Nickel-based alloy electro slag remelting smelting method

A nickel-based alloy and electroslag remelting technology, which is applied in the field of electroslag remelting and smelting, can solve the problems of titanium element burning, uneven composition of molten ingot, low average recovery rate of titanium, etc., and achieves the effect of solving burning loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The method for electroslag remelting of the nickel-based alloy of the present embodiment is the following sequential steps:

[0022] Select the nickel-based alloy to make a steel billet with a thickness of 220mm, and the weight percentage of the nickel-based alloy composition is:

[0023] C: 0.009%, Si: 0.23%, Mn: 0.43%, P: 0.015%, S: 0.001%,

[0024] Al: 0.18%, Cr: 23.23%, Ni: 39.16%, Mo: 2.87%, Cu: 2.05%,

[0025] Ti: 0.83%, the rest is Fe and unavoidable impurities.

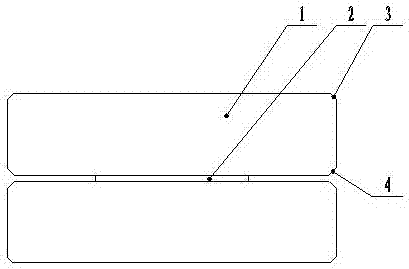

[0026] Cut the steel billet into two nickel-based alloy billets with a length of 2210mm, a width of 220mm, and a height of 220mm. , the inner chamfer 4 is the opposite chamfer of two nickel-based alloy billets 1, the length of both sides is 15mm), and the surface of the electrode is polished, with a roughness Ra of 4.35 μm.

[0027] Process the titanium plate into a titanium plate 2 with a width of 100 mm, a length of 300 mm and a thickness of 1.0 mm, add it between two nickel-based alloy bill...

Embodiment 2

[0031] The method for electroslag remelting of the nickel-based alloy of the present embodiment is the following sequential steps:

[0032] Select the nickel-based alloy to make a steel billet with a thickness of 220mm, and the weight percentage of the nickel-based alloy composition is:

[0033] C: 0.010%, Si: 0.25%, Mn: 0.38%, P: 0.010%, S: 0.001%,

[0034] Al: 0.20%, Cr: 23.12%, Ni: 40.23%, Mo: 2.96%, Cu: 2.25%,

[0035] Ti: 0.87%, the rest is Fe and unavoidable impurities.

[0036] Cut the steel billet into two nickel-based alloy steel billets with a length of 2210mm, a width of 110mm, and a height of 220mm. , the inner chamfer 4 is the opposite chamfer of two nickel-based alloy billets 1, the length of both sides is 15mm), and the surface of the electrode is polished, with a roughness Ra of 5.21 μm.

[0037] Process the titanium plate into a titanium plate 2 with a width of 40 mm, a length of 300 mm and a thickness of 1.0 mm, add it between two nickel-based alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com