Laser cleaning head capable of rotating based on circular wedge-shape prism and using method

A laser cleaning and prism technology, applied in cleaning methods and utensils, chemical instruments and methods, optics, etc., can solve the problem of poor anti-interference ability of the galvanometer system, generating vibration and heat, increasing the burden on operators or mechanical clamping equipment, etc. It can improve the stability and anti-interference ability, reduce the size of the system, and reduce the difficulty of drive control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

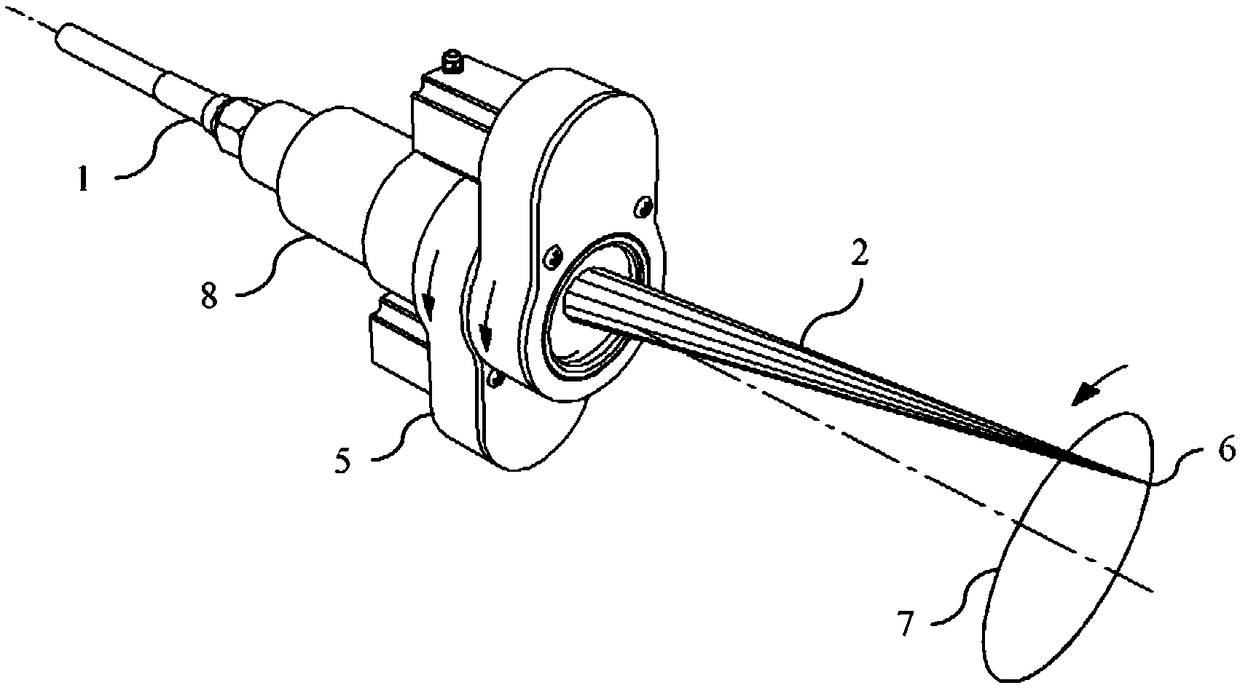

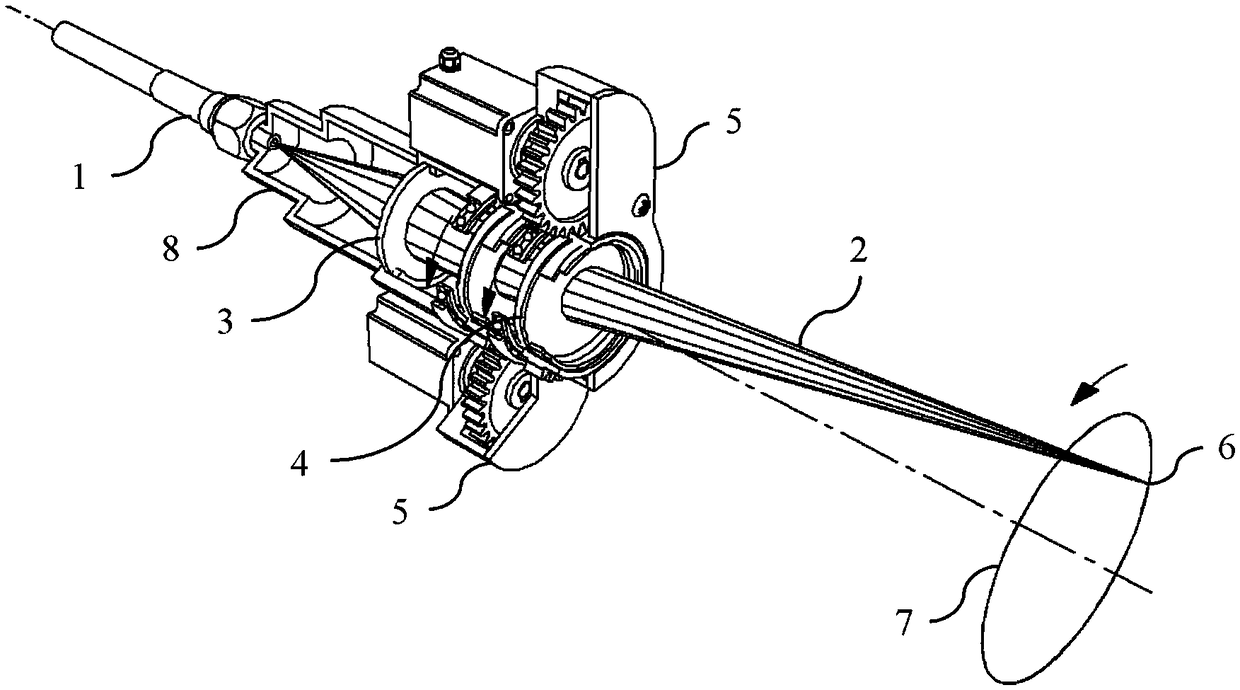

[0040] The laser cleaning head based on the rotation of the circular wedge prism of the present invention includes a housing fixedly connected to the optical fiber 1 connected to the external laser, a beam shaping component arranged in the housing and at least one circular wedge driven to rotate around the optical axis The prism 4, and the driving assembly for driving the circular wedge prism, the light exit point of the optical fiber, the beam shaping component and the circular wedge prism are arranged on the same optical axis and the corresponding intervals are arranged within a predetermined length.

[0041] Wherein, there are one, two or more than two circular wedge prisms, and the circular wedge prisms are individually driven by corresponding driving components 5 .

[0042] The present invention adopts a non-vibrating mirror scheme completely different from the prior art, and adopts one or more circular wedge-shaped prisms to rotate at a constant speed to deflect and displ...

Embodiment 2

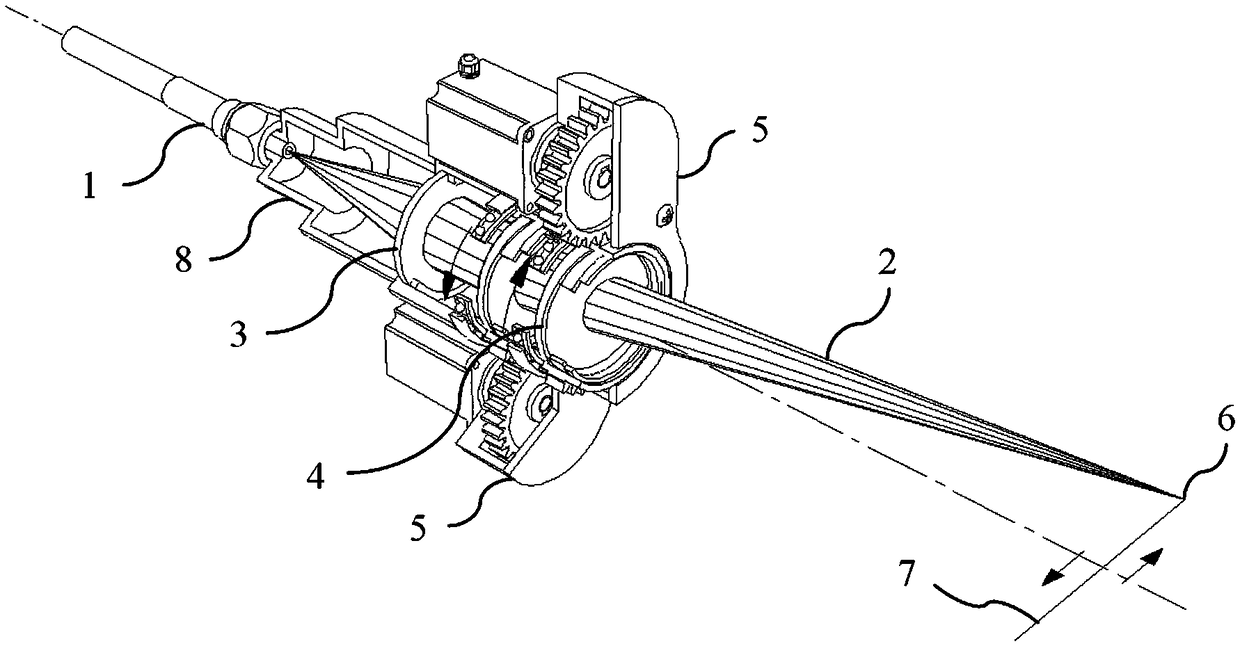

