Waste salt recycling process and special device thereof

A special device and resource-based technology, used in transportation and packaging, chemical instruments and methods, and solid waste removal, etc., can solve the problems of continuous and stable operation of equipment bonding, poor temperature control, etc. Uniformity, high purity, and the effect of preventing the leakage of furnace gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

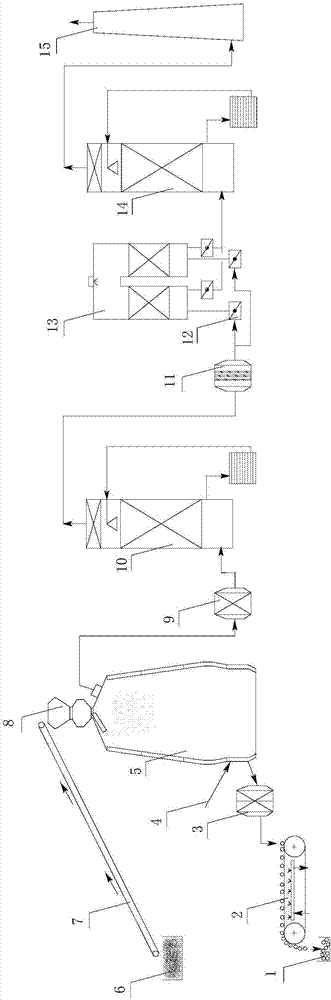

[0036] The components of waste salt produced by a pesticide and pharmaceutical intermediate manufacturer are NaCl 97%, water 1.74%, benzoic acid 0.23%, 3,4-dichloro-5-carboxylate sodium isothiazole 0.12%, p-toluenesulfonic acid 0.21%, ammonia solution 0.35%, toluene 0.35%. The main operating technical parameters of the equipment and process are: the control temperature of the molten salt furnace is: drying, preheating section 200°C, melting section 850°C, molten salt dripping section 1000°C, molten salt collecting section 900°C, waste salt in the furnace The residence time is 8S; the outlet temperature of molten salt furnace tail gas is 200°C, the temperature of RTO furnace inlet air is 50°C, the temperature of organic waste gas incineration chamber is 800°C, the temperature of exhaust gas from RTO furnace is 100°C, and the exhaust temperature of chimney exhaust gas after passing through the alkali washing tower is 40°C. After purification by the molten salt furnace, the NaCl...

Embodiment 2

[0038] The composition of waste salt produced by a pigment production enterprise is 94.86% of sodium sulfate, 1.74% of 1,4-diaminoanthraquinone, 1.21% of 1,4-dihydroxyanthraquinone, and 2.19% of other organic impurities. The main operating technical parameters of the equipment and process are: the control temperature of the molten salt furnace is: drying, preheating section 250°C, melting section 900°C, molten salt dripping section 1050°C, molten salt collecting section 920°C, waste salt in the furnace The residence time is 10S; the outlet temperature of molten salt furnace tail gas is 200°C, the temperature of RTO furnace inlet air is 50°C, the temperature of organic waste gas incineration chamber is 800°C, the temperature of exhaust gas from RTO furnace is 100°C, and the exhaust temperature of chimney exhaust gas after passing through the alkali washing tower is 40°C. After purification by the molten salt furnace, the sodium sulfate content of the net salt is 100%, and TOC (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com