Fluorine doping method of cerium-based rare earth polishing powder

A rare earth polishing powder, cerium-based technology, applied in the fluorine-doped field of cerium-based rare earth polishing powder, can solve the problems affecting the polishing rate and precision of rare earth polishing powder, affecting the crystal structure of the final product, and difficult to control the particle size and particle size distribution. The particle size and particle size distribution are easy to control, the polishing accuracy is easy, and the polishing accuracy is controlled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepare 2.0mol / L lanthanum cerium chloride solution, 2.5mol / L ammonium carbonate solution and 1.0mol / L fluosilicic acid solution respectively. In the state of continuous stirring, the above-mentioned raw material solution is continuously added into the reaction kettle in parallel. Adjust the flow rate of the fluosilicic acid solution, control the F / TREO to 5%, adjust the flow rate of the ammonium carbonate solution, control the pH of the reaction system to 8.50±0.05, and control the temperature of the reactor to 40°C. After the reaction was completed, it was aged for 1 h. The aged slurry is filtered, washed, and dried at 90° C. to obtain a polishing powder precursor.

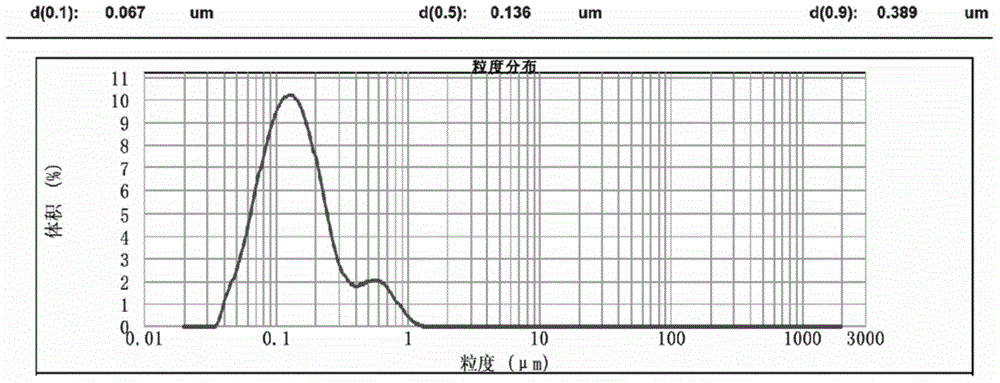

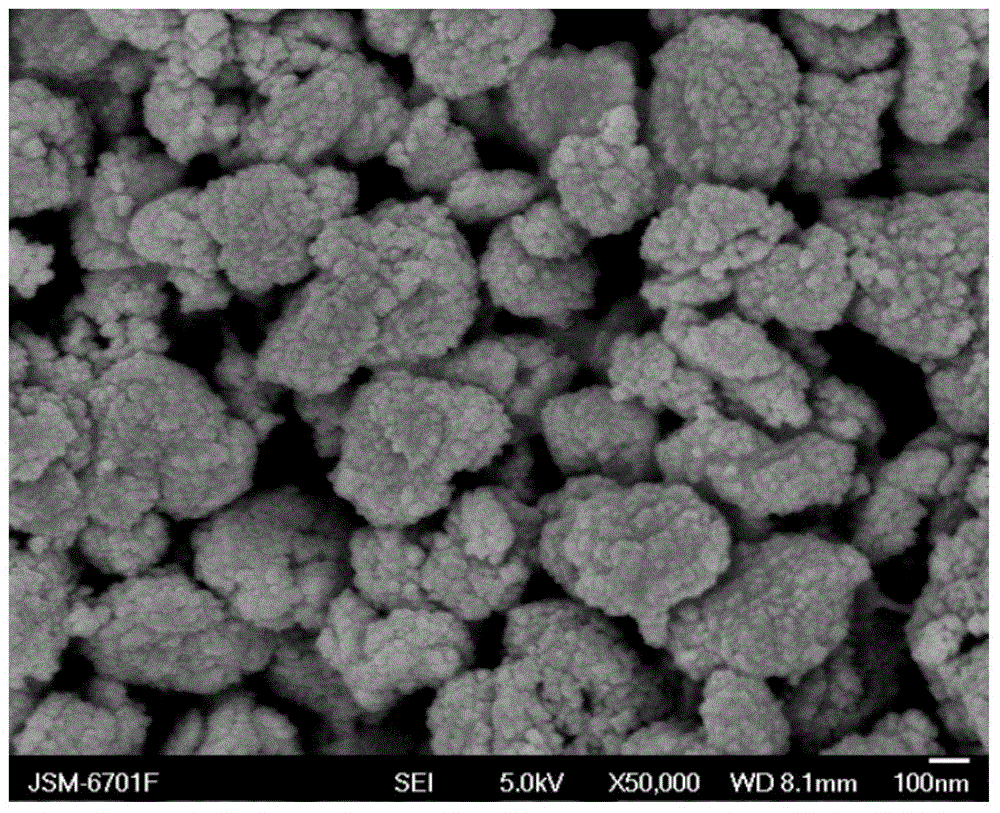

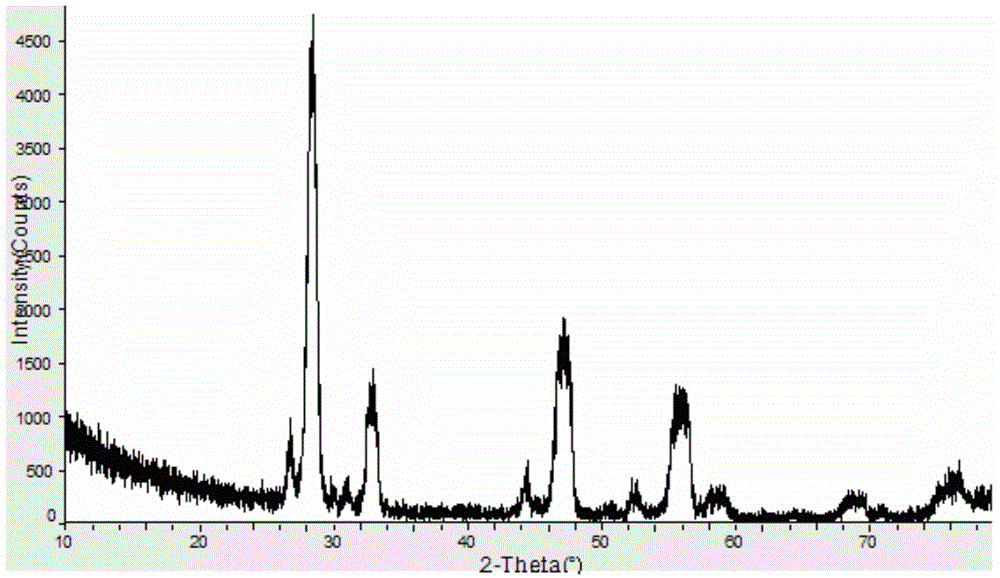

[0025] The prepared polishing powder precursor was calcined at 900° C. for 3 h to obtain the finished polishing powder. Particle size analysis, scanning electron microscope analysis and XRD analysis were carried out on the sample, and the analysis results were as follows: Figure 1~3 As shown, the part...

Embodiment 2

