Technology and device for co-producing ofproducing industrial monoammonium phosphate and co-producing high-quality monoammonium phosphate by utilizing middle-grade and low-grade collophanite

A monoammonium phosphate production industry technology, applied in the direction of phosphate, phosphorus oxyacids, etc., can solve the problems of the sustainable and healthy development of the phosphorus chemical industry, difficulties in the utilization of medium and low-grade phosphate rocks, and poor production stability. Desulfurization and sedimentation effect, reduction of SO3 index and impurity content, and effect of reducing desulfurization cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

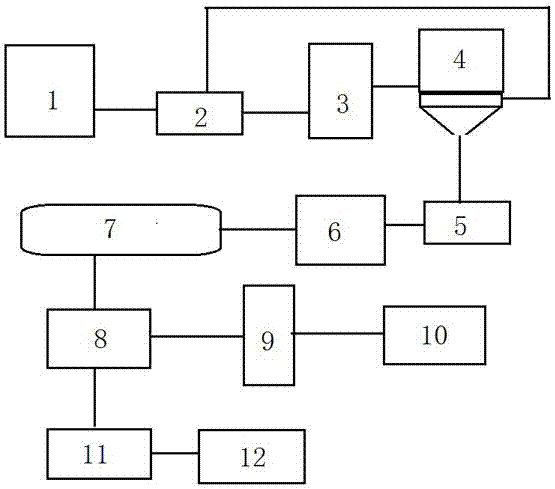

Image

Examples

Embodiment 1

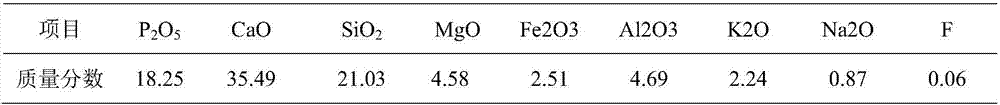

[0029] A process for producing industrial monoammonium phosphate co-producing high-quality monoammonium phosphate by utilizing medium and low-grade collophosphate rock, comprising the following steps:

[0030] 1) The raw ore is crushed, screened and roughly crushed to obtain raw ore with a particle size of less than 15mm, first deslimed, and then entered into the heavy medium cyclone for sorting, and the sorted heavy medium concentrate; The heavy medium concentrate is ball-milled until the particle size of the material is above 200 mesh, accounting for more than 83%, adding water to adjust the slurry concentration to 20-30wt%, adding reverse flotation reagents for sorting, including collectors, inhibitors (phosphoric acid) , pH regulator (sulfuric acid) foaming agent (n-butanol); Wherein concrete collector is sodium oleate, sodium lauryl sulfonate, cyclohexylamine, fatty acid polyoxyethylene ester by weight 45:25: 8:2 mixed, the addition amount is 1kg / t, and the temperature is...

Embodiment 2

[0034] A process for producing industrial monoammonium phosphate co-producing high-quality monoammonium phosphate by utilizing medium and low-grade collophosphate rock, comprising the following steps:

[0035] 1) The medium and low grade collophosphate ore is beneficiated by the heavy medium-double reverse flotation process, and the preparation is made with P 2 O 5 Phosphorus concentrate pulp with a mass fraction of more than 32%; the collectors used in double reverse flotation are sodium oleate, sodium dodecyl sulfonate, cyclohexylamine, fatty acid polyoxyethylene ester in a weight ratio of 40:20 :5:1 mixed.

[0036] 2) The phosphate concentrate pulp is extracted with sulfuric acid to obtain phosphoric acid pulp, the phosphoric acid pulp is subjected to high temperature vacuum filtration at 83-85 ° C and -0.06~-0.07MPa to obtain a phosphoric acid solution, and phosphate rock and barium carbonate are added for desulfurization. The weight ratio of ore to barium carbonate is 5...

Embodiment 3

[0039] A process for producing industrial monoammonium phosphate co-producing high-quality monoammonium phosphate by utilizing medium and low-grade collophosphate rock, comprising the following steps:

[0040] 1) The medium and low grade collophosphate ore is beneficiated by the heavy medium-double reverse flotation process, and the preparation is made with P 2 O 5 Phosphorus concentrate pulp with a mass fraction of more than 32%; the collectors used in double reverse flotation are sodium oleate, sodium dodecyl sulfonate, cyclohexylamine, fatty acid polyoxyethylene ester in a weight ratio of 50:30 :10:2 mixed.

[0041] 2) The phosphate concentrate pulp is extracted with sulfuric acid to obtain phosphoric acid pulp, the phosphoric acid pulp is subjected to high temperature vacuum filtration at 83-85 ° C and -0.06~-0.07MPa to obtain a phosphoric acid solution, and phosphate rock and barium carbonate are added for desulfurization. The weight ratio of ore to barium carbonate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com