Water-based primer-topcoat in one type paint

A bottom surface, water-based technology, applied in the direction of latex paint, coating, etc., can solve the problems of weather resistance, stain resistance, poor color retention, high labor intensity of workers, and the coating film is easy to bulge and form bubbles, etc., to achieve excellent adhesion , optimize the construction process and reduce the effect of labor level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

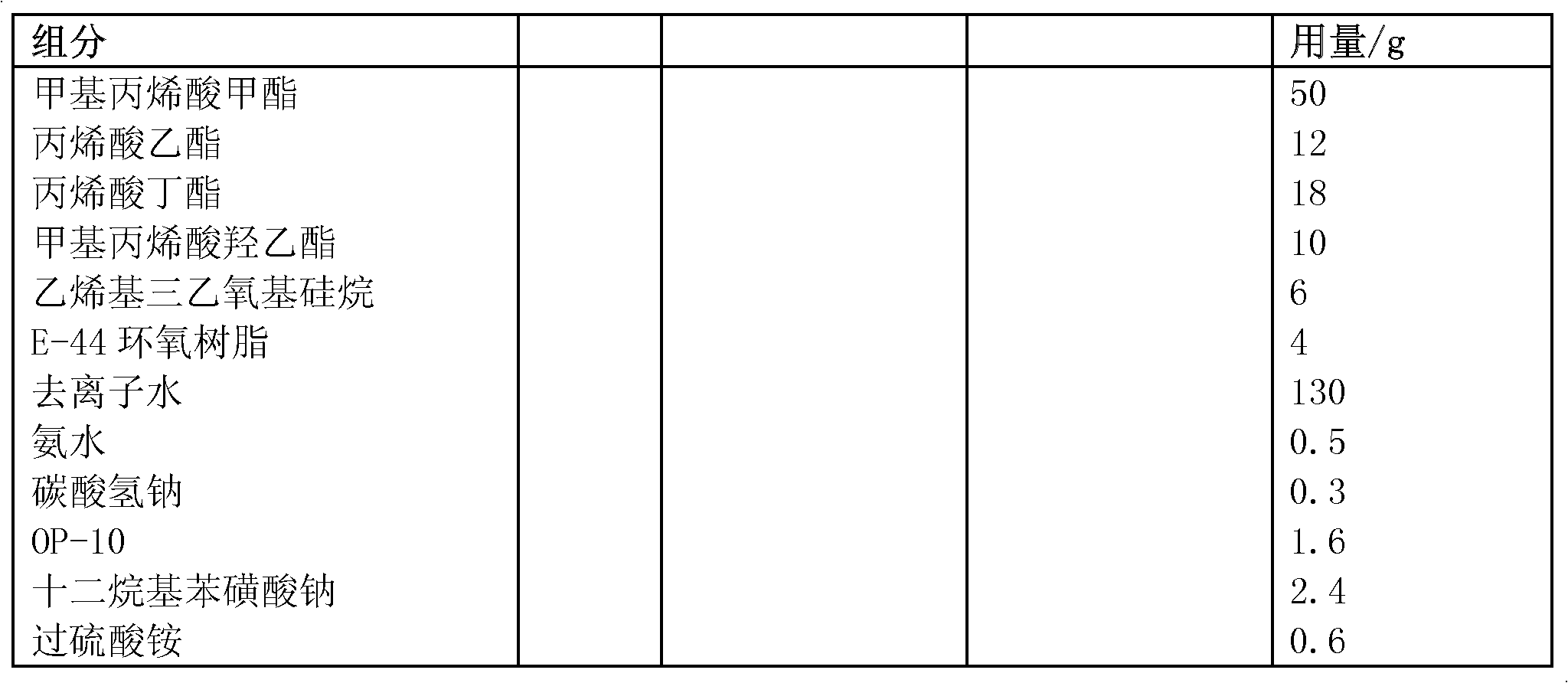

Embodiment 1

[0046] The coating formulation of the present invention is: 300.0g deionized water, 25.0g propylene glycol, 6.0g dispersant AG165, 2.0g multifunctional auxiliary agent AMP-95, 3.0g defoamer A10, 2.0g Casson preservative LXE, 2.0g Anti-mildew and anti-algae agent R-2000, 185.0g rutile titanium dioxide R-902, 50.0g high-gloss barium, 400g epoxy modified silicon acrylic emulsion, 35.0g film-forming aid alcohol ester-12, 4.0g rheology additive RM-2020, 6.0g thickener TT-935.

