Nano-alloy particles and patterning method thereof

A nano-alloy and particle technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as high cost, oxidation, and poor air stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

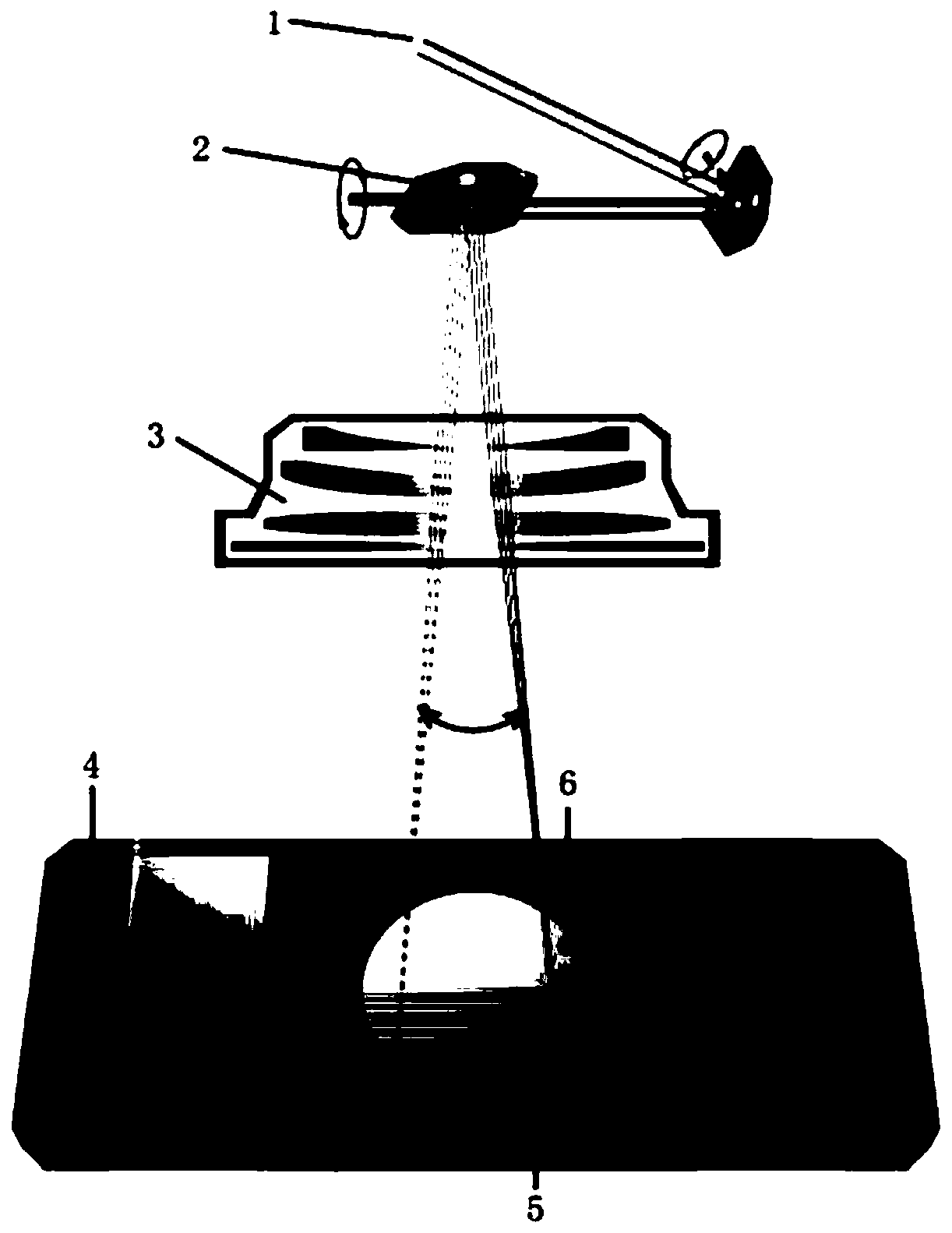

Method used

Image

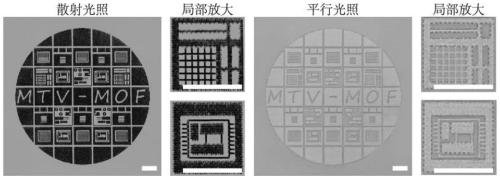

Examples

Embodiment 1

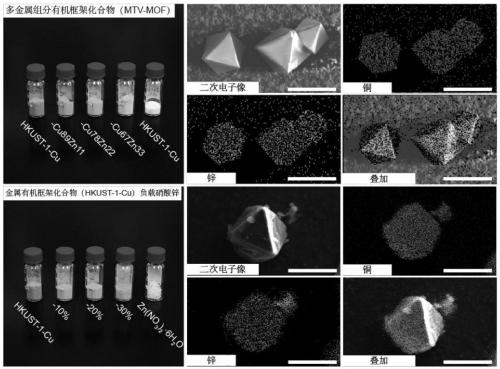

[0085] Preparation of Cu containing Cu by solvothermal method 2+ and Zn 2+ Multimetal Component Organic Framework Compound HKUST-1-CuZn Micron Crystalline Powder (Such as figure 2 shown) , use dimethylformamide to dissolve copper nitrate, zinc nitrate and trimesic acid, and heat at 85 degrees Celsius for 12 hours to obtain a blue crystal powder, which can be adjusted by changing the ratio of copper nitrate and zinc nitrate used in the synthesis. Metal ratios in HKUST-1-CuZn. After the impurities were removed by solvent washing, the solvent in the channels of HKUST-1-CuZn was removed by heating to obtain a dry HKUST-1-CuZn powder sample. X-ray powder diffraction proves that the obtained HKSUT-1-CuZn crystal powder diffraction peaks completely match their simulated diffraction peaks, scanning electron microscopy and energy dispersive X-ray analysis prove that Cu and Zn have the same distribution in the crystal, thus proving that the obtained multiple Metal-component organi...

Embodiment 2

[0090] Preparation of Cu containing Cu by solvothermal method 2+ The metal-organic framework compound HKUST-1-Cu micron crystal powder is washed with a solvent to remove impurities, and the solvent in the HKUST-1-Cu channel is removed by heating to obtain a dry HKUST-1-Cu powder sample. X-ray powder diffraction demonstrates that the obtained HKSUT-1-Cu crystal powder diffraction peaks exactly match their simulated diffraction peaks, thus demonstrating the pure phase of the obtained metal-organic framework material.

