Magnetic metal oxide microsphere in core-shell structure and its prepn process

A magnetic metal, core-shell structure technology, applied in the preparation method of peptides, ferrous oxides, chemical instruments and methods, etc., can solve the problems of complicated column packing, time-consuming and laborious operation, etc. Easy to obtain, controllable particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

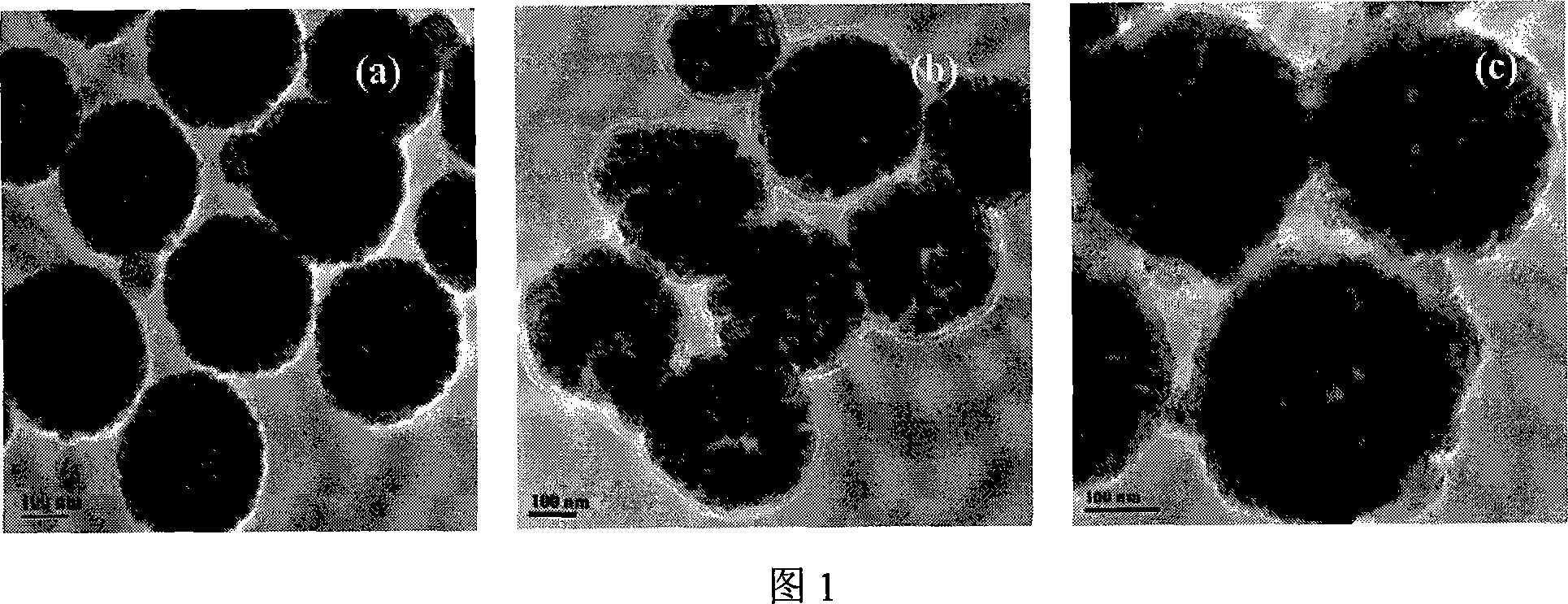

Embodiment 1

[0023] Weigh 0.1g of ferric oxide microspheres with an average particle size of 300nm and disperse them in 1M hydrochloric acid aqueous solution, ultrasonically treat them for 5min, then use a magnet to separate and wash them for 3 times, and disperse the washed microspheres in 40mL of 20g / L glucose aqueous solution And in 180 ℃ hydrothermal reaction 6h. The product was separated with a magnet, and washed 4 times with deionized water, and the obtained magnetic carbon spheres Fe 3 o 4 @C was vacuum-dried for later use.

[0024] Weigh 0.5g of aluminum isopropoxide and dissolve it in 20mL of alcohol / water (volume ratio 4 / 1) solution and stir for 10min, add 0.2g of Fe obtained above 3 o 4 @C microspheres were ultrasonically oscillated for 2 min, and then the Fe adsorbed on the aluminum hydroxide oligomer was 3 o 4 The @C microspheres were separated, washed with ethanol three times, and finally calcined at 600°C in nitrogen for 1 hour to obtain microspheres with an inner core ...

Embodiment 2

[0026] Weigh 0.2g of iron ferric oxide microspheres with an average particle size of 200nm and disperse them in 0.5M hydrochloric acid aqueous solution, ultrasonically treat them for 8min, then use a magnet to separate and wash them for 5 times, and disperse the washed microspheres in 20mL of 20g / L glucose aqueous solution And in 180 ℃ hydrothermal reaction 10h. The product was separated with a magnet, and washed 3 times with deionized water, and the obtained magnetic carbon spheres Fe 3 o 4 @C was vacuum-dried for later use.

[0027] Weigh 0.7g zirconium isopropoxide and dissolve it in 20mL alcohol / water (volume ratio 4 / 1) solution and stir for 10min, add 0.1g Fe obtained above 3 o 4 @C microspheres were ultrasonically oscillated for 3 min, and then the Fe adsorbed zirconium hydroxide oligomers were 3 o 4 The @C microspheres were separated, washed with ethanol for 3 times, and finally calcined at 500°C for 2 hours in nitrogen to obtain microspheres with a core of ferric ...

Embodiment 3

[0029] Weigh 0.3g of iron ferric oxide microspheres with an average particle size of 600nm and disperse them in 2M hydrochloric acid aqueous solution, ultrasonically treat them for 10min, then use a magnet to separate and wash them for 4 times, and disperse the washed microspheres in 80mL of 20g / L glucose aqueous solution And at 190 ° C hydrothermal reaction for 5h. The product was separated with a magnet, and washed 3 times with deionized water, and the obtained magnetic carbon spheres Fe 3 o 4 @C was vacuum-dried for later use.

[0030] Weigh 1.0g of indium isopropoxide and dissolve it in 20mL of alcohol / water (volume ratio 4 / 1) solution and stir for 10min, add 0.2g of Fe obtained above 3 o 4 @C microspheres were ultrasonically oscillated for 2 min, and then the Fe adsorbed on the indium hydroxide oligomer was 3 o 4 The @C microspheres were separated and washed with ethanol for 3 times, and finally calcined at 700°C for 50-80 minutes in nitrogen to obtain microspheres w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com