Smoke high-temperature dust removal and steam and coal gas recovery system and method for calcium carbide furnace

A high-temperature dust removal and recovery system technology, applied in the direction of furnaces, furnace components, and energy efficiency improvement, can solve the problems of filter bag burning or sticking bags, and achieve the effect of improving dust removal efficiency and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

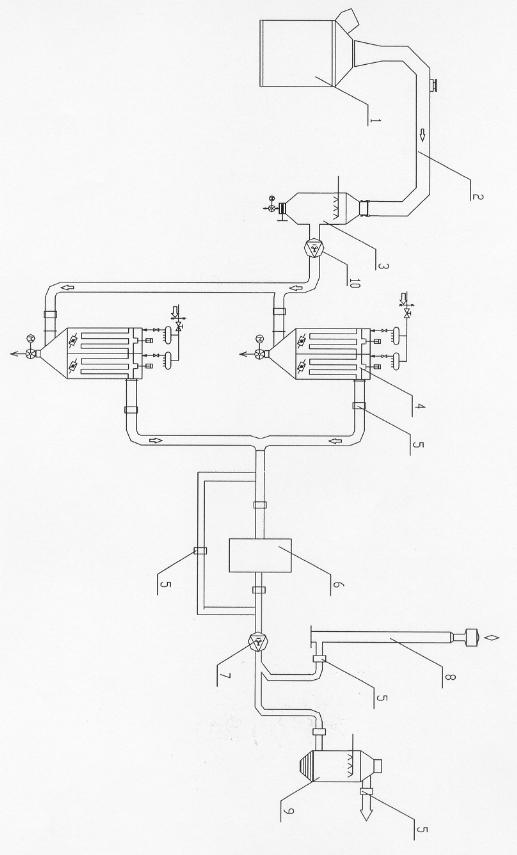

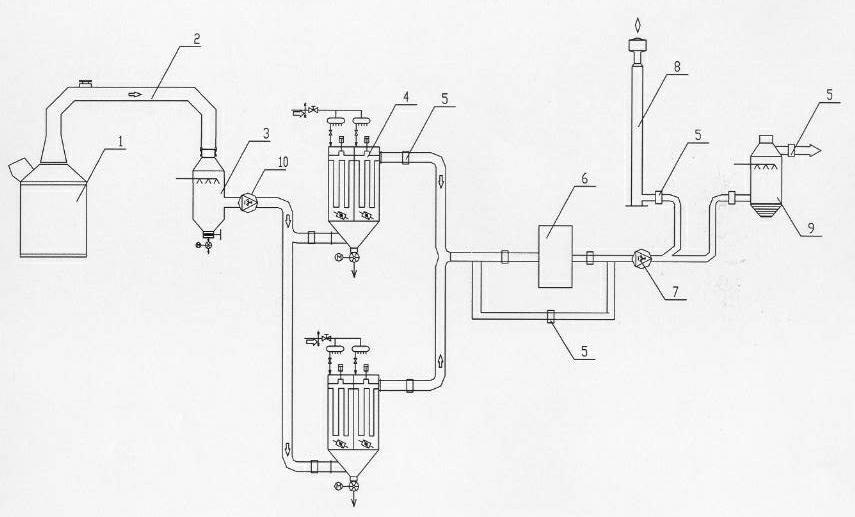

[0041] Such as figure 1 and figure 2 As shown, the present invention is suitable for high-temperature dedusting and recovery of steam and gas from submerged electric furnaces such as calcium carbide furnaces, and is also suitable for dedusting and recovery of metallurgical kiln gas and secondary recovery of steam. Main measures: set up water-cooled flue 2 or use evaporative cooling tower 3 for flue gas cooling, cool down the flue gas temperature of calcium carbide furnace 1 and control it at about 500°C; use high-temperature bag filter 4 for flue gas purification, and high-temperature bag dust removal The inlet of the filter 4 can be equipped with a high-temperature fan 10, which can keep the dust collector 4 and the waste heat boiler 6 in a positive pressure form; the outlet of the high-temperature bag filter 4 can be connected to the waste heat boiler 6 to recover steam; the waste heat boiler 6 can be installed for steam recovery; the waste heat boiler 6 The outlet is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com