Propellant powder variable capacity burning rate testing device

A test device and propellant technology, applied in ammunition testing, ammunition, weapon accessories, etc., can solve problems such as unseen propellant and inconsistent combustion conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

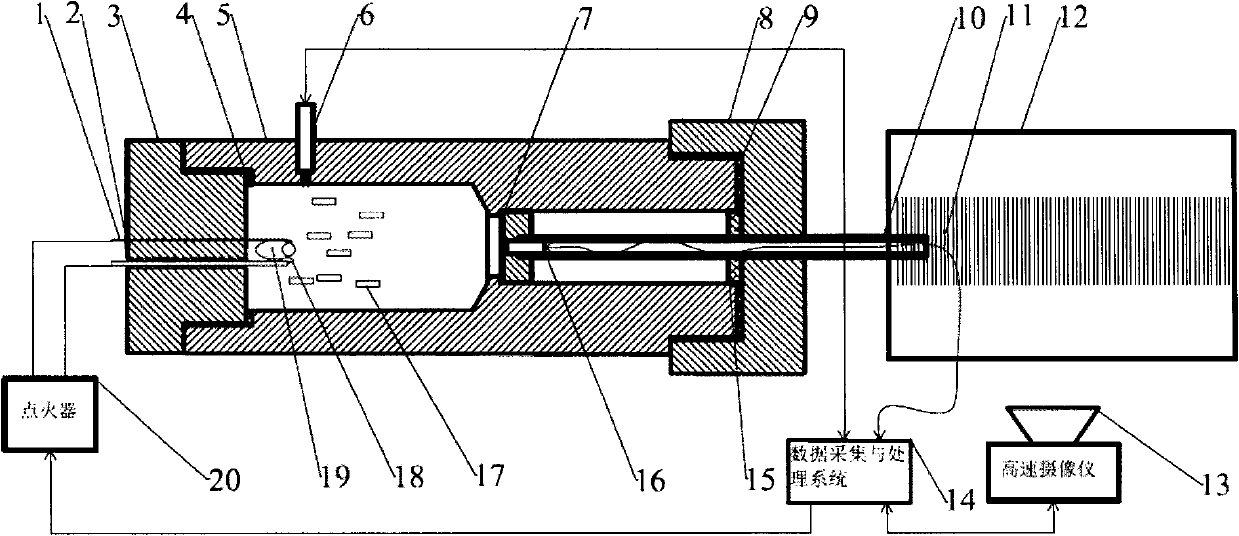

[0015] as figure 1 As shown, the preferred embodiment of the propellant variable volume burning rate test device includes a body assembly, an ignition assembly, a high-speed camera assembly, first and second pressure sensors 6, 16 and a data acquisition and processing system 14. The first and second pressure sensors 6 and 16 are standard products, and their model is KISTLER6213B.

[0016] The body assembly includes a body 5 , a first sealing plug 3 , a second sealing plug 8 , a buffer pad 15 , a piston rod 10 , a first gasket 4 , a second gasket 9 and a piston 7 . Body 5 has multi-stage through holes, from its left end to right end (referring to figure 2 ) are screw holes 5-1, large-diameter holes 5-3 and small-diameter holes 5-5 in turn: the size of the large-diameter hole 5-3 is Φ45mm×150mm and the first mounting hole 5 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com