Method for testing multi-target line quasi dynamic combustion performance of solid propellant

A technology of solid propellant and combustion performance, applied in fuel testing, material inspection, etc., can solve problems such as long testing cycle, and achieve the effect of reducing cost and shortening development and production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

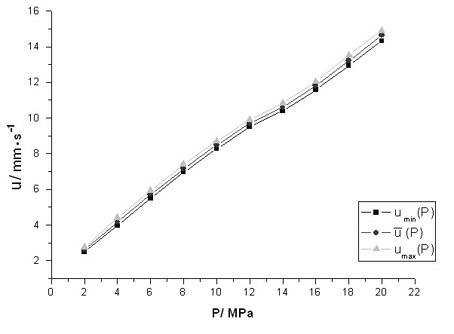

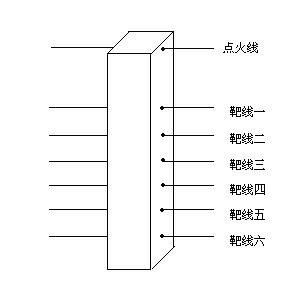

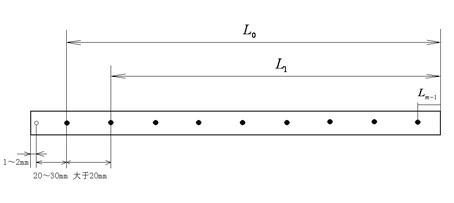

[0027] Cut the solid propellant to be tested according to the requirements in GJB 770B-2005 method 706.1, perform operations such as cutting, coating, drilling, threading, etc., and then use the target line method to test the propellant under various pressures from low pressure to high pressure (2-22MPa). static burning rate. Carry out at least 5 tests under each pressure, and calculate the average burning rate under the pressure after eliminating outliers by Grubbs' rule , the relationship between static average burning rate and pressure is obtained by polynomial fitting ,Right now —P curve.

[0028] Record the maximum effective value of the single ignition velocity test at each pressure and minimum rms , the relationship between the maximum effective value of the burning rate and the pressure was obtained by polynomial fitting and , combine them with The relationship curves are placed in the same coordinate system to form a family of curves (such as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com