Device for adding fuel additives to steam-injection boiler and adding method

A fuel additive and steam injection boiler technology, which is applied in the field of heavy oil thermal recovery, can solve problems such as reducing fuel combustion efficiency, and achieve the effects of improving boiler thermal efficiency, improving combustion efficiency, and reducing fuel viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

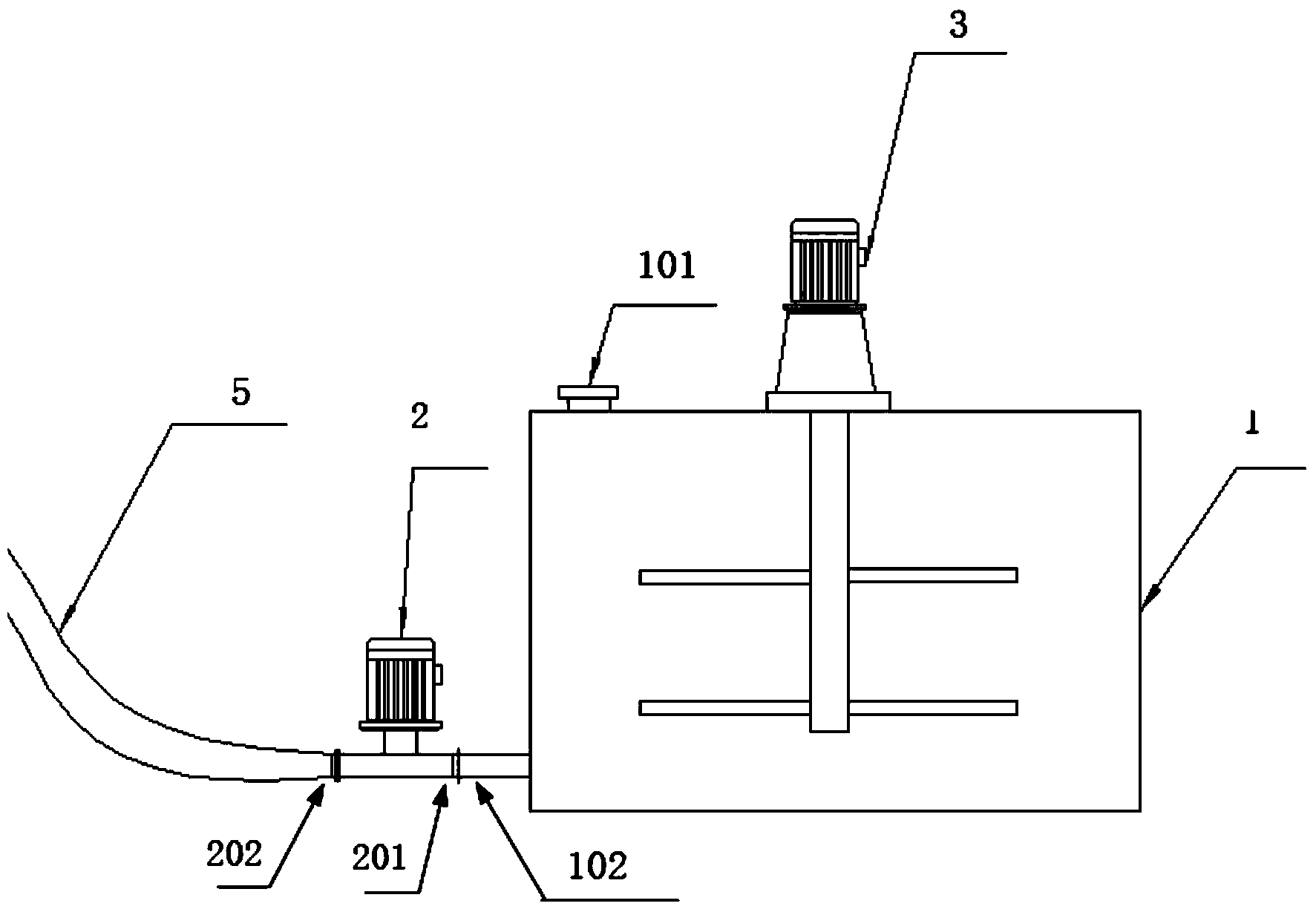

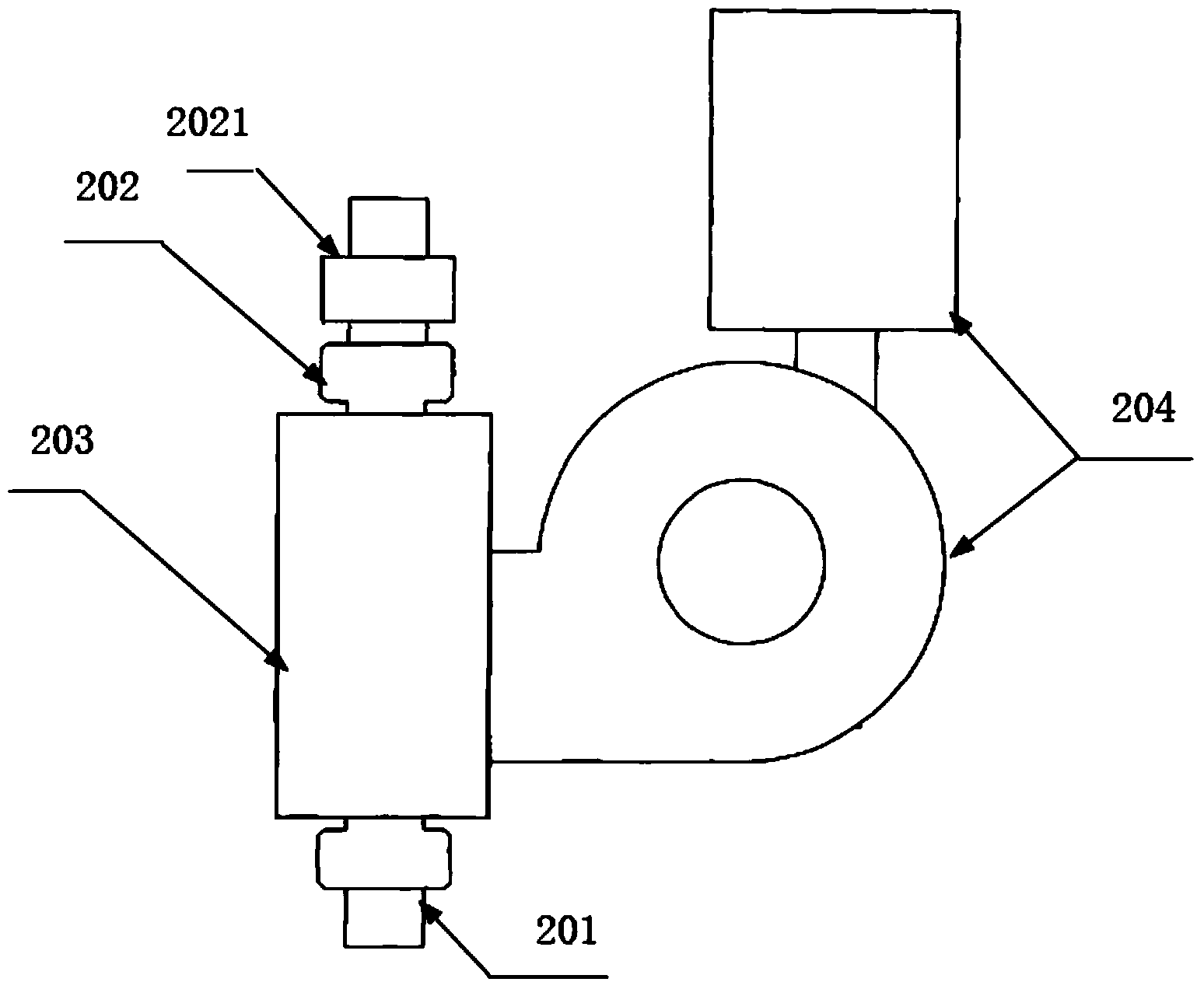

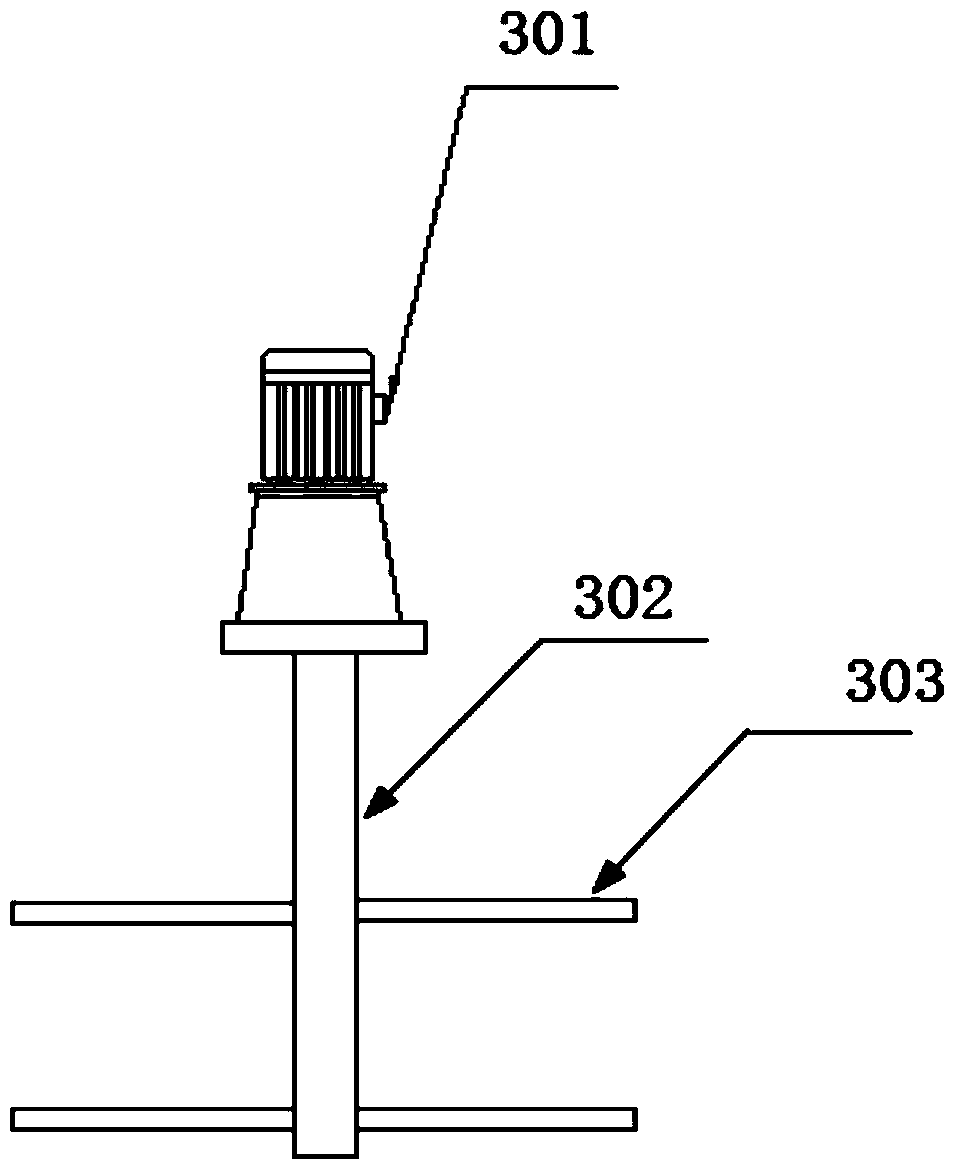

[0039] Example 1 is a fuel additive adding device for a steam injection boiler provided by the present invention. figure 1 It is a schematic diagram of the structure of the steam injection boiler fuel additive adding device and the connection relationship of each component in Embodiment 1 of the present invention. like figure 1 As shown, the steam injection boiler fuel additive adding device provided by the present invention includes a medicine box 1, a proportional pump 2, an agitator 3, and a connecting pipeline 5, wherein:

