Full premixed combustion smelting method and smelting furnace for producing glass using the method

A premixed and melting furnace technology, applied in glass furnace equipment, tank furnace, glass production, etc., can solve the problems of low quality of finished products, high cost of raw materials, low utilization rate of heat energy, etc., and achieve low production cost, fuel saving, Effect of production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

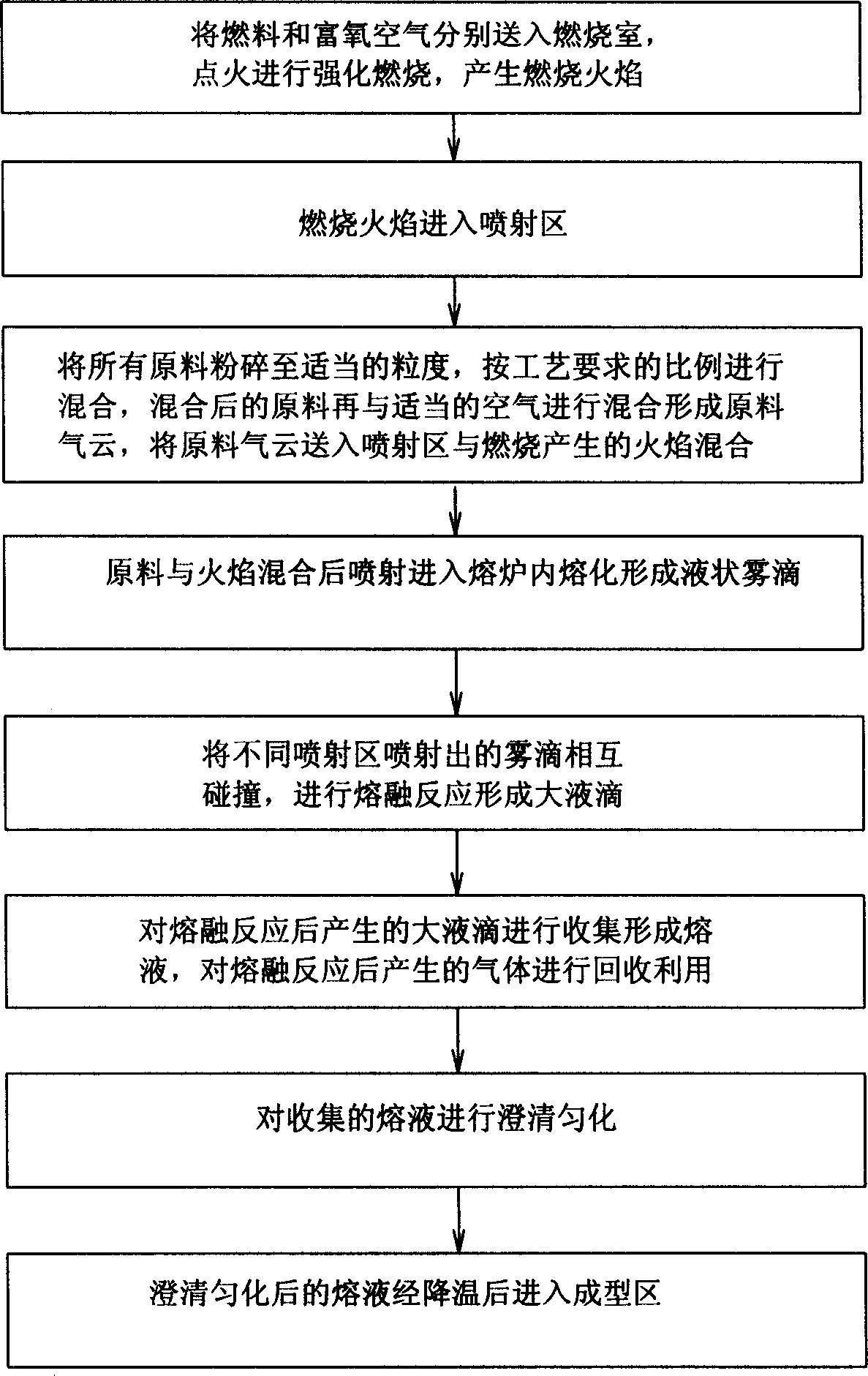

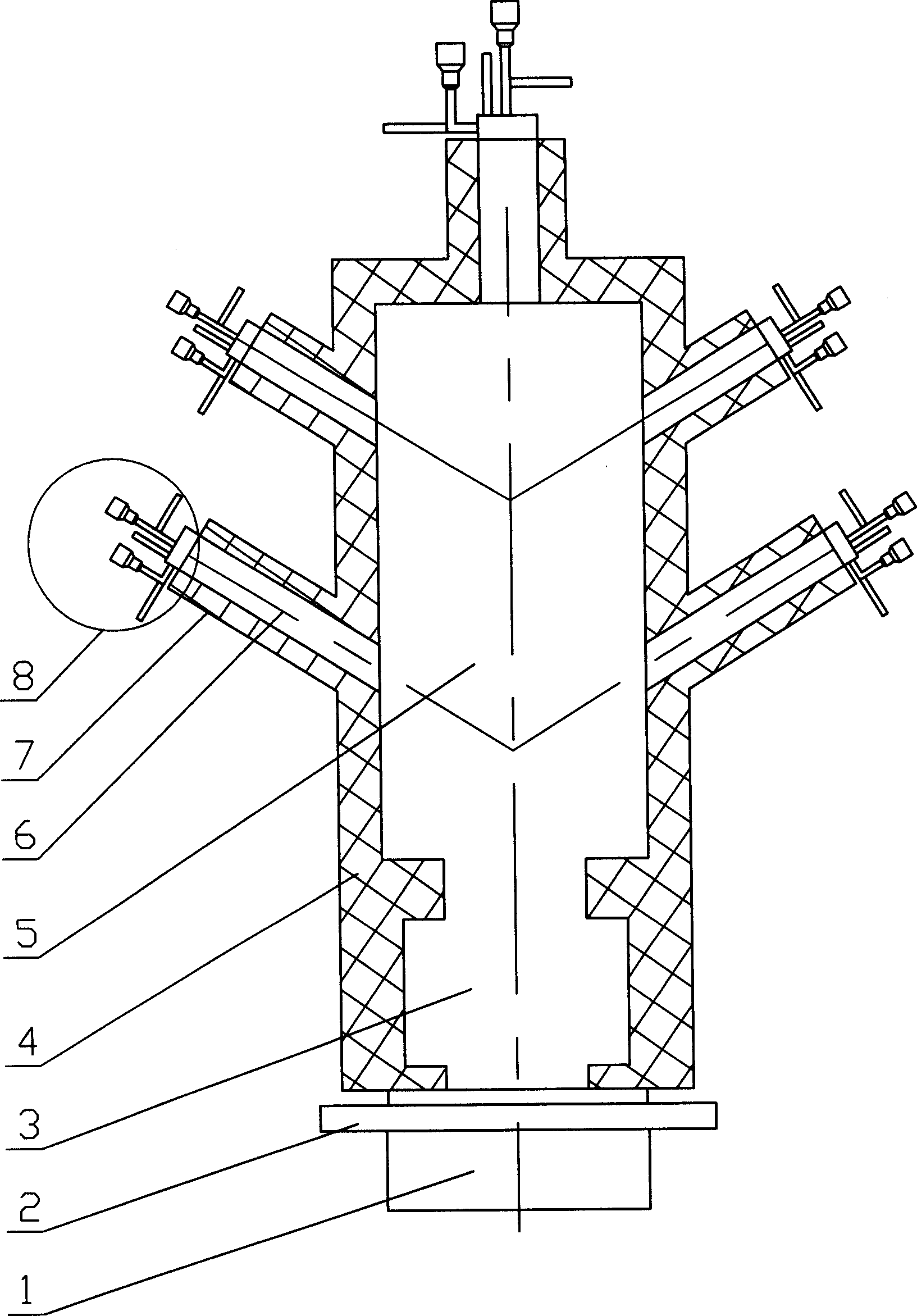

