Production method of nickel-based GH4080A alloy wire rod

A GH4080A, production method technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of high manufacturing difficulty, large manufacturing difficulty, small temperature range of material hot processing, etc., to reduce the amount of wear debris and processing costs, less input of raw material costs, and the effect of improving thermal processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

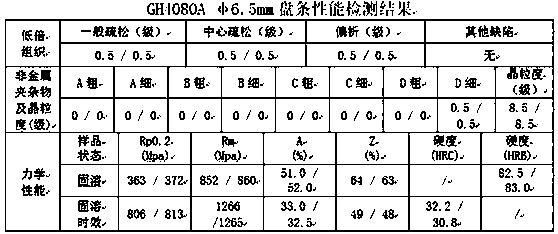

[0033] Example: Production of nickel-based GH4080A alloy φ6.5mm wire rod. Its technological process is: batching→vacuum induction smelting→electroslag remelting→heat treatment→forging blanking→bill grinding→heat treatment→rolling wire rod→online solid solution→finishing→inspection.

[0034] The specific content is as follows:

[0035] 1. Ingredients: The ingredients include recarburizer, metallic chromium raw materials, metallic nickel raw materials, metallic aluminum raw materials, metallic titanium raw materials, and ferroboron raw materials; it is known that the above raw materials will contain some Si, Mn, P, S, Cu , Fe, Co.

[0036] 2. Vacuum induction smelting: metal chromium and metal nickel are loaded into the furnace, carburant is added along with the furnace, and the refining temperature is controlled at 1510-1550 °C (the temperature also fluctuates during the tapping process, just keep within this range), and the refining time 60min; After refining, metal aluminum...

Embodiment 2

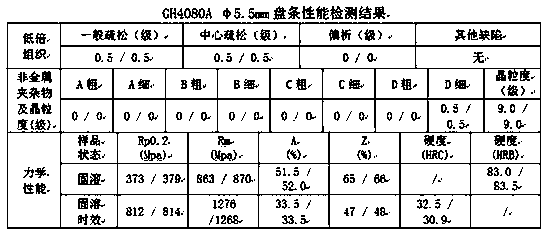

[0046] Example: Production of nickel-based GH4080A alloy φ5.5mm wire rod. Its technological process is: batching→vacuum induction smelting→electroslag remelting→heat treatment→forging blanking→bill grinding→heat treatment→rolling wire rod→online solid solution→finishing→inspection.

[0047] The specific content is as follows:

[0048] 1. Ingredients: Ingredients include recarburizer, metallic chromium raw materials, metallic nickel raw materials, metallic aluminum raw materials, metallic titanium raw materials, and ferroboron raw materials;

[0049] 2. Vacuum induction smelting: metal chromium and metal nickel are loaded into the furnace, carburant is added with the furnace, the refining temperature is 1510-1550 ℃, and the refining time is ≥60 minutes; after the refining is completed, metal aluminum and metal titanium are filled with Ar and ferric boron ; Sampling analysis and fine-tuning composition to adjust the main elements C, Cr, Al, Ti, B in place; then measure the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com