Intelligent control household garbage pyrolysis gasifier

A technology of pyrolysis gasification and domestic waste, applied in the field of resource utilization of domestic waste, can solve the problems such as the inability to adjust the ventilation material layer, and achieve the effects of convenient control, uniform air supply, and solution to burning deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be more clearly and completely described below through the embodiments and in conjunction with the accompanying drawings.

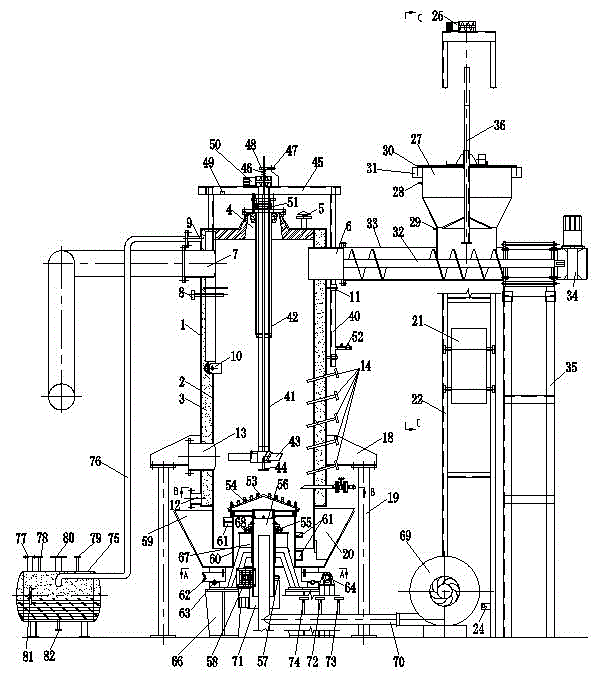

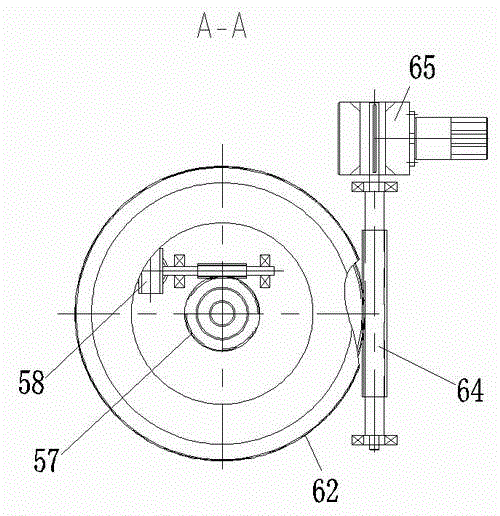

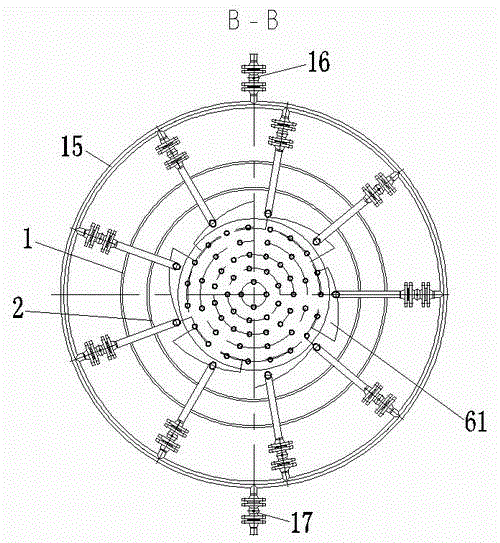

[0015] figure 1 , 2 , 3, and 4 show a structural diagram of an intelligently controlled domestic waste pyrolysis gasifier. Among the figure, the intelligent control household waste pyrolysis gasification furnace includes a furnace body, an ash tray 59, an air supply system, a feeder, a distributor, a rotary furnace drive mechanism and an ash tray drive mechanism. The outer casing 1 and the inner casing 2 form a watertight water jacket 3, and the body of heater is fixed on a body of heater fixing frame 18 supported by a support column 19, and an ash tray 59 is provided at the bottom of the body of heater.

[0016] The feeder includes a screw feeding bin 27 and a lifting bucket 21. The screw feeding bin 27 on the support frame 35 is fixedly connected to the feeding pipe 6 on the furnace body through a screw outer cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com