Thermal insulation testing process and apparatus for simulating coal spontaneous combustion procedure

A coal spontaneous combustion and testing method technology, which is applied in the direction of fuel oil testing, thermal development of materials, and chemical analysis using combustion, etc., can solve the problems of heavy testing workload, long testing cycle, difficult to repeat testing, etc., and achieve small amount of testing coal samples , Extensive practicability and short test period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] Its specific implementation is as follows:

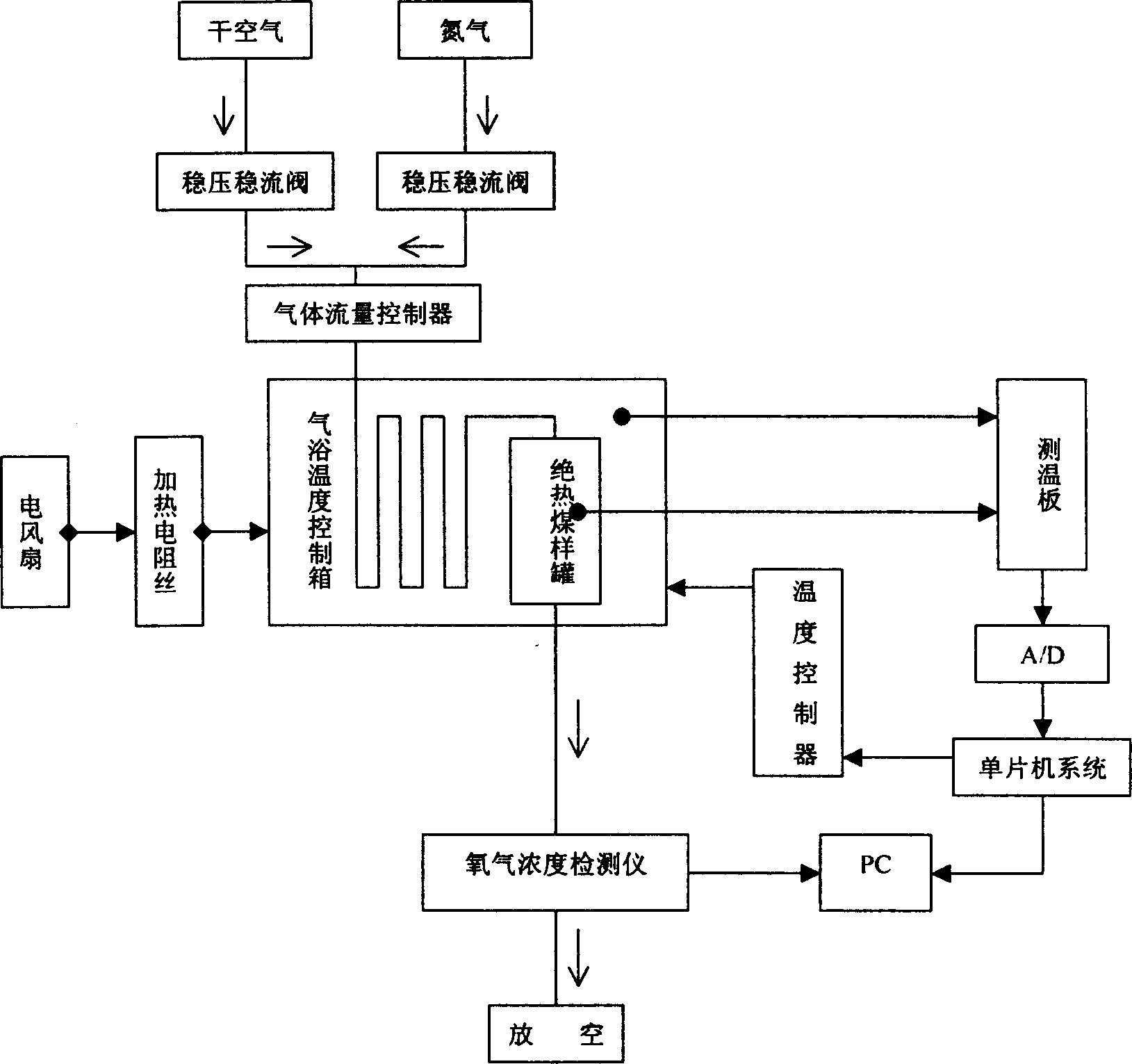

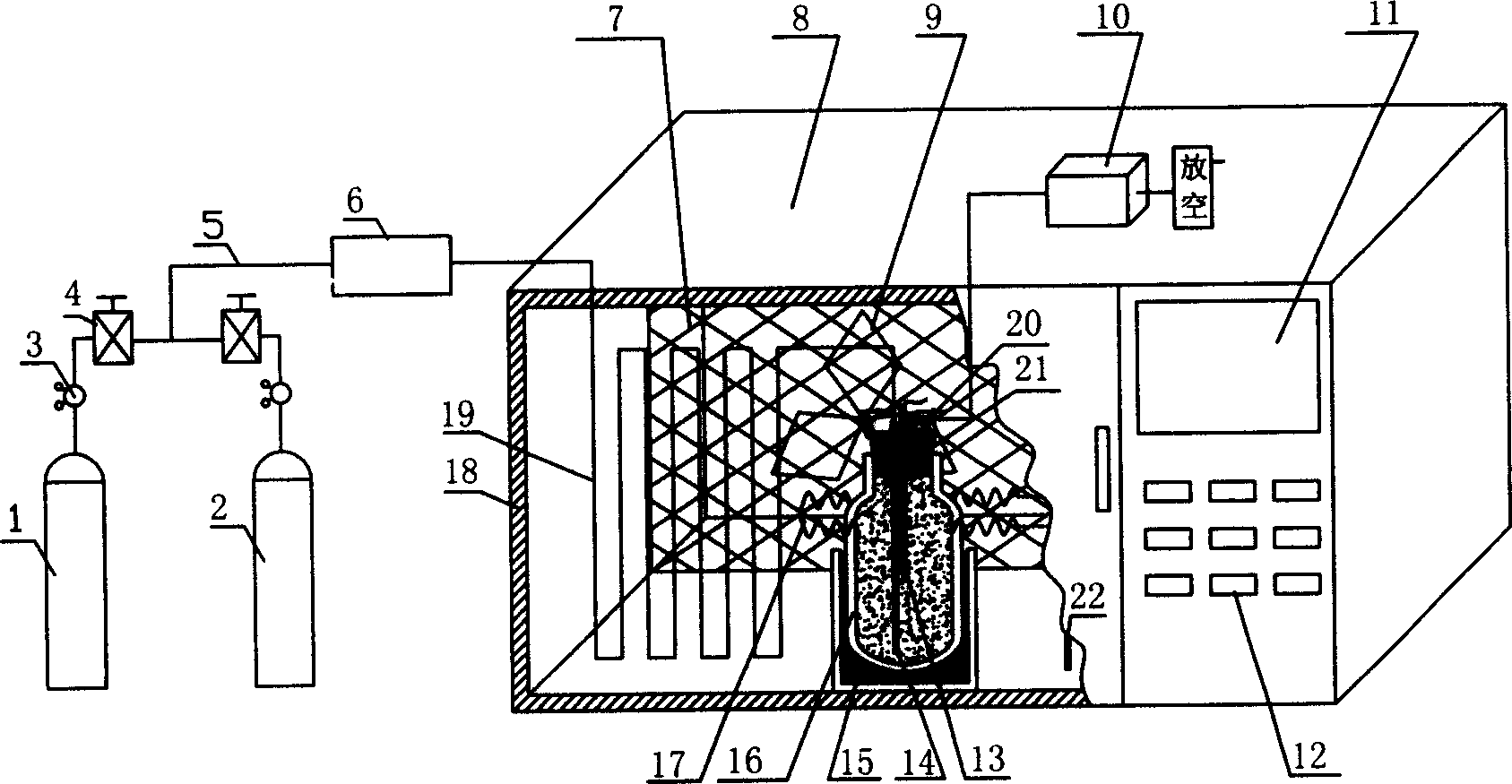

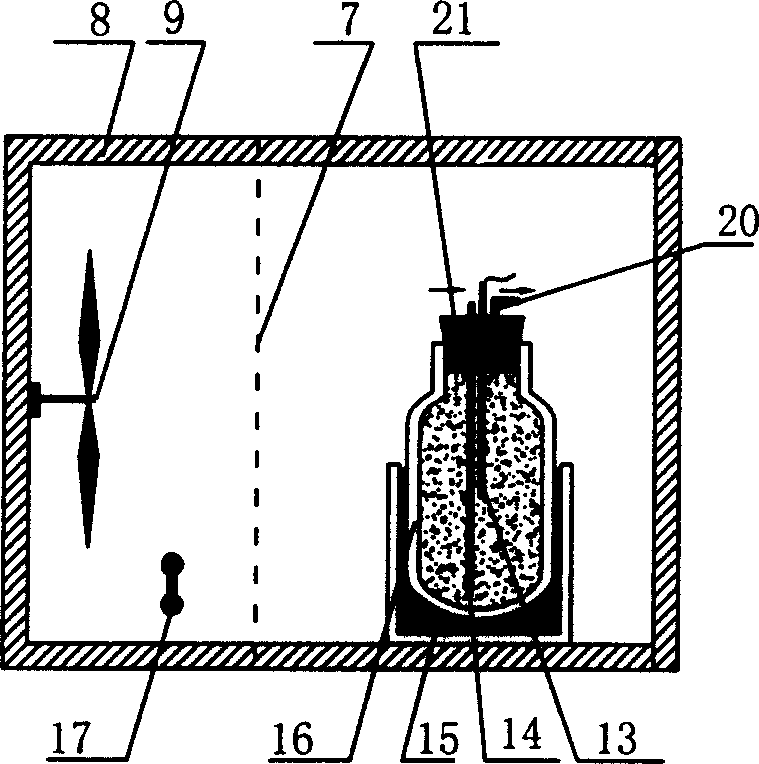

[0015] Preheating gas path system implementation mode: dry air or nitrogen enters the copper coil with a length of more than 15m coiled in the air bath temperature control box 8 after adjusting the flow rate through the decompression gauge 3, the pressure stabilization valve 4, and the gas flow controller 6. Air guide pipe 19, the other end of the copper air guide pipe 19 is connected with the air inlet pipe 14, the air inlet pipe 14 enters the bottom position of the insulated coal sample tank 16 through the tank plug 21 close to the center, and the outlet pipe 20 is located at the bottom of the coal sample tank 16. At the position between the upper surface and the bottom of the tank plug 21, the gas coming out of the gas outlet pipe 20 passes through the oxygen concentration monitor 10 to detect the oxygen concentration, and finally is emptied.

[0016] The implementation mode of the heat-insulated coal sample tank: the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com