Automatic boring tapping all-in-one machine

A technology of tapping and drilling mechanism, which is applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of complex structure and control system, poor workpiece positioning accuracy, and reduced work efficiency, so as to achieve a high degree of automation and a high degree of workpiece accuracy. Accurate positioning, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

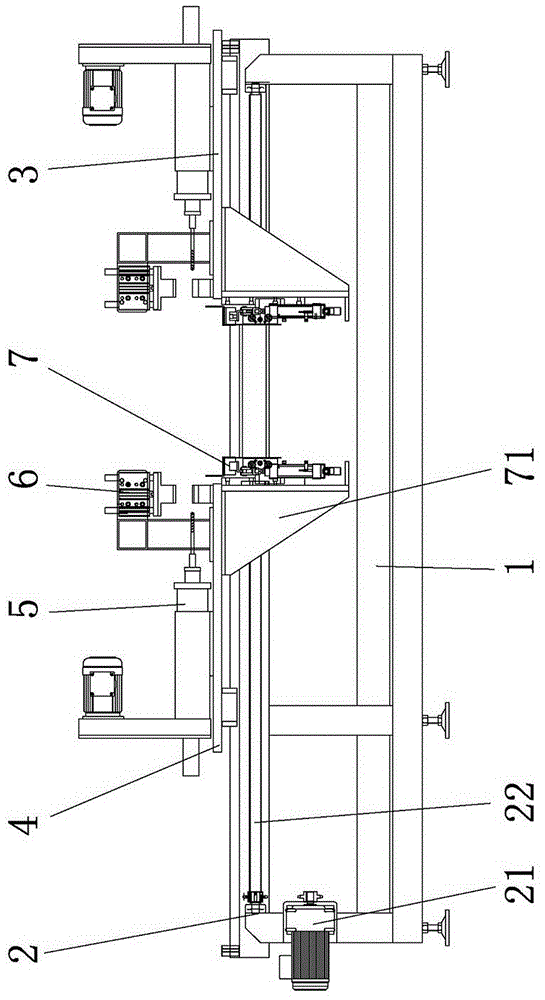

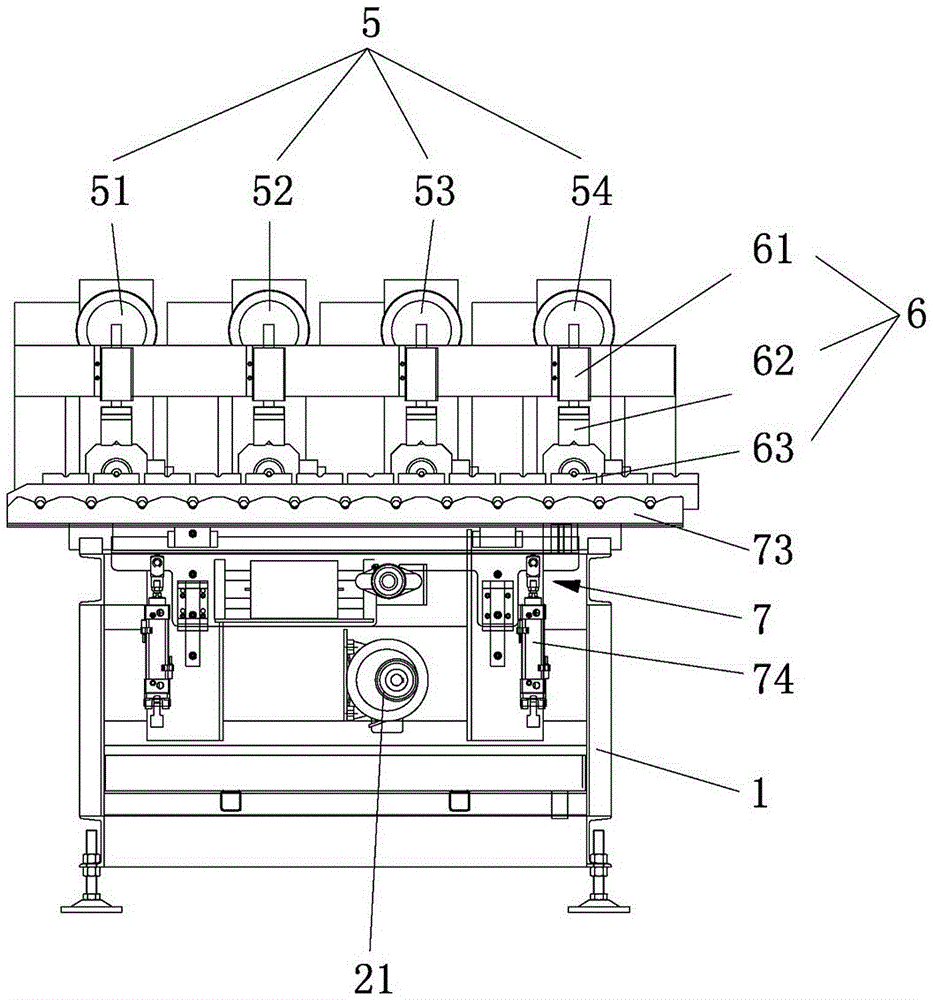

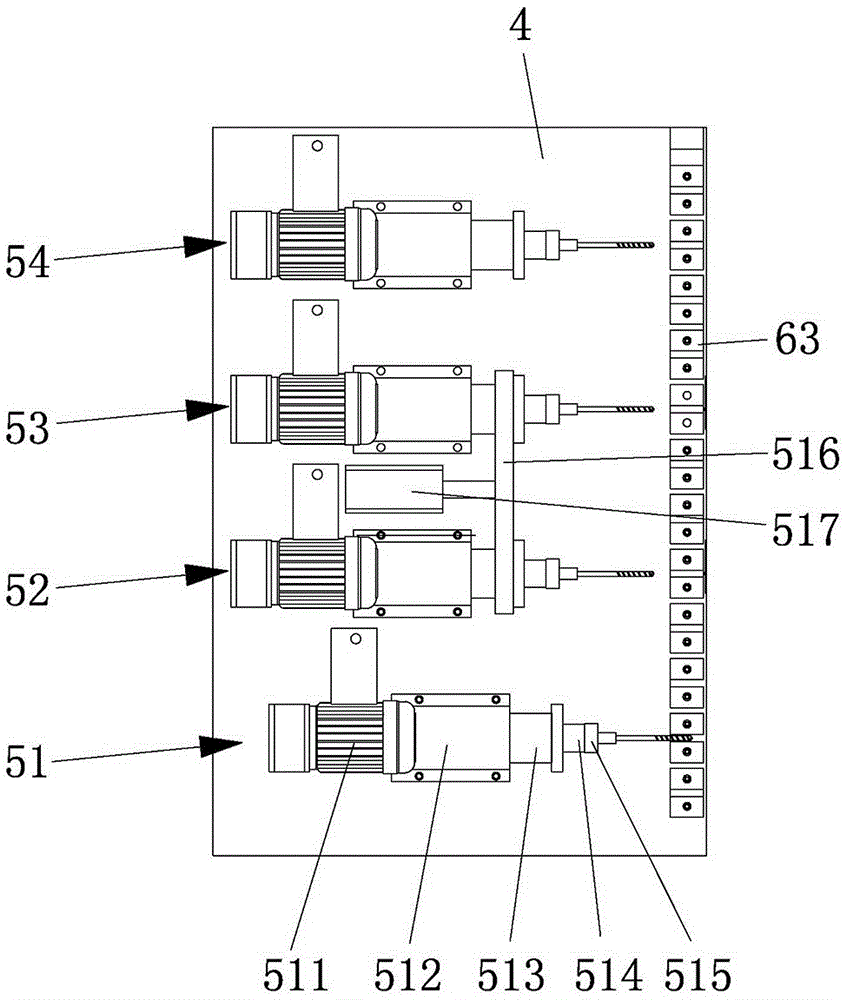

[0023] Example: such as Figure 1 to Figure 5 As shown, an automatic drilling and tapping integrated machine includes a frame 1, and the frame 1 is provided with a fixed workbench 3, a movable workbench 4 and a driving device 2, and the fixed workbench 3 is fixedly installed on the On the frame 1, the movable table 4 is movably installed on the frame 1, and the driving device 2 drives the movable table 4 to move along the frame 1 to adjust the The distance between movable workbench 4 and fixed workbench 3. The driving device 2 includes a motor 21 and a driving screw 22 , the driving screw 22 is rotatably arranged on the frame, and its axial direction is the same as the moving direction of the movable worktable 4 . The bottom of the movable workbench 4 is fixedly connected with a transmission block, and the transmission block is connected with the transmission screw mandrel 22. When the transmission screw mandrel 22 rotates, the transmission block drives the movable workbench ...

Embodiment 2

