Smelting method and patterning method of nano metal particles

A technology of nano-metal particles and smelting methods, which is applied in the direction of nanotechnology, nanotechnology, metal material coating technology, etc., and can solve problems such as inability to adapt, micron or nanoscale, and complex preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

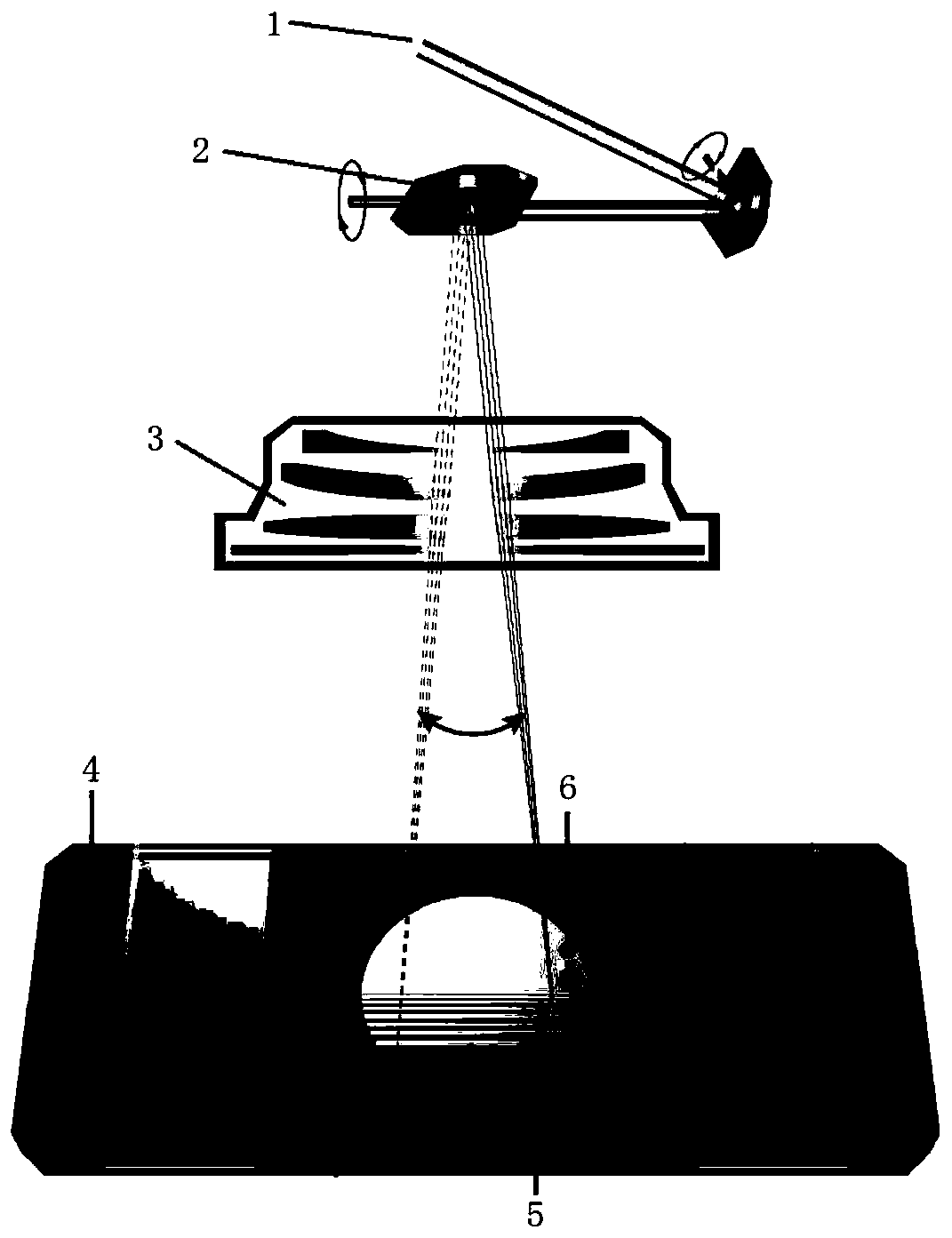

[0056] A nano metal particle smelting device: composed of a laser, a metal-organic compound 5, a vibrating mirror 2 and a concentrating mirror 3;

[0057] Laser: emit light beam 1 as a light source to provide localized efficient heating and reduction heat source; other light sources can also be used;

[0058] Metal-organic compound 5: as a metal source for smelting nano-metal particles and as a reducing agent for the reduction of metals;

[0059] Substrate 4: used to carry the metal-organic compound 5, and provide a carrier for the deposition of the prepared nano-metal particles or the pattern 6 of the nano-metal particles;

[0060] Vibrating mirror 2: It can precisely control the direction of the beam 1 to realize the precise deposition of nano-metal particles during the laser scanning process; the vibrating mirror 2 includes various automatic or manual optical lenses that can deflect the laser or other parallel beams and One or a combination of several lens groups; the vibr...