[0027] Prepare 1.5 mol / L lanthanum cerium neodymium chloride solution, 2.0 mol / L ammonium bicarbonate solution and 0.5 mol / L ammonium fluoride solution respectively. Under the condition of continuous stirring, the above-mentioned raw material solution is continuously added into the reactor in parallel flow. Adjust the flow rate of ammonium fluoride solution, control the F / TREO to 6%, adjust the flow rate of ammonium carbonate, control the pH of the reaction system to 8.00±0.05, and control the temperature of the reaction kettle to 50°C. After the reaction was completed, it was aged for 1 h. The aged slurry is filtered, washed, and dried at 90° C. to obtain a polishing powder precursor.

[0028] The prepared polishing powder precursor was calcined at 950° C. for 2 h to obtain the finished polishing powder. The particle size of the sample D50 = 0.857 μm.

Embodiment 3

[0030] Prepare 2.5mol / L lanthanum cerium nitrate solution, 4.0mol / L sodium hydroxide solution and 1.5mol / L hydrofluoric acid solution respectively. Under the condition of continuous stirring, the above-mentioned raw material solution is continuously added into the reactor in parallel flow. Adjust the flow rate of ammonium fluoride solution, control the F / TREO to 6.5%, adjust the flow rate of sodium hydroxide, control the pH of the reaction system to 9.00±0.05, and control the temperature of the reaction kettle to 55°C. After the reaction was completed, it was aged for 1.5h. The aged slurry is filtered, washed, and dried at 90° C. to obtain a polishing powder precursor.

[0031] The prepared polishing powder precursor was calcined at 1000° C. for 2 h to obtain the finished polishing powder. The particle size of the sample D50 = 1.235 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com