Method for preparing sulfuric acid by iron pyrite

A technology of pyrite and sulfuric acid, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of incomplete purification of furnace gas, difficult management and control, low sulfur burn-out rate, etc., and achieve the suppression of sulfuric acid mist particles Formation, improve product quality, improve the effect of burning out rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

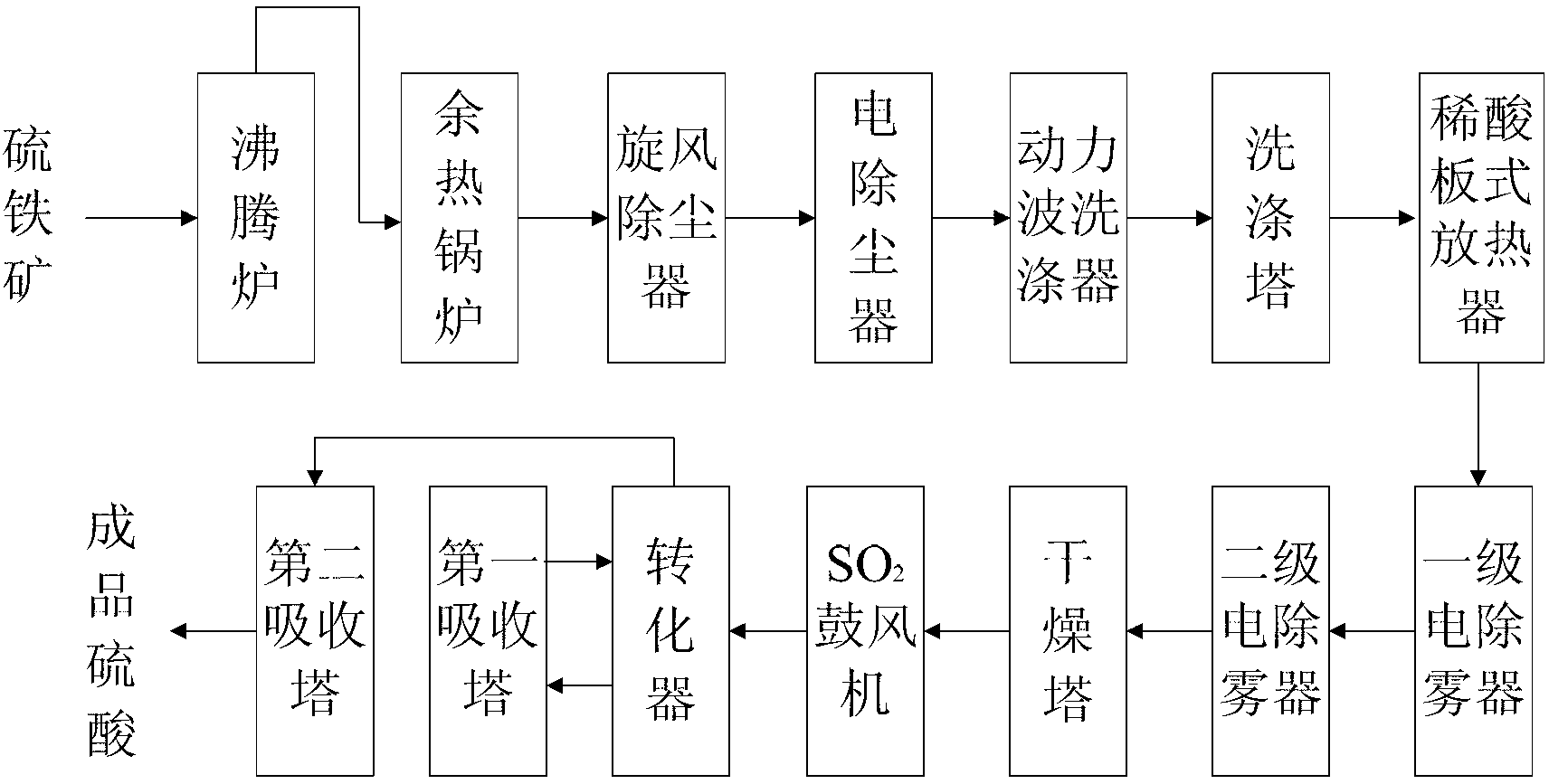

[0052] Send the pyrite with 48% sulfur content and 10% water content continuously and evenly to the fluidized fluidized furnace through the belt feeder, use the air blower to introduce air into the fluidized fluidized furnace, and control the oxygen content at the outlet of the fluidized fluidized furnace through the oxygen meter installed at the waste heat boiler According to the oxygen content, the amount of ore added to the fluidized fluidized furnace is adjusted, the oxidation roasting temperature is 850 ° C, and the pressure is 10 mm H 2 O, roasting for 15 minutes, the slag after oxidation and roasting is discharged from the overflow port of the fluidized fluidized furnace, enters the submerged cooling drum to cool down and increase humidity, and then is transported to the slag yard by a belt conveyor. SO in the outlet furnace gas 2 The volume fraction of the waste heat boiler is 13%. The generated furnace gas is passed through the waste heat boiler to reduce the temperat...

Embodiment 2

[0054] Send the pyrite with 48% sulfur content and 10% water content continuously and evenly to the fluidized fluidized furnace through the belt feeder, use the air blower to introduce air into the fluidized fluidized furnace, and control the oxygen content at the outlet of the fluidized fluidized furnace through the oxygen meter installed at the waste heat boiler , according to the oxygen content to adjust the amount of ore added to the fluidized furnace, the oxidation roasting temperature is 900 ° C, the pressure is 1mm H 2 O, roasting for 8 minutes, the slag after oxidation and roasting is discharged from the overflow port of the fluidized fluidized furnace, enters the submerged cooling drum to cool down and increase humidity, and then is transported to the slag yard by a belt conveyor. SO in the outlet furnace gas 2 The volume fraction of the waste heat boiler is 13%. The generated furnace gas is passed through the waste heat boiler to reduce the temperature of the furnace...

Embodiment 3

[0056] Send the pyrite with 48% sulfur content and 10% water content continuously and evenly to the fluidized fluidized furnace through the belt feeder, use the air blower to introduce air into the fluidized fluidized furnace, and control the oxygen content at the outlet of the fluidized fluidized furnace through the oxygen meter installed at the waste heat boiler According to the oxygen content, the amount of ore added to the fluidized fluidized furnace is adjusted, the oxidation roasting temperature is 920 ° C, and the pressure is 5 mm H 2 O, roasting for 10 minutes, the slag after oxidation and roasting is discharged from the overflow port of the fluidized fluidized furnace, enters the submerged cooling drum to cool down and increase humidity, and then is transported to the slag yard by a belt conveyor. SO in the outlet furnace gas 2 The volume fraction of the waste heat boiler is 13%. The generated furnace gas is passed through the waste heat boiler to reduce the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com