Embodiment 2

[0063] The metal organic framework compound HKUST-1 micron crystal powder containing Cu2+ was prepared by solvothermal method. After the impurities were removed by solvent washing, the solvent in the channels of HKUST-1 was removed by heating to obtain a dry HKUST-1 powder sample. X-ray powder diffraction demonstrated that the obtained HKSUT-1 crystal powder diffraction peaks perfectly matched their simulated diffraction peaks, thus demonstrating the pure phase of the obtained MOFs.

[0064] The obtained HKUST-1 powder is uniformly filled in a metal foil with a circular cavity, the thickness of the metal foil is 10 μm, and the diameter of the cavity is 16 mm, and 8 mg of HKUST-1 powder is evenly pressed with two glass sheets Between two glass sheets, both ends of the glass sheet are fixed with adhesive tape to form a sample of a sandwich structure.

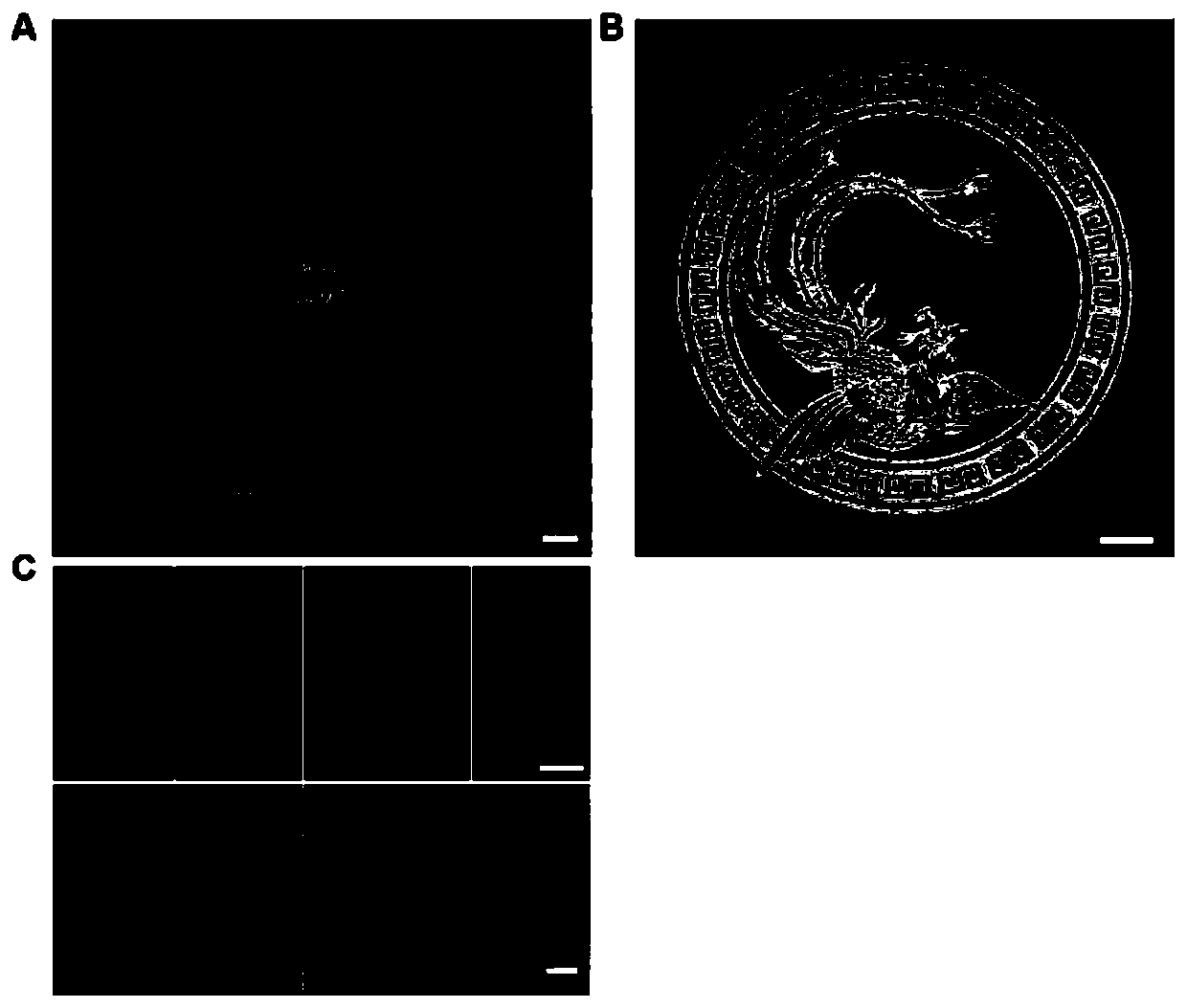

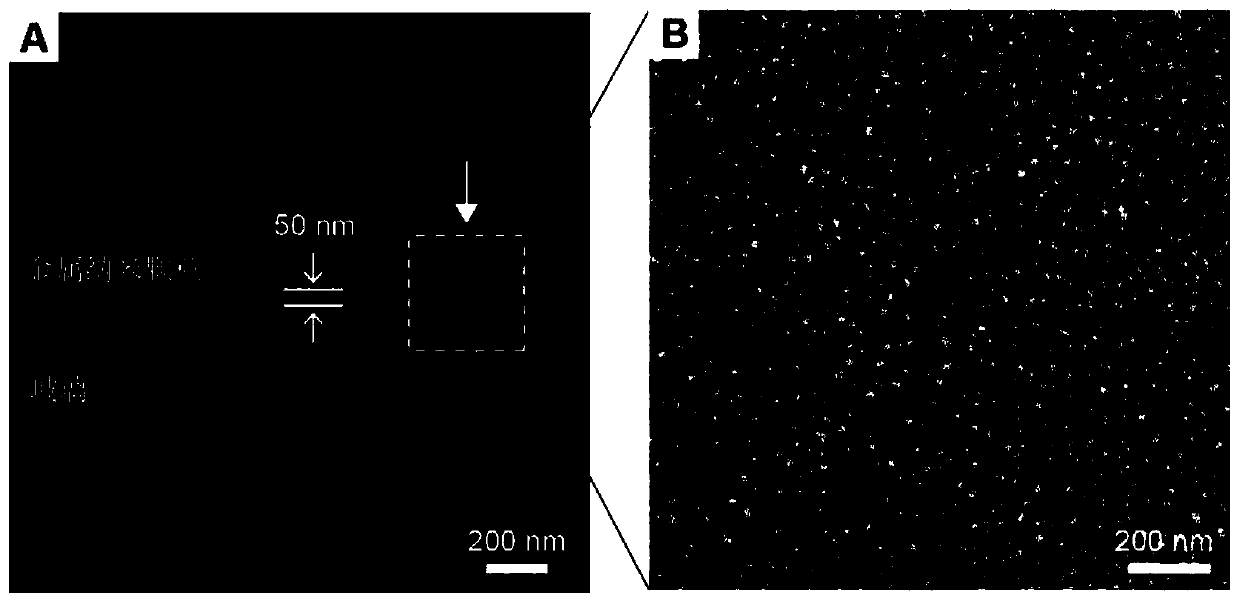

[0065]The HKUST-1 powder layer sample prepared above was placed on the sample stage for irradiation scanning with a nanosecond p...

Embodiment 3

[0068] Metal-organic framework compound crystal powders containing Bi3+, Cd2+, Zn2+, Pb3+, In3+, Fe3+, Co2+ and Ni2+ were prepared by solvothermal method. After the impurities were removed by solvent washing, the solvent in the powder was removed by heating to obtain a dry powder sample. The crystal powder diffraction peaks obtained by X-ray powder diffraction were matched with the simulated diffraction peaks corresponding to the respective crystal models, and it was verified that the metal organic framework compound obtained was a pure phase.

[0069] Fill the obtained metal organic framework material powder in a metal foil with a circular cavity according to the method in Example 2, the thickness of the metal foil is 10 μm, and the diameter of the cavity is 16 mm, and 8 mg of Metal-organic framework compound powder is evenly pressed between two glass sheets, and the two ends of the glass sheets are fixed with adhesive tape to form a sample with a sandwich structure.

[0070]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com