Scroll compressor

A scroll compressor and moving scroll technology, applied in the field of scroll compressors, can solve problems such as poor effect and poor lubrication of moving scroll bearings, achieve obvious cooling effect, solve poor lubrication bearing burn, reduce burn The effect of the bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

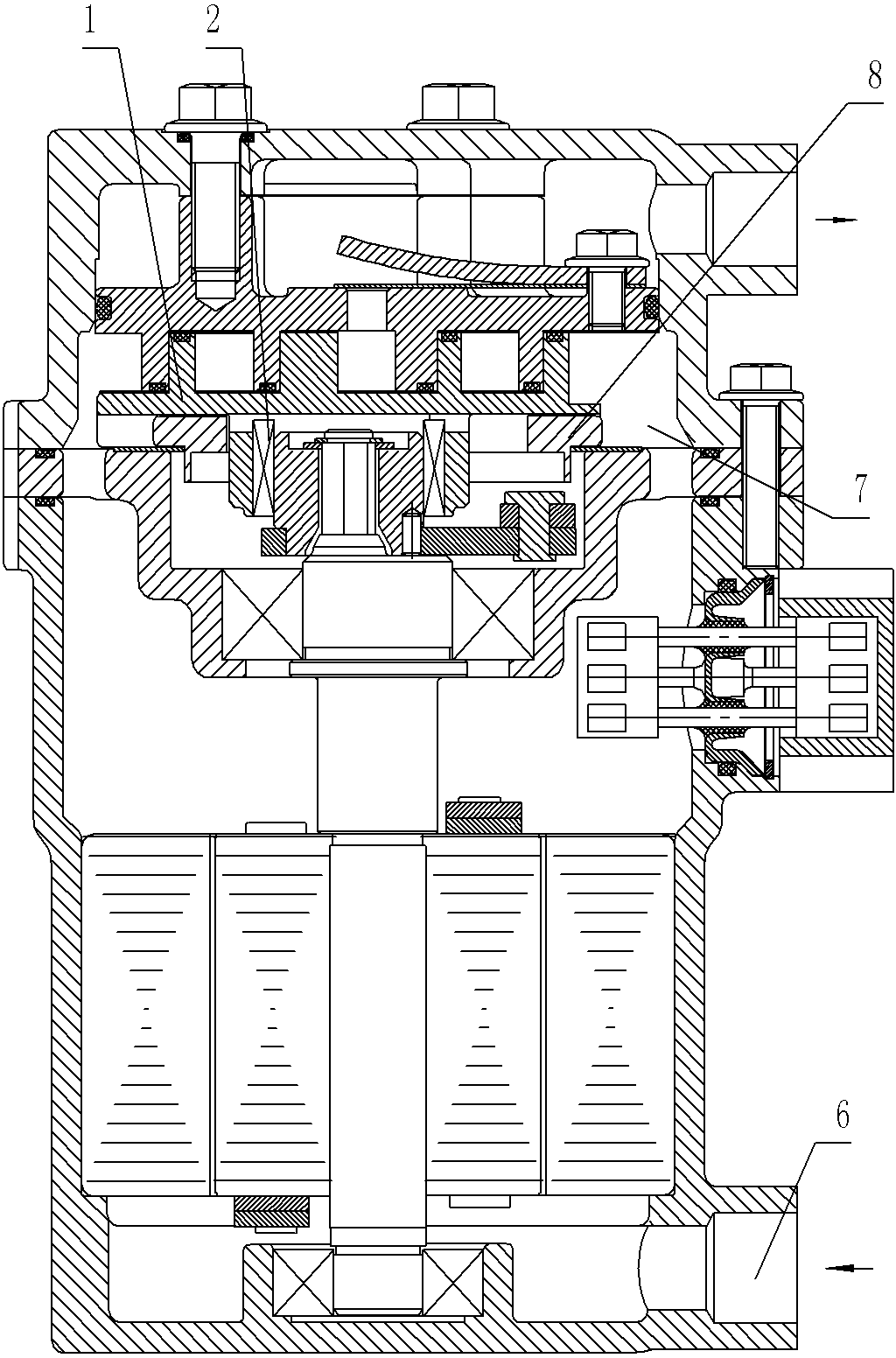

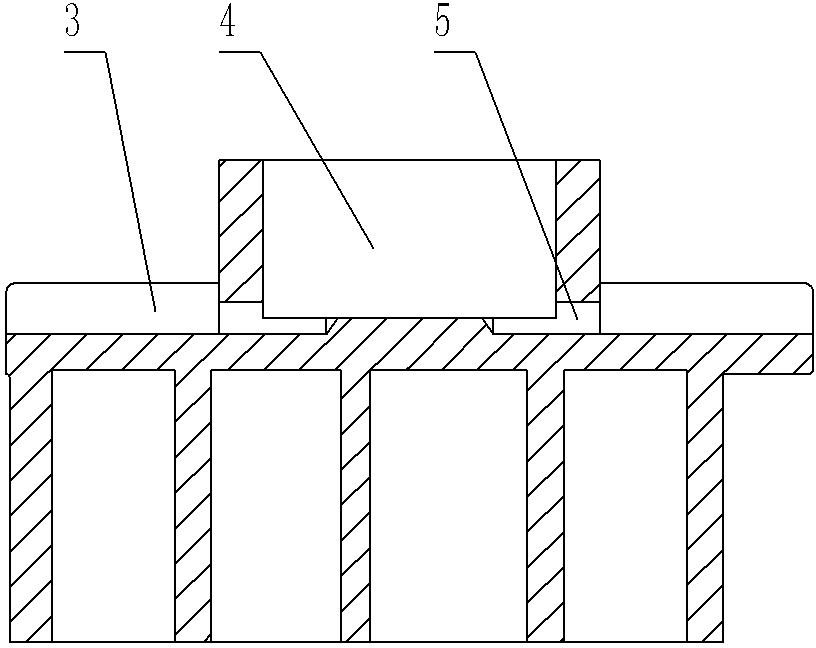

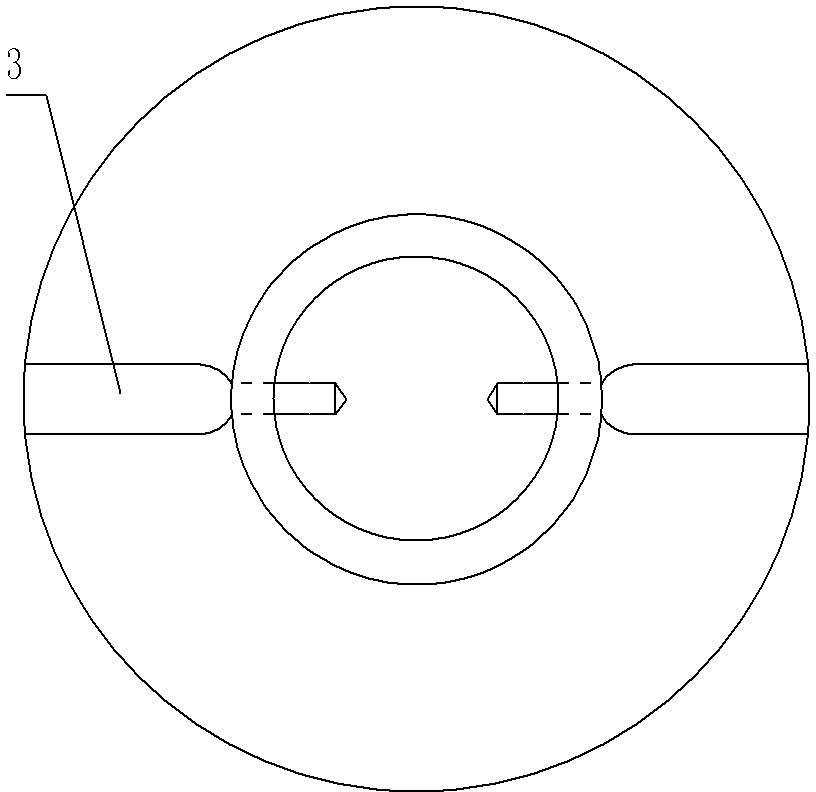

[0018] figure 1 The scroll compressor shown includes a movable scroll 1 and a bearing 2 installed in the bearing seat hole 4 on the back side of the movable scroll 1. The back end surface of the movable scroll 1 is provided with a slip ring outside the bearing seat part. Slot 3, as in figure 2 , image 3 As shown, the orbiting scroll 1 is provided with a channel 5 connecting the slip ring groove 3 and the bearing housing hole 4; the channel 5 is a circular hole axially parallel to the slip ring groove 3, and the diameter of the circular hole is preferably 3 to 8 mm, the diameter of the round hole of the passage 5 in this embodiment is 5.5 mm; there are two round holes of the passage 5, which are located on the side wall of the bearing seat hole 4, and respectively connected to the back end surface of the movable scroll 1 The two slip ring grooves 3 on the outside of the bearing housing part communicate.

Embodiment 2

[0020] figure 2 , image 3 As shown, the orbiting scroll 1 is provided with a channel 5 connecting the slip ring groove 3 and the bearing seat hole 4; the channel 5 is a circular hole axially parallel to the slip ring groove 3, and the diameter of the circular hole of the channel 5 is 3 mm; All the other features are the same as in Example 1.

Embodiment 3

[0022] figure 2 , image 3 As shown, the orbiting scroll 1 is provided with a channel 5 connecting the slip ring groove 3 and the bearing seat hole 4; the channel 5 is a circular hole axially parallel to the slip ring groove 3, and the diameter of the circular hole of the channel 5 is 8 mm; All the other features are the same as in Example 1.

[0023] When working, the refrigerant mixed with lubricating oil enters from the suction port 6 of the scroll compressor, enters the chamber 7 from the inner wall passage of the casing, and the slip ring 8 reciprocates in the slip ring groove 3 relative to the movable scroll 1, The refrigerant mixed with lubricating oil enters the bearing seat hole 4 from the channel 5 of the bearing seat hole 4 to lubricate and cool the bearing 6 installed therein, and then exits from the channel 5 on the other side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com