Manufacturing method of high-strength parts thermoforming stamping die

A technology of stamping die and manufacturing method, which is applied in the field of hot forming stamping die manufacturing of high-strength parts, can solve the problems of different heat source transfer efficiency in simulation analysis, uneven material of mold forming blocks, inconsistent local expansion amount, etc., so as to shorten the design cycle. , the effect of shortening the development and production cycle and simplifying the development difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

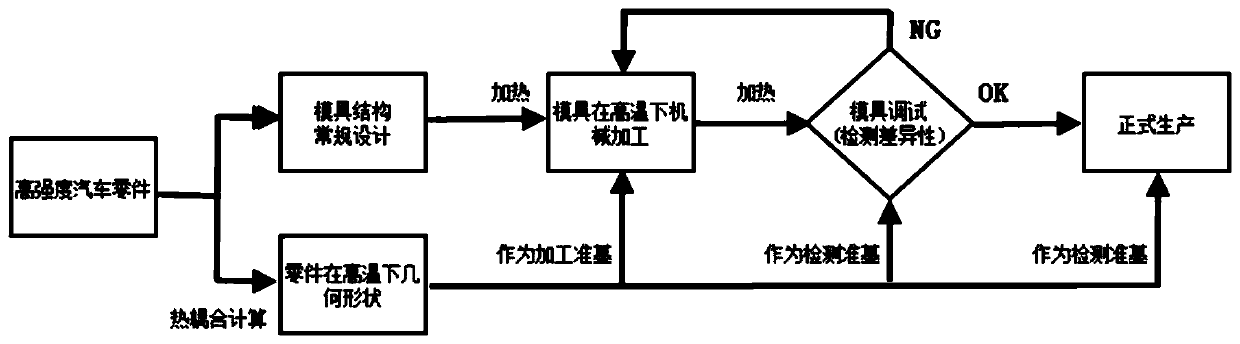

[0014] refer to figure 1 As shown, this embodiment is a method for manufacturing a high-strength part thermoforming stamping die, including the following steps:

[0015] S1, carry out conventional mold structure design as required, the mold is a mold for manufacturing a high-strength boron steel auto parts; at the same time, perform thermal coupling calculation according to the geometry of the parts at high temperature.

[0016] S2, the mold forming block is mechanically processed at a constant high temperature; the thermal coupling calculation data is used as the processing benchmark.

[0017] S3, inspect and debug the mold, compare the difference between the mold surface at high temperature and the design drawing; use the thermal coupling calculation data as the detection standard.

[0018] S4, the debugged mold enters formal production, and the thermal coupling calculation data is used as the production benchmark.

[0019] When applying this embodiment, the mold is heated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com