[0044] Specifically, the beam focusing component includes a focusing lens 31, and the focusing lens is fixedly arranged between the wedge prism component and the light exit point of the optical fiber and is coaxial. That is, the optical fiber 1 is installed at the end of the housing 8, and the focusing lens 31 is installed in the housing 8. The light beam 2 emitted by the optical fiber 1 is converged to the focal point 6 through the focusing lens 31, and the light beam 2 passes through one or more circular wedges. When the prism 4 is deflected, because the drive assembly 5 drives the circular wedge prism 4 to rotate, the deflection direction of the beam changes accordingly, and the trajectory of the final focus point 6 moves to form the trajectory line 7, which is the cleaning trajectory of the cleaning system .

[0045] The beam shaping assembly can also be in the form of a combination of collimating mirror 31 and flat field mirror 32, the one or more circular wedge prisms ar...

Embodiment 3

[0050] In the radiation environment, gamma rays seriously affect the service life of electronic components, so the galvanometer motor with feedback circuit and components is not suitable for use in the radiation environment. The drive motor described in the present invention is a common motor with one-way rotation and no chip, and a radiation-proof motor can be used. The surface of the bearing and the transmission mechanism is plated with molybdenum disulfide. That is, the surfaces of the bearing 53 , the driven wheel 54 and the driving wheel 56 are plated with molybdenum disulfide as a lubricant. Metals and lenses can withstand a large amount of radiation, but the feedback circuit and components of the vibrating mirror motor, common lubricants, and enameled wires of the motor will fail when exposed to radiation. The biggest advantage of the present invention is that the structure reduces the requirements of the motor. The motor is reduced to an ordinary motor, and the anti-ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com