Automatic high-efficiency plastic crusher

A pulverizer, high-efficiency technology, applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of waste, unhygienic, large dust, etc., and achieve the effect of safe feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

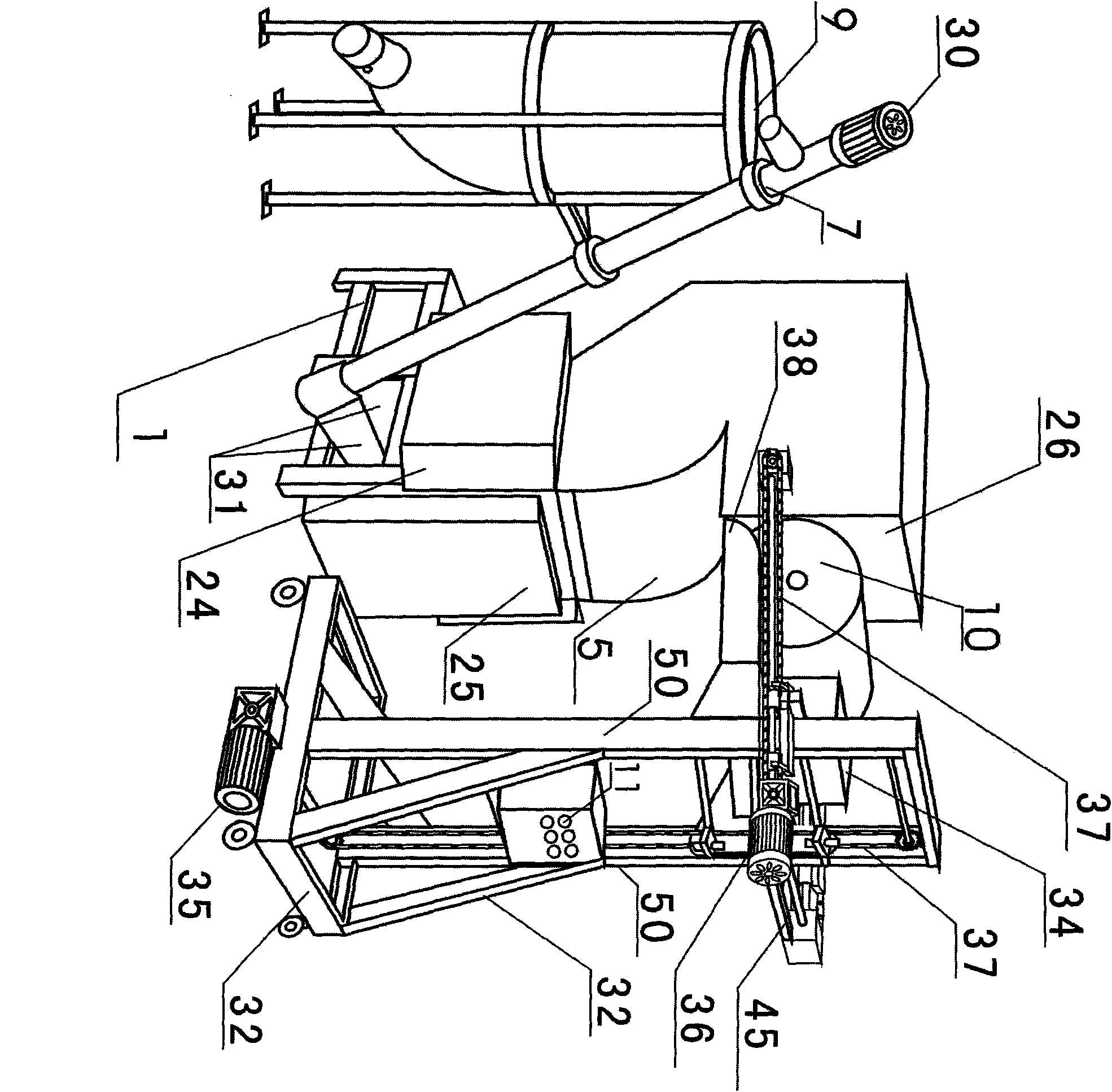

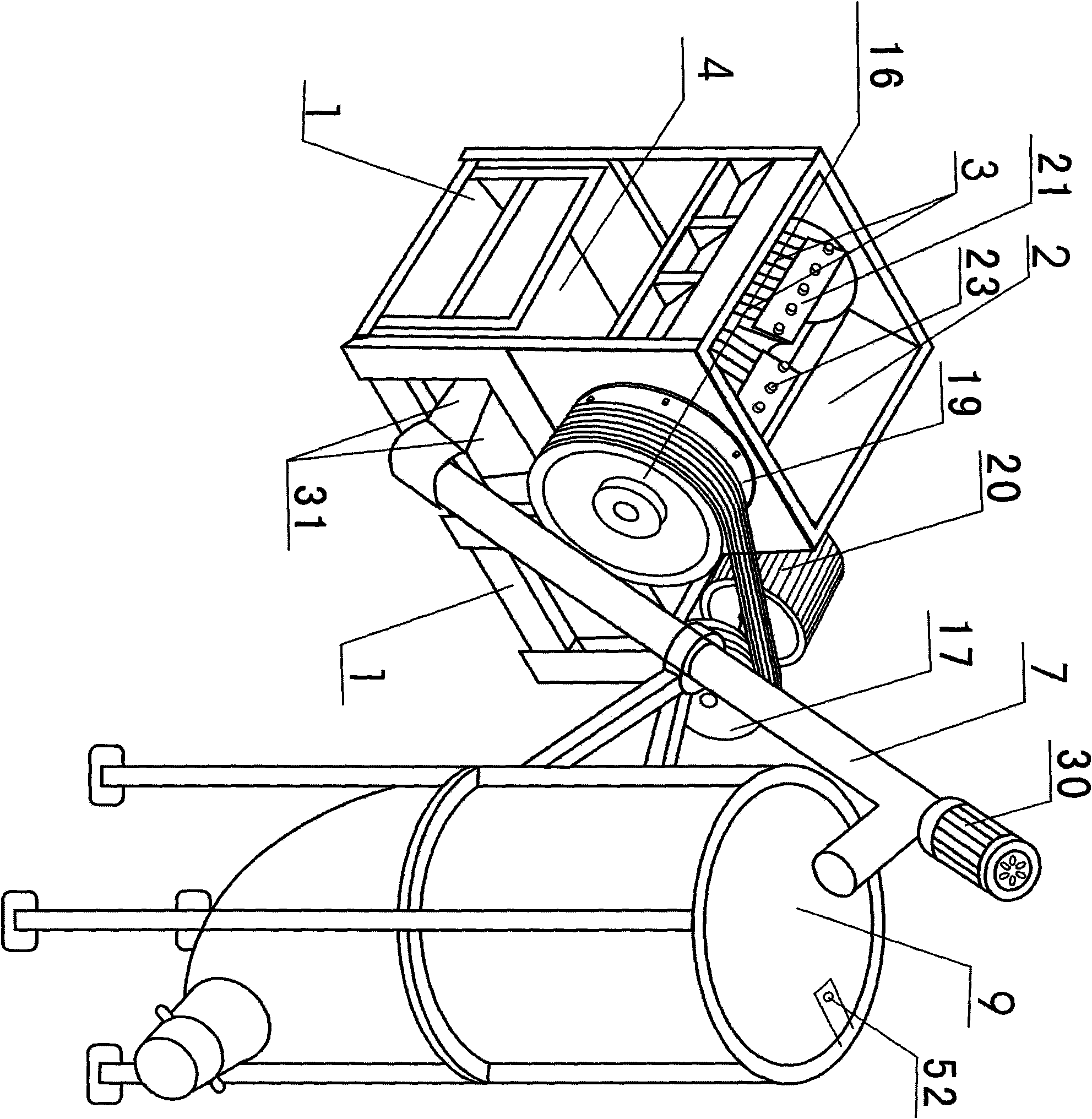

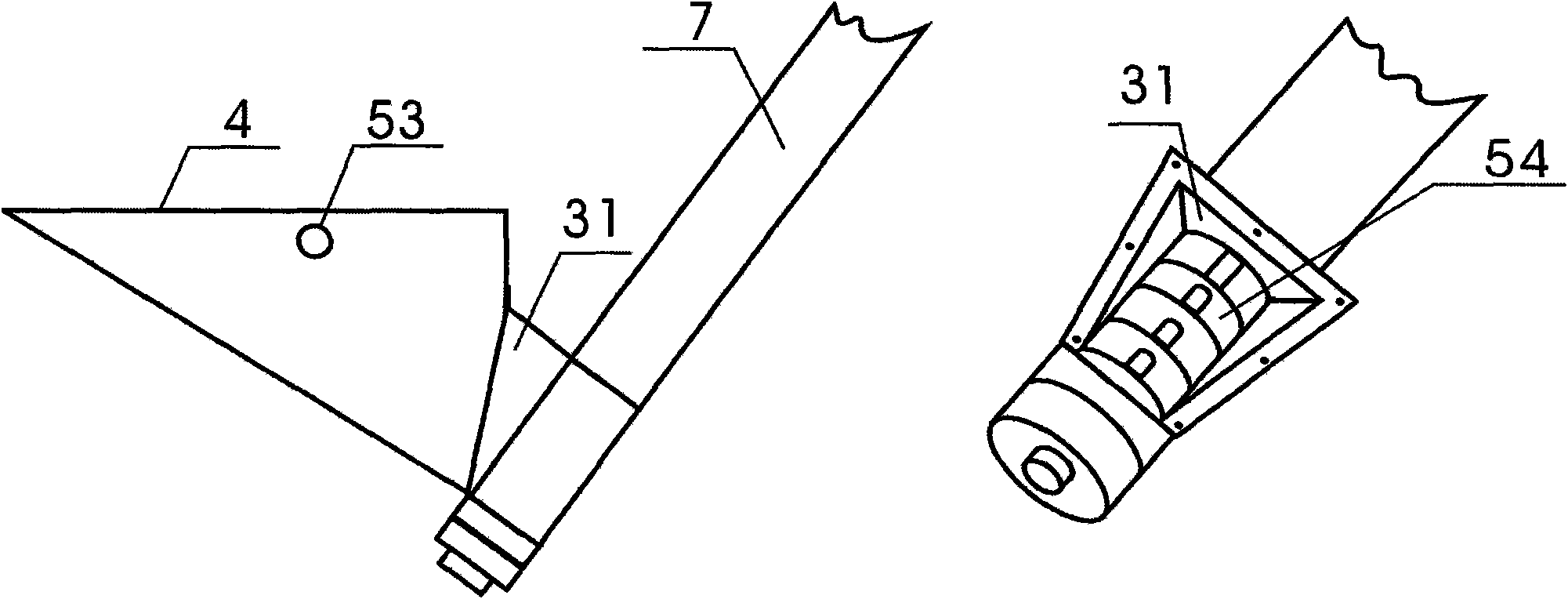

[0032] Such as Figure 1 to Figure 7 As shown, an automatic high-efficiency plastic shredder is characterized in that it includes a shredder host base frame 1, a shredder crushing chamber 2, a shredder cover 5, a shredder host transmission device 3, a blanking bucket 4, and a screen. Device 6, feeding screw rod 7, feeding lifting device 8, storage tank 9, distribution box 11, the main engine transmission device 3 of the pulverizer includes a pulverizing knife seat 15, a pulverizing knife 21, and the two are combined together The fixed screw 23, the main drive motor 14 installed behind the base of the main engine, the large corner belt wheel 16, the small corner belt wheel 17, the corner belt wheel cover above the two wheels and the corner belt 20 sleeved on the two wheels, are located in the crushing The large flywheel 18 on the other side of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com