Drilling device

A technology of drilling equipment and power device, applied in drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve the problem of low processing efficiency, low safety factor, cumbersome feeding or discharging, etc. problem, to achieve the effect of safe loading and unloading process and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

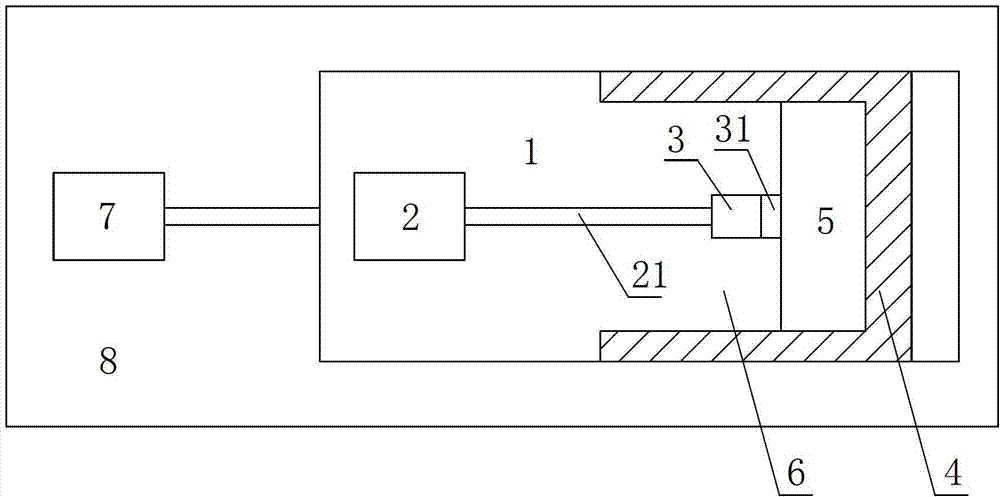

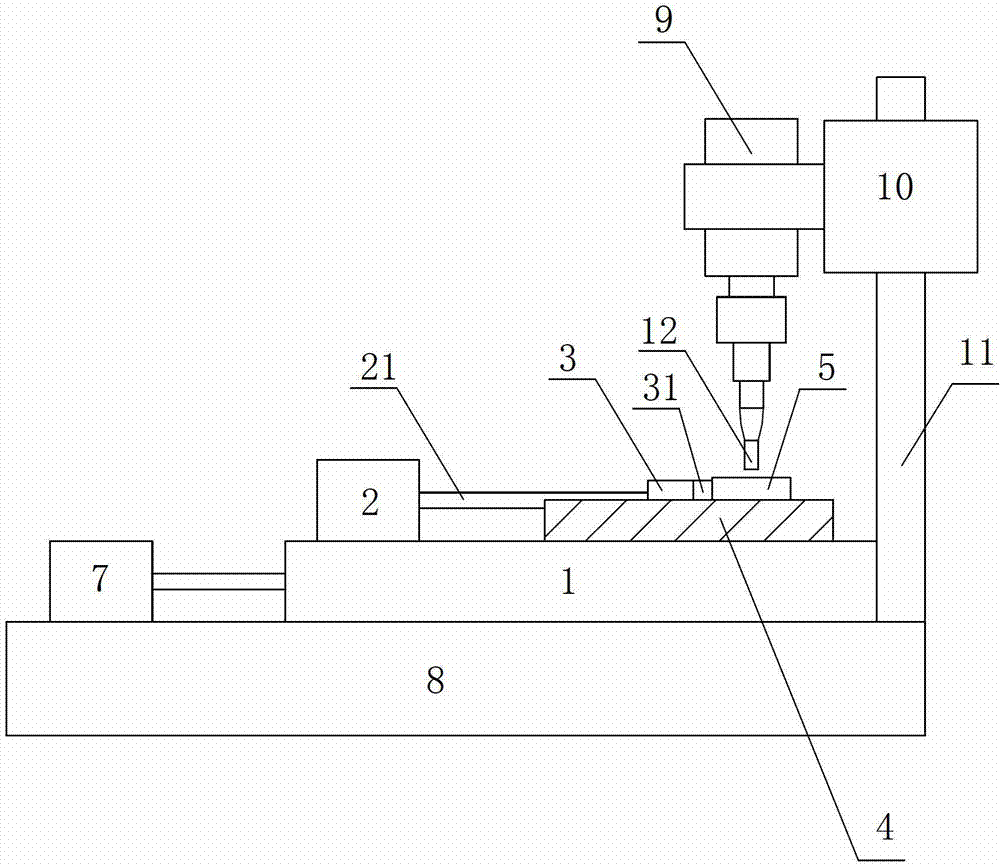

[0013] A drilling device is proposed, comprising a base 8, on which a guide post 11 and a first power unit 7 are fixed, and the guide post 11 is telescopically connected to a first motor 10, driven by the first motor 10, the first motor 10 moves along the The guide column 11 moves upward / downward, the first motor 10 is fixedly connected to the second motor 9, the second motor 9 rotates and connects to the drill bit 12, the first power unit 7 is telescopically connected to the slider 1, and the second power unit is fixed on the slider 1 2 and a limiting block 4, the limiting block 4 is provided with an accommodating space 6 for placing parts 5, and the second power device 2 drives the plug 3 into the accommodating space 6 and fixes the parts 5 in the accommodating space 6. A soft layer 31 is fixed at the front end of the plug 3 . Both the first power device 7 and the second power device 2 are pneumatic devices, and the front end of the piston rod 21 of the second power device 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com