[0040] Embodiment 2: as Figure 6 As shown, the difference from Embodiment 1 is that translation guide rails 78 are provided with translation stoppers, and the translation stoppers are located on both sides of the translation slider 79, and the translation slider 79 is inside the two translation stoppers. The moving distance is equal to the distance from one station to the next station. The translation limit block includes a fixed limit block 781 and a movable limit block 782. The fixed limit block 781 is fixedly installed on the translation guide rail 78, and the movable limit block 782 is movably installed on the translation guide rail 78, and the movable limit block 782 is fixed on the translation guide rail 78 by a locator, and the distance between the fixed limit block 781 and the movable limit block 782 is adjusted as required. A distance sensor is arranged between the fixed limit block 781 and the movable limit block 782, and an alarm can be issued once the distance cha...

Embodiment 3

[0041] Embodiment 3: The difference from the above embodiments is that the movable workbench 4 and the fixed workbench 3 are also provided with a limit device, and the limit device ensures that the translation distance of the translation frame 73 remains unchanged during the forward and backward translation process. Described spacer device comprises the front spacer bar that is installed on the mounting frame 71, rear spacer bar, upper inductor and lower sensor, and front spacer bar is positioned at the starting position place of translation frame 73, and promptly translation frame 73 is in The positions of the lowest position and the most forward position; the rear limit rod is located at the position where the translation frame 73 moves backwards by one station when it rises from the initial position to the highest position, and the front limit rod and the rear limit rod are all connected with the front drive separately. The limit cylinder for the movement of the limit rod an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com