Method for desilicating molten iron by stirring

A molten iron desiliconization technology, applied in the field of stirring desiliconization of molten iron, molten iron desiliconization and refining of casting pig iron, can solve the problems of high consumption of refractory materials, environmental pollution, large equipment occupation, etc., and achieve the effect of reducing slag amount and desiliconization good, responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

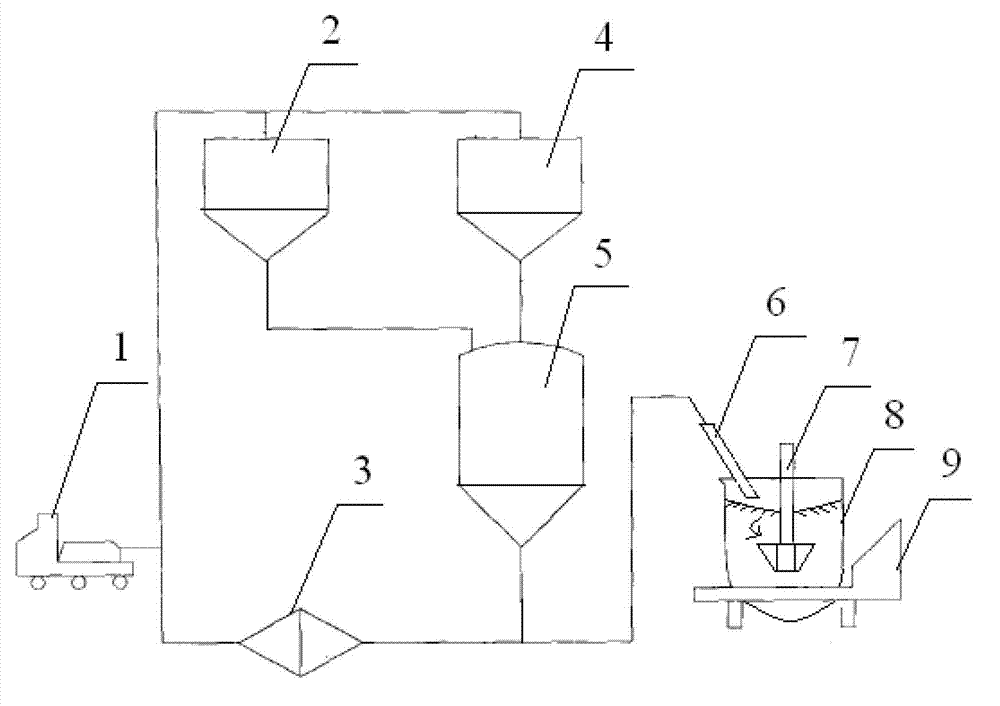

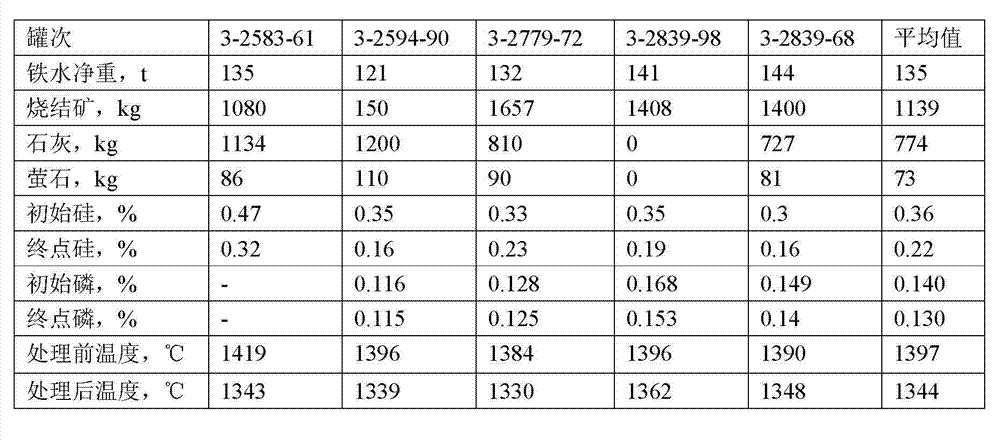

Embodiment 1

[0028] In this example, 5 tanks of desiliconization were carried out. The desiliconization route of molten iron sinter is: molten iron tank—a small amount of slag removal—lowering stirring paddle for stirring—feeding of sinter and mixture—stirring and desiliconization—lifting the paddle to stop stirring—slagging off. The inner height of the hot metal treatment tank is 4120mm, the mouth diameter is 3100mm, and the average clearance height of the hot metal tank is 1.25m. Sintered ore powder T.Fe>55%, the mixture is a mixture of lime and fluorite, the mixing mass ratio is 9:1, lime powder CaO>85%; fluorite powder CaF 2 >85%, see Table 1, Table 2 and Table 3. The raw material ratio and addition amount of the desiliconizing agent are shown in Table 4.

[0029] Table 1 Composition of sinter

[0030] Fe 2 o 3 / %

FeO / %

T.Fe / %

CaO / %

SiO 2 / %

67.3

6.0

55.4

10

4

[0031] Table 2 Composition of lime powder

[0032] ...

Embodiment 2

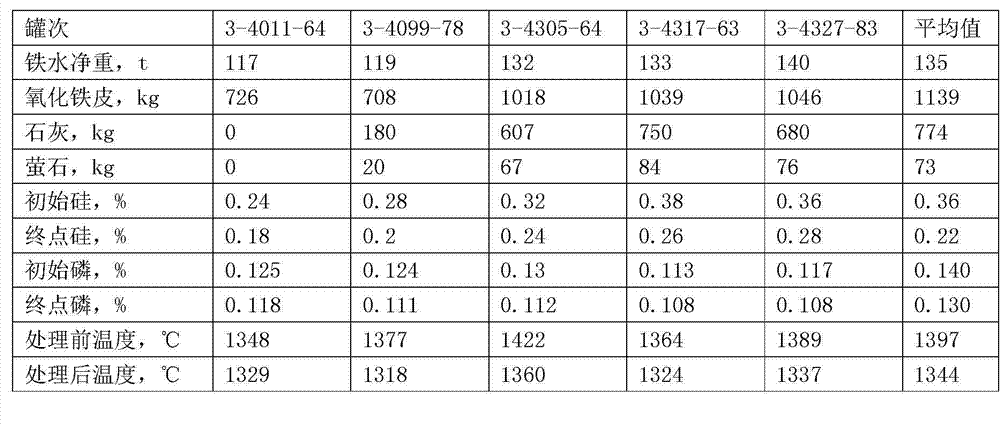

[0042] In this example, 5 tanks of desiliconization were carried out. The process route for desiliconization of molten iron oxide scale is: molten iron tank—a small amount of slag removal—adding oxide scale and mixture—stirring desiliconization——slagging off. The average clearance height of the hot metal tank is 1.3m. The T.Fe=72.03% of the iron oxide scale, the mixture is the mixed powder of lime and fluorite, and the composition is shown in Table 2 and Table 3. The raw material ratio and addition amount of the desiliconizing agent are shown in Table 6 and Table 7.

[0043] Table 6 Iron oxide scale composition

[0044] T.Fe / %

T.O / %

CaO / %

S / %

SiO 2 / %

72.03

30.87

1.07

0.025

0.91

[0045] Table 7 The relationship between the amount of desiliconization agent

[0046] Hot metal ΔSi / %

Rolled steel sheet / kg / t 铁

Mixture / kg / t 铁

0.1

4.6

1.7

0.15

6.9

2.5

0.2

9.2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com