Magnetic silicon dioxide microspheres with nuclear shell and surface anisotropic double functional groups and preparation method thereof

A silica and anisotropic technology, applied in the field of magnetic silica microspheres and their preparation, to achieve the effects of good repeatability, strong versatility and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

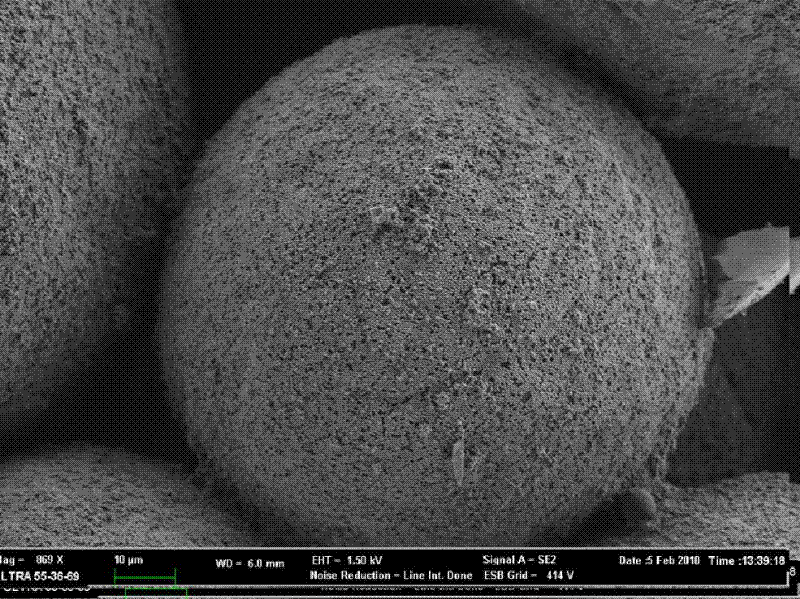

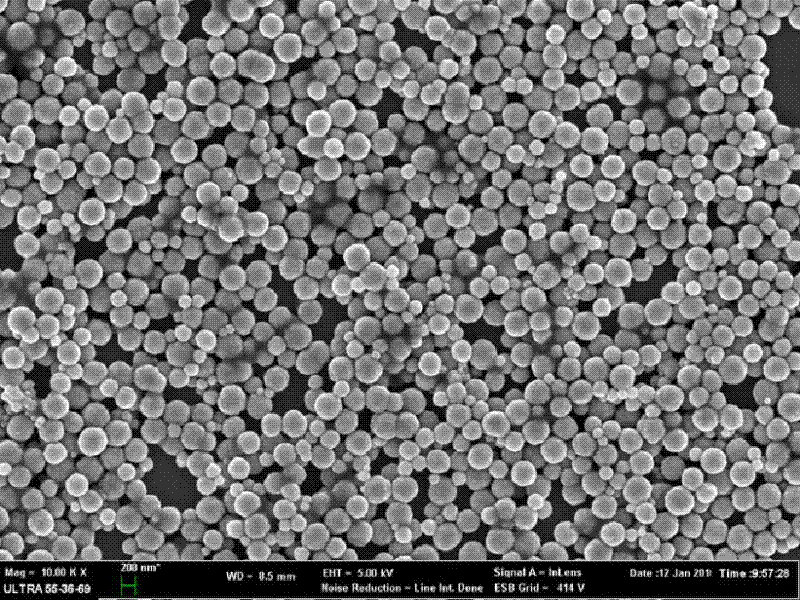

[0035] Example 1. 0.81 g FeCl 3 ·6H 2 O and 2.16 g of sodium citrate were dissolved in 30 ml of ethylene glycol respectively, and after mixing, they were moved into a stainless steel reaction kettle with a tetrafluoroethylene liner, tightened the reaction kettle, heated to 200 ° C, and reacted for 8 hours to obtain the average particle size. The 350 nm inorganic magnetic microspheres were washed with ethanol and water three times under magnetic separation. Obtain magnetic separation products of magnetic microspheres; use strong acid to activate inorganic magnetic microspheres, disperse inorganic magnetic microspheres in deionized water, use magnetic field to separate and wash, and then disperse in 1 M hydrochloric acid solution, ultrasonication for 10-40 Minutes, then use a magnet to separate the magnetic microspheres treated with strong acid, and wash with deionized water 3-5 times. Add the dispersion of magnetic microspheres activated by strong acid into the alcohol / wat...

Embodiment 2

[0039] Example 2. 0.81 g FeCl 3 ·6H 2 O and 2.16 g of sodium citrate were dissolved in 30ml of ethylene glycol respectively. After mixing, they were moved into a stainless steel reaction kettle with a tetrafluoroethylene liner, tightened the reaction kettle, heated to 200°C, and reacted for 16 hours to obtain the average particle size. The 400 nm inorganic magnetic microspheres were washed 3 times with ethanol and water respectively under magnetic separation. Obtain magnetic separation products of magnetic microspheres; use strong acid to activate inorganic magnetic microspheres, disperse inorganic magnetic microspheres in deionized water, use magnetic field to separate and wash, and then disperse in 1 M hydrochloric acid solution, ultrasonication for 10-40 Minutes, then use a magnet to separate the magnetic microspheres treated with strong acid, and wash with deionized water 3-5 times. Add the dispersion of magnetic microspheres activated by strong acid into the alcohol / w...

Embodiment 3

[0043] Example 3. 0.81 gFeCl 3 ·6H 2O and 2.16 g of sodium citrate were dissolved in 30ml of ethylene glycol respectively. After mixing, they were moved into a stainless steel reaction kettle with a tetrafluoroethylene liner, tightened the reaction kettle, heated to 200°C, and reacted for 24 hours to obtain the average particle size. Inorganic magnetic microspheres of 520 nm were washed with ethanol and water three times under magnetic separation. Obtain magnetic separation products of magnetic microspheres; use strong acid to activate inorganic magnetic microspheres, disperse inorganic magnetic microspheres in deionized water, use magnetic field to separate and wash, and then disperse in 1 M hydrochloric acid solution, ultrasonication for 10-40 Minutes, then use a magnet to separate the magnetic microspheres treated with strong acid, and wash with deionized water 3-5 times. Add the dispersion of magnetic microspheres activated by strong acid into the alcohol / water mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com