Method for acidolysis and reduction of ferric iron by titanium dioxide to improve quality of titaniferous solution through sulfuric acid method

A technology of ferric iron and titanium dioxide, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of heat dissipation, process quality decline, rapid response, etc., and achieve the effect of saving resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

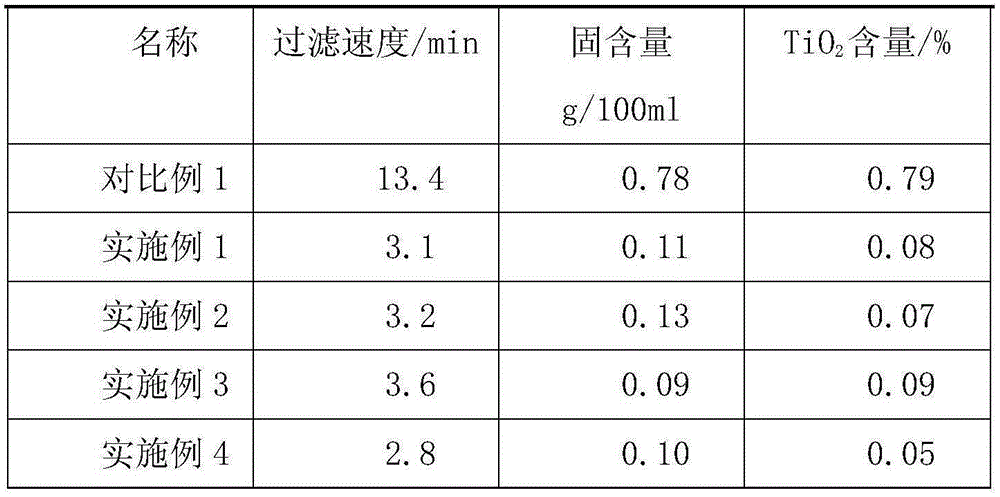

Examples

Embodiment 1

[0023] Adding the sulfuric acid mass concentration to the solid phase after the reaction of ilmenite and concentrated sulfuric acid is 19% titanium white waste acid and tap water, and the acid-titanium ratio is controlled at 1.8, and the acid-titanium ratio is the volume concentration of sulfuric acid in the solution (g / L ) to the volume concentration (g / L) of titanium dioxide; the flow rate ratio of titanium dioxide waste acid and tap water is controlled at 0.4, and the temperature of the reaction solution is less than 70°C; after adding waste acid and tap water, start the compressed air to stir, Make the reaction solution as uniform as possible, and make the temperature of the reaction solution less than 70°C. When the temperature of the reaction solution tends to rise, increase the air volume of the air stirring to make the temperature drop below 70°C, and stop adding waste acid and tap water at the same time; The final titanium solution with an acid-titanium ratio of 1.8 is...

Embodiment 2

[0025] Adding sulfuric acid mass concentration to the solid phase after the reaction of ilmenite and concentrated sulfuric acid is 20% titanium white waste acid and tap water, and the acid-titanium ratio is controlled at 1.9, and the acid-titanium ratio is the volume concentration of sulfuric acid in the solution (g / L ) to the volume concentration (g / L) of titanium dioxide; the flow rate ratio of titanium dioxide waste acid and tap water is controlled at 0.5, and the temperature of the reaction solution is less than 70°C; after adding waste acid and tap water, open the compressed air to stir, so that the reaction The solution is as uniform as possible, and the temperature of the reaction solution is lower than 70°C. When the temperature of the reaction solution tends to rise, increase the air volume of the air stirring to make the temperature drop below 70°C, and stop adding waste acid and tap water at the same time; The titanium solution with a titanium acid ratio of 1.9 is pu...

Embodiment 3

[0027] The solid phase after the reaction of ilmenite and concentrated sulfuric acid is added with sulfuric acid mass concentration to be 21% titanium white waste acid and tap water, and the acid-titanium ratio is controlled at 2.0, and the acid-titanium ratio is the volume concentration of sulfuric acid in the solution (g / L ) to the volume concentration (g / L) of titanium dioxide; the flow rate ratio of titanium dioxide waste acid and tap water is controlled at 0.6, and the temperature of the reaction solution is less than 70°C; after adding waste acid and tap water, open the compressed air to stir, so that the reaction The solution is as uniform as possible, and the temperature of the reaction solution is lower than 70°C. When the temperature of the reaction solution tends to rise, increase the air volume of the air stirring to make the temperature drop below 70°C, and stop adding waste acid and tap water at the same time; The titanium solution with a titanium acid ratio of 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com