Palm sheet cutting and crushing device

A technology of cutting, crushing and browning, which is applied in the direction of grain processing, etc., can solve the problems of inability to quickly cut and decompose brown chips, fail to meet mass production, and low work efficiency, and achieve the protection of production personnel, feed safety, and complete crushing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

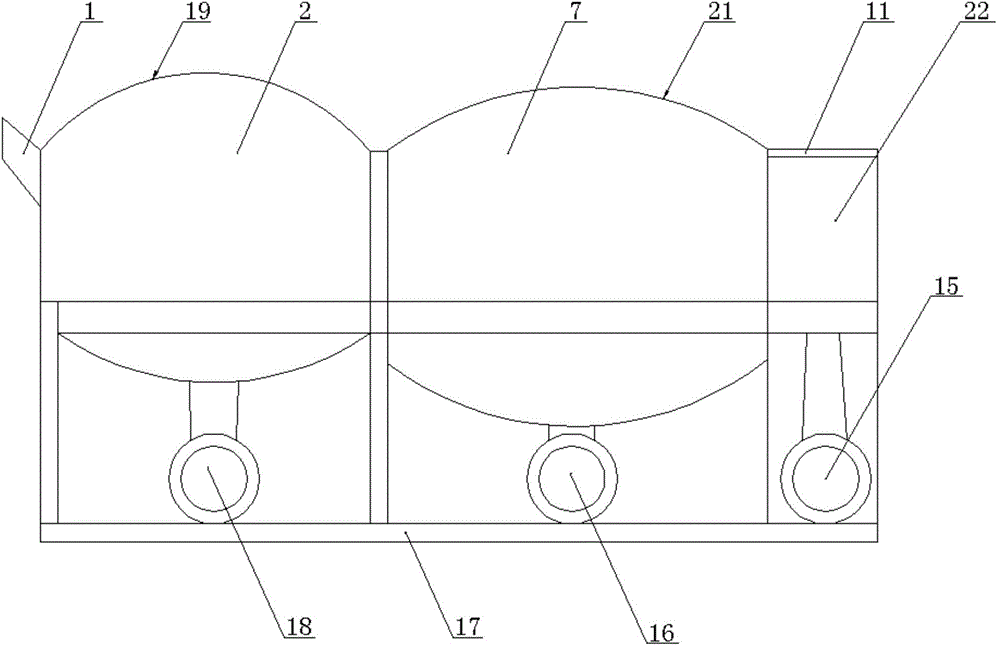

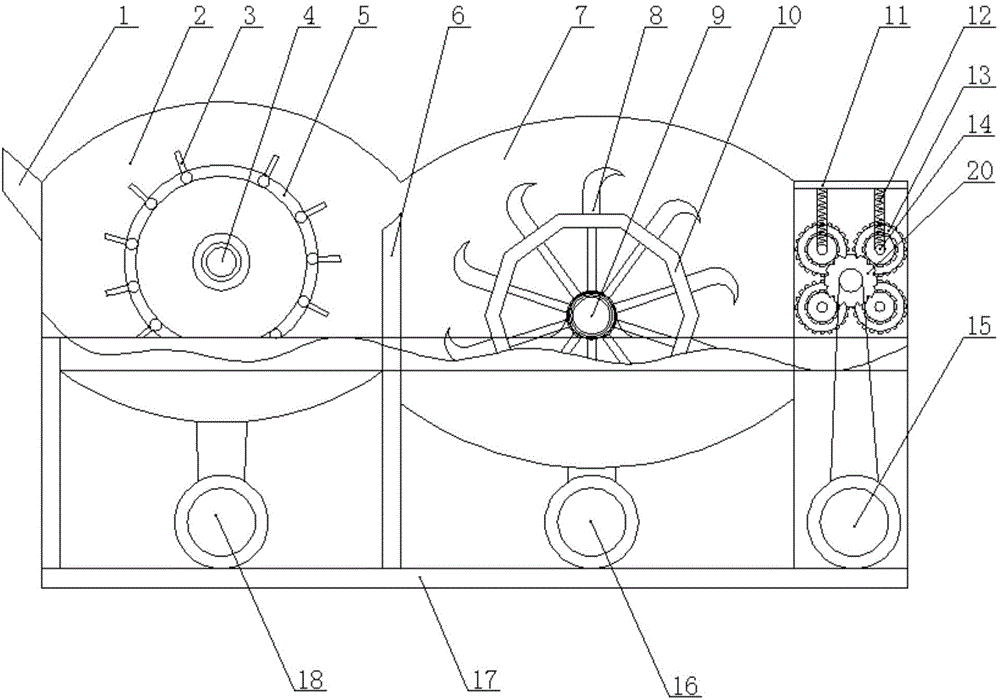

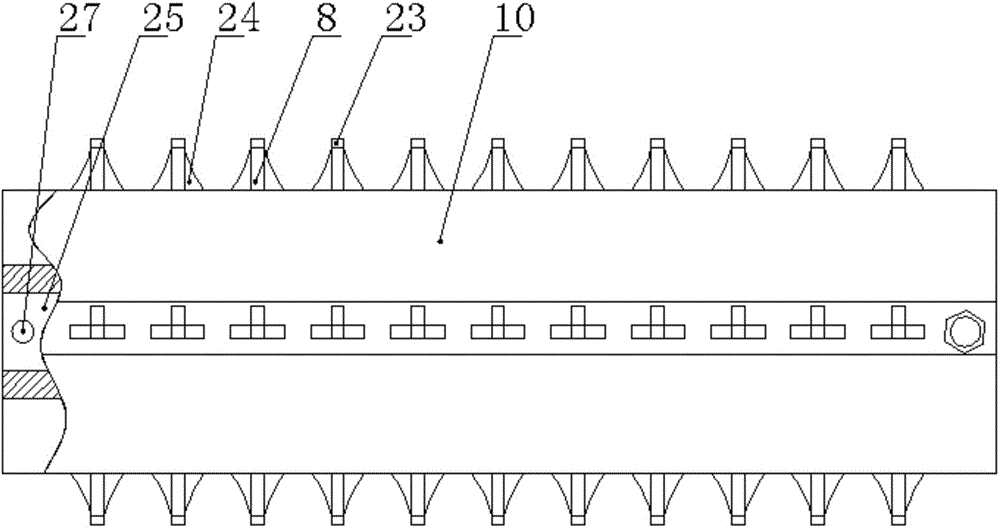

[0021] A brown chip cutting and crushing device is composed of a frame 17, a feeding mechanism, a decomposition mechanism and a discharge port 1; the feeding mechanism and the discharge port are respectively installed at the front and rear of the frame, and the decomposition mechanism is installed The middle part of the rack; the feed mechanism consists of at least four feed rollers 14, feed rollers 13 sleeved on the feed rollers, gears 20 installed at both ends of the feed rollers, bearings installed on the outside of the gears, and feed The transmission mechanism connected by the material roller; the decompos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com