8. 10% silicone defoamer 0.2

[0074] 9. Rutile titanium dioxide 4.5

[0075] 10. Calcite powder 10.0

[0076] 11. Talc powder 1.1

[0077] 12. Decabromodiphenyl ether 6.2

[0078] 13. Zinc borate 3.6

[0079] 14. Aluminum hydroxide 1.2

[0080] 15. Static conductive agent 3297 1.8

[0081] 16. X501 solvent 22.0

[0082] The weight percent components contained in fluorocarbon resin coatings are:

[0083] 1. Fluorocarbon resin with 25% fluorine content 48.0

[0084] 2. 20% CAB381-0.5 resin 12.0

[0085] 3. BYK306 wetting and dispersing agent 1.31

[0086] 4. 10% silicone defoamer 0.34

[0087] 5. Rutile tit...

Embodiment 2

[0111] The weight percent component that polyacrylic resin coating comprises is:

[0112] 1. Polyacrylic resin 45.0

[0113] 2. Melamine formaldehyde resin 4.0

[0114] 3. Nitrocellulose 1.0

[0115] 4. Dibutyl phthalate 1.6

[0116] 5. 5800 leveling agent 0.3

[0117] 6. 2400 leveling agent 0.15

[0118] 7. BYK306 wetting and dispersing agent 0.2

[0119] 8. 10% silicone defoamer 0.15

[0120] 9. Rutile titanium dioxide 4.0

[0121] 10. Calcite powder 10.0

[0122] 11. Talc powder 1.0

[0123] 12. Decabromodiphenyl ether 6.0

[0124] 13. Zinc borate 4.0

[0125] 14. Aluminum hydroxide 1.0

[0126] 15. Static conductive agent 3297 1.6

[0127] 16. X501 solvent 20.0

[0128] The weight percent components contained in fluorocarbon resin coatings are:

[0129] 1. Fluorocarbon resin with 25% fluorine content 49.0

[0130] 2. 20% CAB381-0.5 resin 13.0

[0131] 3. BYK306 wetting and dispersing agent 1.4

[0132] 4. 10% silicone defoamer 0.3

[0133] 5. Rutile titan...

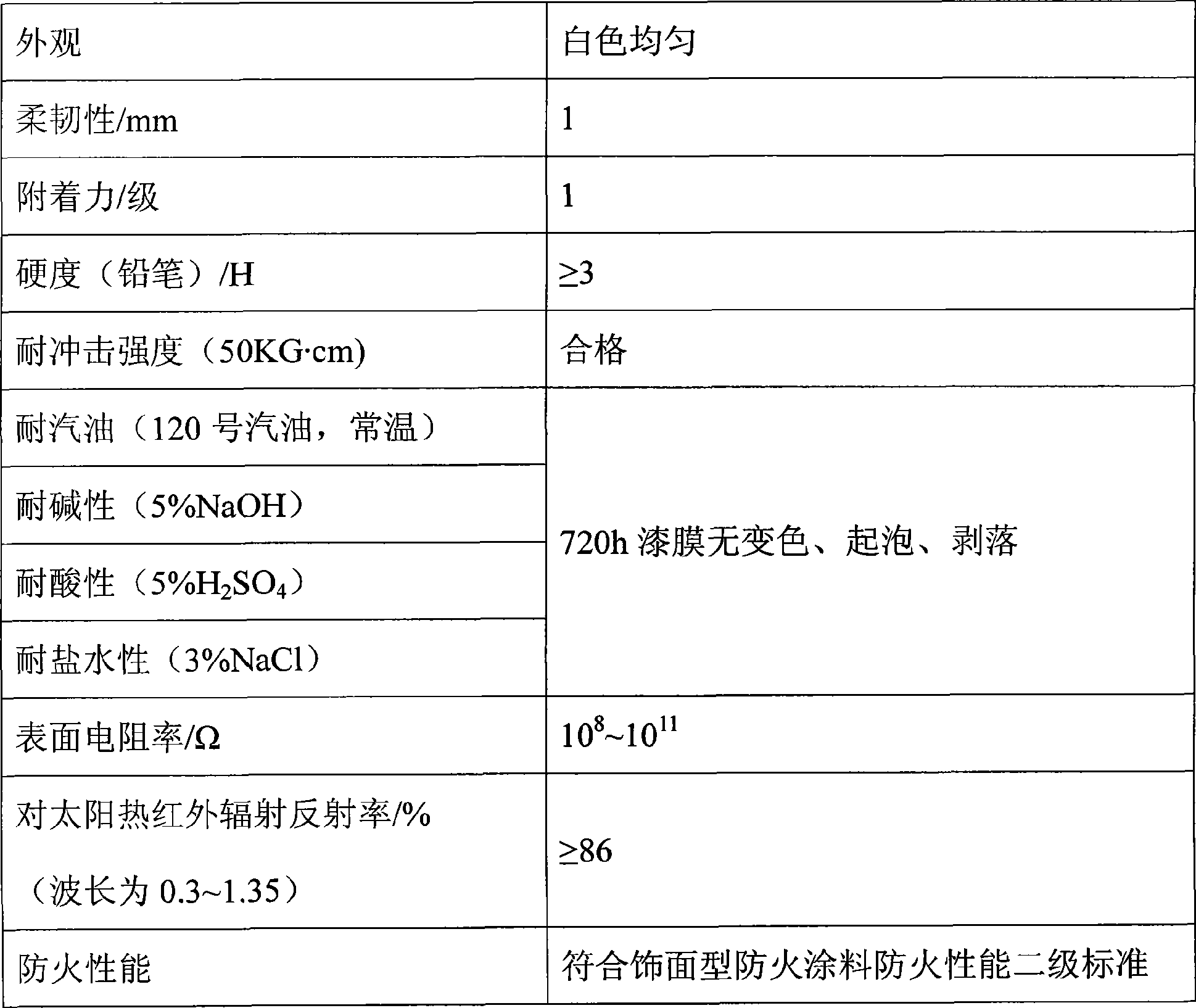

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com