[0040]The medicine box 1 can be used to contain fuel additives and diluents, and the medicine box 1 can be a box structure such as a cuboid or a cylinder. The medicine box 1 includes a medicine filling port 101 and a medicine outlet 102 . The dosing port 101 can be used for adding fuel additives and diluents. The medicine filling port 101 can be arranged on the top or the upper half of the side wall of the medicine box 1 . The drug outlet 102 can be...

Embodiment 2

[0052] Embodiment 2 is an embodiment of the second fuel additive adding device for a steam injection boiler provided by the present invention. Figure 5 It shows the structure of the fuel additive adding device for the steam injection boiler in Embodiment 2 of the present invention and the connection relationship of each component. like Figure 5 As shown, the structure of the steam injection boiler fuel additive addition device provided in Embodiment 2 of the present invention and the connection relationship of each component are the same as in Embodiment 1, the difference is that the steam injection boiler fuel additive addition device also includes an atomization device 6, wherein:

[0053] The atomizing device 6 can be used to atomize the fuel additive, and the structure of the atomizing device 6 includes an input end for inputting the fuel additive and an output end for spraying the fuel additive. The input end 6 of the atomization device is connected to the output port ...

Embodiment 3

[0093] Example 3 is an example of using the method of the present invention to uniformly add the fuel additive to the fuel.

[0094] There are 24 tons of liquid fuel that need to be burned in the furnace of the steam injection boiler within 24 hours. The boiler has a thermal efficiency of 78% before fuel additives are used. The fuel additive used in Example 3 is a diesel oil saver. The fuel additive is in the form of solid powder, bottled, 70 grams per bottle, and the addition ratio of the fuel additive to fuel is 70 grams per ton. According to the above calculation, 24 bottles of the fuel additive are needed to burn the 24 tons of liquid fuel. There is no special requirement on the dilution ratio of the fuel additive, and it can be melted in solid powder form. In order to fully mix the fuel additive with the fuel, the mixing ratio of the fuel additive and the diluent in this embodiment is: bottle / 10L, that is, 70 g / 10 liters. The diluent adopts diesel oil with a temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com