MVR continuous evaporative crystallization system

An evaporative crystallization and crystallizer technology, applied in the field of MVR continuous evaporative crystallization system, can solve the problems of underutilization, energy waste, environmental pollution, etc., and achieve the effect of safe and reliable material feeding and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

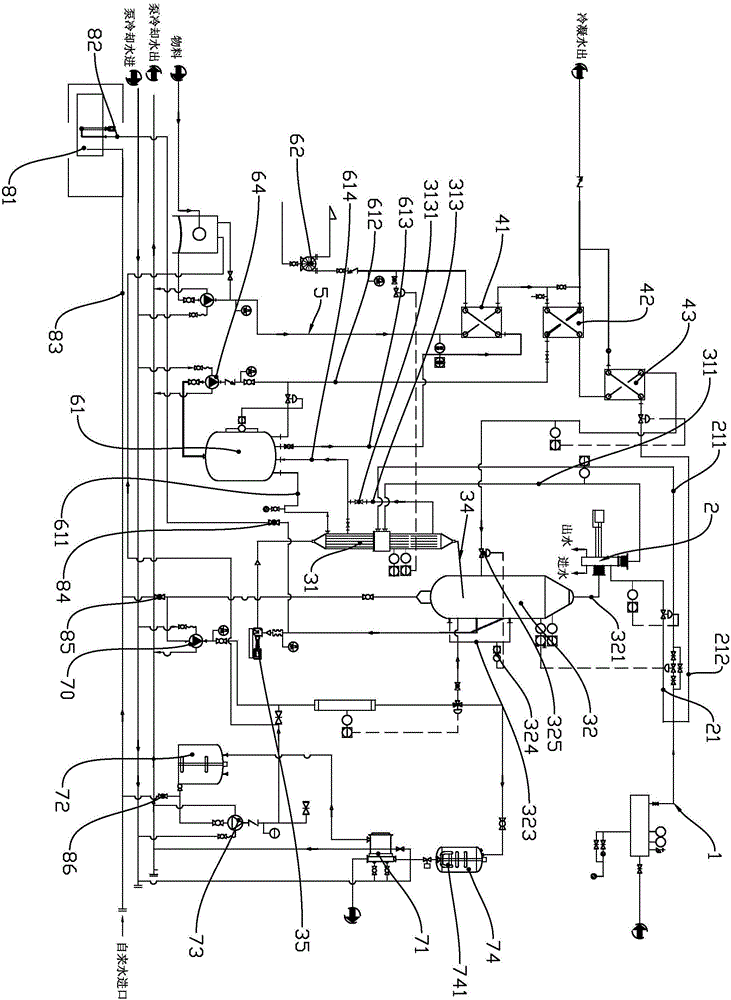

[0022] Referring to accompanying drawing 1, a kind of MVR continuous evaporative crystallization system disclosed by the present invention includes a heating system, an evaporative crystallization system, a crystallization separation system and a condensation system, and the heating system includes a raw steam compensation pipeline 1, a steam compressor 2 And a material preheating device, the evaporation crystallization system includes a circulation evaporator 31 and a crystallizer 32, the circulation evaporator 31 and the crystallizer 32 are all connected to the steam compressor 2 through the secondary steam pipes 311, 321, and the steam compressor 2 is connected to the two After the secondary steam is compressed, its pressure and saturation temperature are increased, and the enthalpy value is increased, so that the secondary steam generated by the circulating evaporator and crystallizer can be effectively used to achieve the purpose of energy saving; The first branch pipe 211...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com