[0091] 110mg of the obtained HKUST-1-Cu powder was uniformly dispersed into 1ml dissolved with 6.5mg of Zn(NO 3 ) 2 ·6H 2 O ethanol solution, stirred at room temperature for 2 hours and then placed in room temperature for vacuum drying to obtain a Zn-loaded 2+ HKUST-1-Cu powder sample (Such as figure 2 shown) . The powder sample was prepared into a powder layer sample according to the method in Example 1 and scanned with a laser, and uniform Cu-Zn nano-a...

Embodiment 3

[0094] Prepared by solvothermal method containing Cu respectively 2+ and Zn 2+ The metal-organic framework compound HKUST-1-Cu and MOF-74-Zn micron crystal powder, after solvent washing to remove impurities, heating to remove the solvent in the channels of HKUST-1-Cu and MOF-74-Zn, to obtain dry HKUST - 1-Cu and MOF-74-Zn powder samples. X-ray powder diffraction demonstrated that the obtained HKSUT-1-Cu and MOF-74-Zn crystal powder diffraction peaks perfectly matched their simulated diffraction peaks, thus demonstrating the pure phase of the obtained MOF materials. The crystal powders of HKUST-1-Cu and MOF-74-Zn are mixed, stirred evenly and ground to obtain a metal organic framework compound mixture. The powder sample was prepared into a powder layer sample according to the method in Example 1 and scanned with a laser, and uniform Cu-Zn nano-alloy particles could be obtained on the surface of the glass sheet.

[0095] The obtained Cu-Zn nano-alloy particles were observed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com