[0047]Add co-solvent, dispersant, multi-functional additive, 1 / 2 of the total amount of defoamer, rutile titanium dioxide and high-gloss barium in water in sequence, disperse at high speed until the fineness is acceptable, and then add epoxy modified silicone acrylic emulsion, 1 / 2 of the total amount of defoaming agent, film-forming aid, preservative, anti-mildew and anti-algae agent, rheological additive and thickener are adjusted to a suitable viscosity, and finally the finished water-based primer and surf...

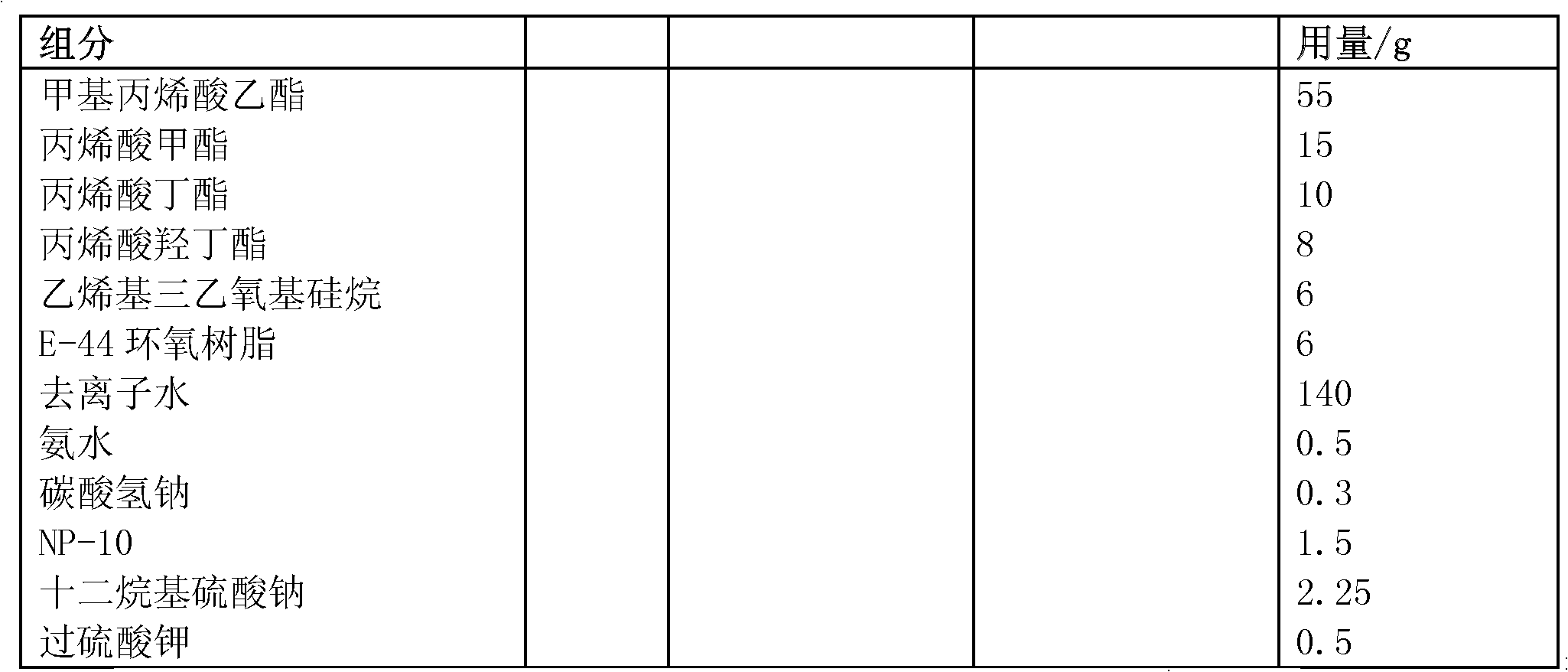

Embodiment 2

[0049] The coating formula of the present invention is: 305.0g deionized water, 25.0g ethylene glycol, 8.0g dispersant 1124, 2.5g multifunctional additive AMP-95, 3g defoamer NXZ, 1.5gBIT preservative PROXEL AQ, 3.0g Anti-mildew and anti-algae agent R-2000, 170.0g rutile titanium dioxide, 80.0g calcium carbonate, 360g epoxy modified silicone acrylic emulsion, 30.0g film-forming aid benzyl alcohol, 5.0g rheology additive RM-2020, 7.0 g Thickener TT-935. The preparation process is the same as in Example 1.

