Full utilization method for middle and low-grade pyrite

A pyrite and low-grade technology, which is applied in the field of comprehensive utilization of medium and low-grade pyrite to produce acid, can solve the problems of tailings and mineral processing wastewater pollution, reduce equipment purchases and technological processes, save resources, and reduce economic burdens Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

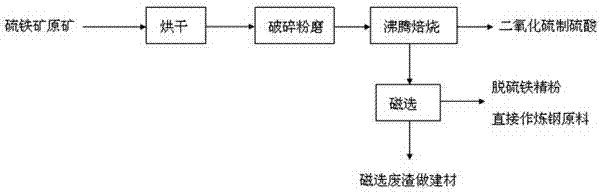

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: adopt the pyrite ore of Xuyong County, Luzhou City, Sichuan Province, the sulfur content of the raw ore is 15-18%, and the water content is below 3%. Put the raw ore directly into the ball mill, adjust the air volume of the fan, control the fineness of the ground ore powder to 50 mesh, and transport the ore powder to the finished product bin of the fluidized fluidized furnace. The ore powder in the silo is continuously conveyed into the fluidized fluidized furnace which is already in a burning state through a closed conveying mechanism, the furnace bottom pressure is controlled at 10-12KPa, the furnace temperature is 750-850°C, and the water color is controlled to be brownish black. The sulfur dioxide gas produced is sent to the subsequent section to produce sulfuric acid according to the conventional pyrite acid production process. The slag is collected from the lower slag outlet of fluidized fluidized furnace, boiler, cyclone dust collector and electrost...

Embodiment 2

[0015] Embodiment 2: adopt the pyrite ore of Xingwen County, Yibin City, Sichuan Province, the sulfur content of the raw ore is 15-18%, and the water content is about 5%. Firstly, the raw ore is dried until the moisture is 2%-3%, and the heat of drying comes from the waste heat generated from the production of sulfuric acid. Then put the dried raw ore into the ball mill, adjust the air volume of the fan, control the fineness of the ground mineral powder to 60 mesh, and transport the mineral powder to the finished product bin of the fluidized fluidized furnace. The ore powder in the silo is continuously conveyed into the fluidized fluidized furnace which is already in a burning state through a closed conveying mechanism, the furnace bottom pressure is controlled at 10-12KPa, the furnace temperature is 750-850°C, and the water color is controlled to be brownish black. The sulfur dioxide gas produced is sent to the subsequent section to produce sulfuric acid according to the conv...

Embodiment 3

[0016] Embodiment 3: adopt the pyrite of Dafang County, Guizhou Province, the sulfur content of the raw ore is 17-20%, and the water content is below 3%. Put the raw ore directly into the ball mill, adjust the air volume of the fan, control the fineness of the ground ore powder to 70 mesh, and transport the ore powder to the finished product bin of the fluidized fluidized furnace. The ore powder in the silo is continuously conveyed into the fluidized fluidized furnace which is already in a burning state through a closed conveying mechanism, the furnace bottom pressure is controlled at 10-12KPa, the furnace temperature is 750-850°C, and the water color is controlled to be brownish black. The sulfur dioxide gas produced is sent to the subsequent section to produce sulfuric acid according to the conventional pyrite acid production process. The slag is collected from the lower slag outlet of fluidized fluidized furnace, boiler, cyclone dust collector and electrostatic precipitator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com