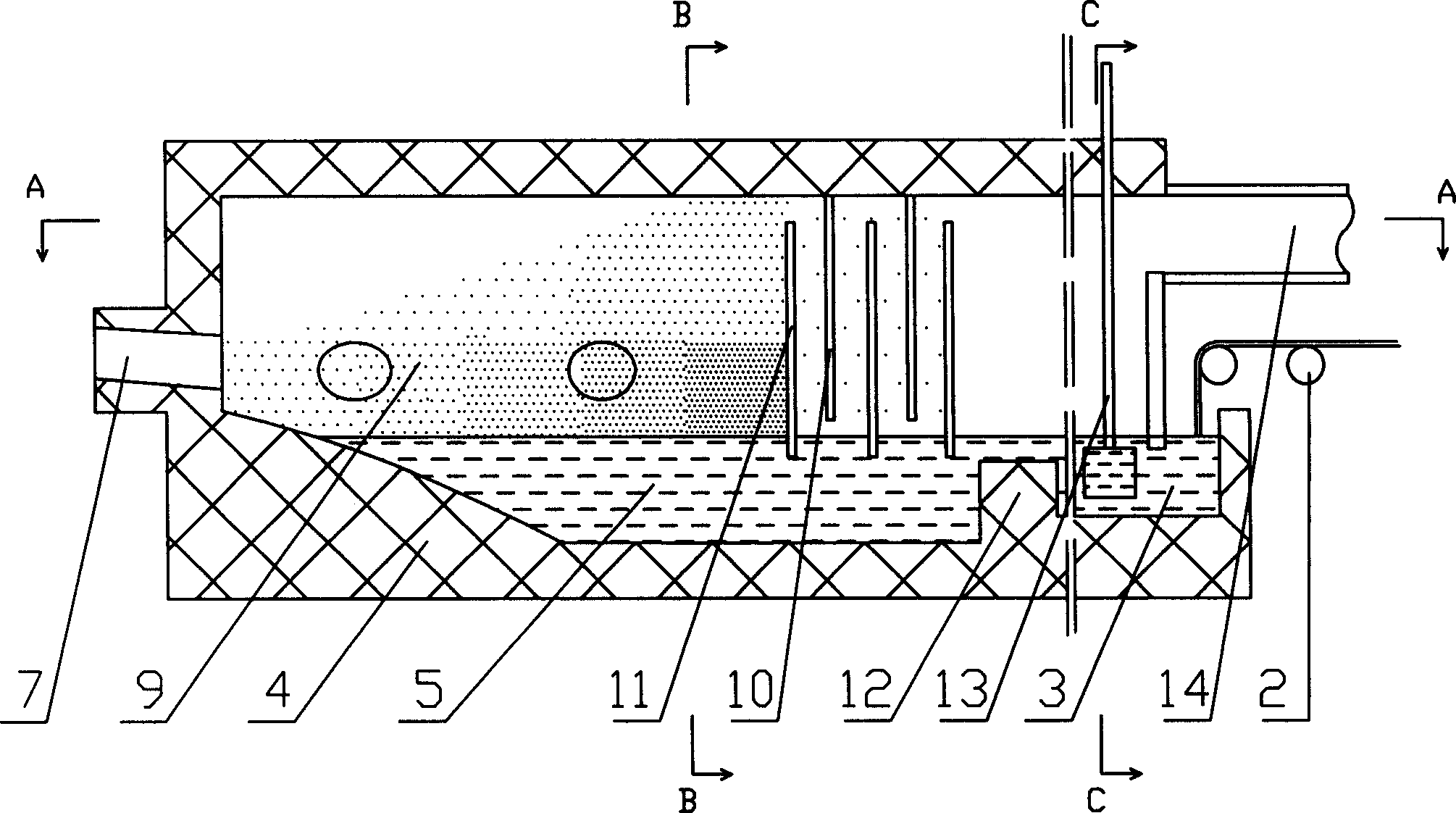

[0088] figure 1 It is a flowchart of the smelting combustion method of the present invention, figure 2 It is a schematic diagram of the furnace structure using the smelting and combustion method of the present invention. After the coal is crushed by the rod mill to meet the required particle size, it enters the pulverized coal bin, but the moisture content of the pulverized coal must be controlled to ensure unimpeded passage through the pressurized coal lock hopper device. The pulverized coal entering the furnace is transported from the pulverized coal bin to the pressurized coal lock hopper, and the pressure of the lock hopper fluctuates periodically between the atmospheric pressure and the working operating pressure. After the pulverized coal enters the pressurized coal lock hopper, it enters the fuel supplier 33 below through a valve. Under the action of gravity, the pulverized coal is sent to the fuel delivery pipe 30 communicating with the fuel supplier 33. The dense p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com