Embodiment 3

[0051] The paint formula of the present invention is: 292.0g deionized water, 25.0g propylene glycol, 6.0g dispersant CA2500, 3.0g multifunctional additive AMP-95, 4.0g defoamer NXZ, 3.0g BIT preservative PROXELAQ, 4.0g anti-mildew Anti-algae agent R-2000, 190.0g rutile titanium dioxide, 40.0g calcium carbonate, 20.0g kaolin, 420.0g epoxy modified silicon acrylic emulsion, 40.0g film-forming aid ethylene glycol butyl ether, 6.0g rheological aid Agent RM-2020, 6.0g thickener TT-935. The preparation process is the same as in Example 1.

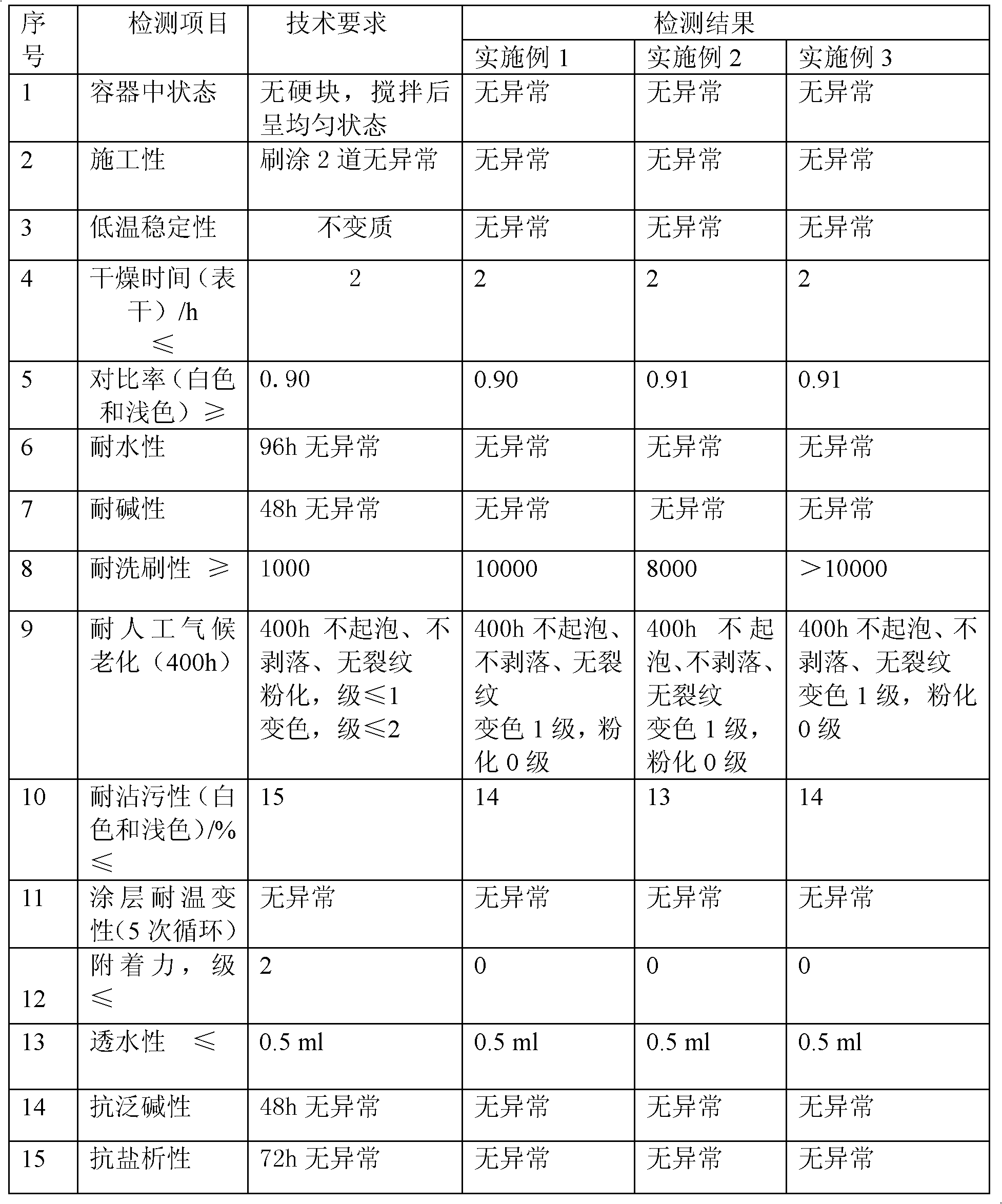

[0052] The performance of embodiment gained bottom surface all-in-one paint is as following table:

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com