Neutralization device and method for hydrochloric acid regeneration and desiliconization

A reaction device and reaction technology, which are used in chemical instruments and methods, chlorine/hydrogen chloride purification, water/sewage multi-stage treatment, etc., can solve the problem of unstable neutralization reaction of waste acid, low efficiency, and quality operation of desiliconization of acid regeneration system Instability and other problems, to achieve the effect of being conducive to recycling, ensuring efficiency, and improving mixing and reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

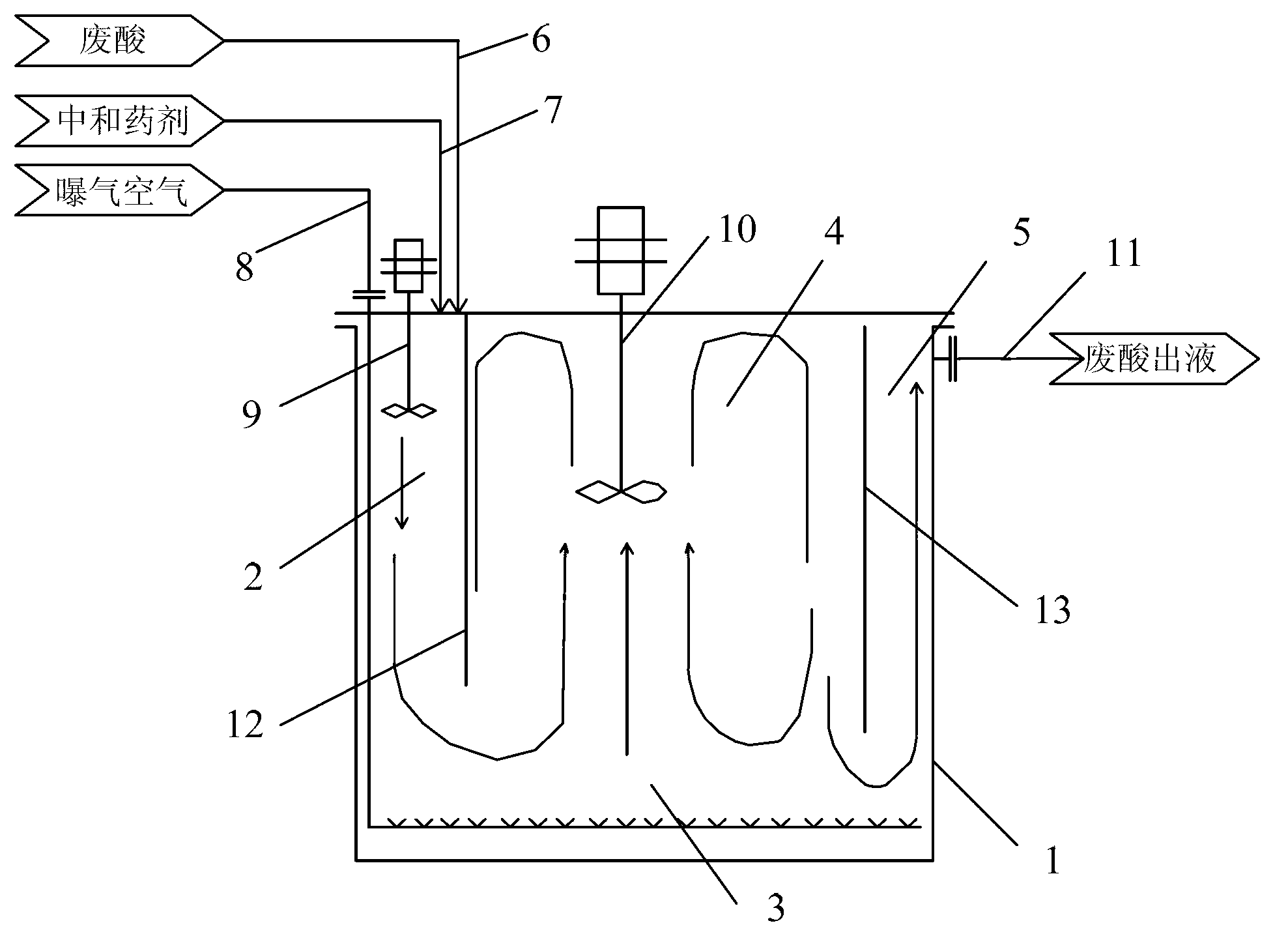

[0042] seefigure 1 , the present embodiment provides a hydrochloric acid regeneration desiliconization neutralization reaction device, including a neutralization reaction tank 1, and the inlet section of the neutralization reaction tank 1 is respectively connected with the waste acid supply pipe 6 and the neutralization agent supply pipe 7, The interior of the neutralization reaction tank 1 includes a premixing zone 2, an aeration mixing zone 3, a mechanical agitation mixing zone 4 and a liquid outlet anti-short flow tank 5, and the premixing zone 2 passes through the The inlet section is provided with a first partition 12, which is used for stirring and mixing the waste acid and the neutralizing agent, pre-mixing to form a reaction mixture solution, and the iron ions in the spent acid start to form oxyhydroxide during the reaction of the spent acid and the neutralizing agent. Iron precipitation; the liquid outlet anti-short flow tank 5 is formed by setting a second partition 1...

Embodiment 2

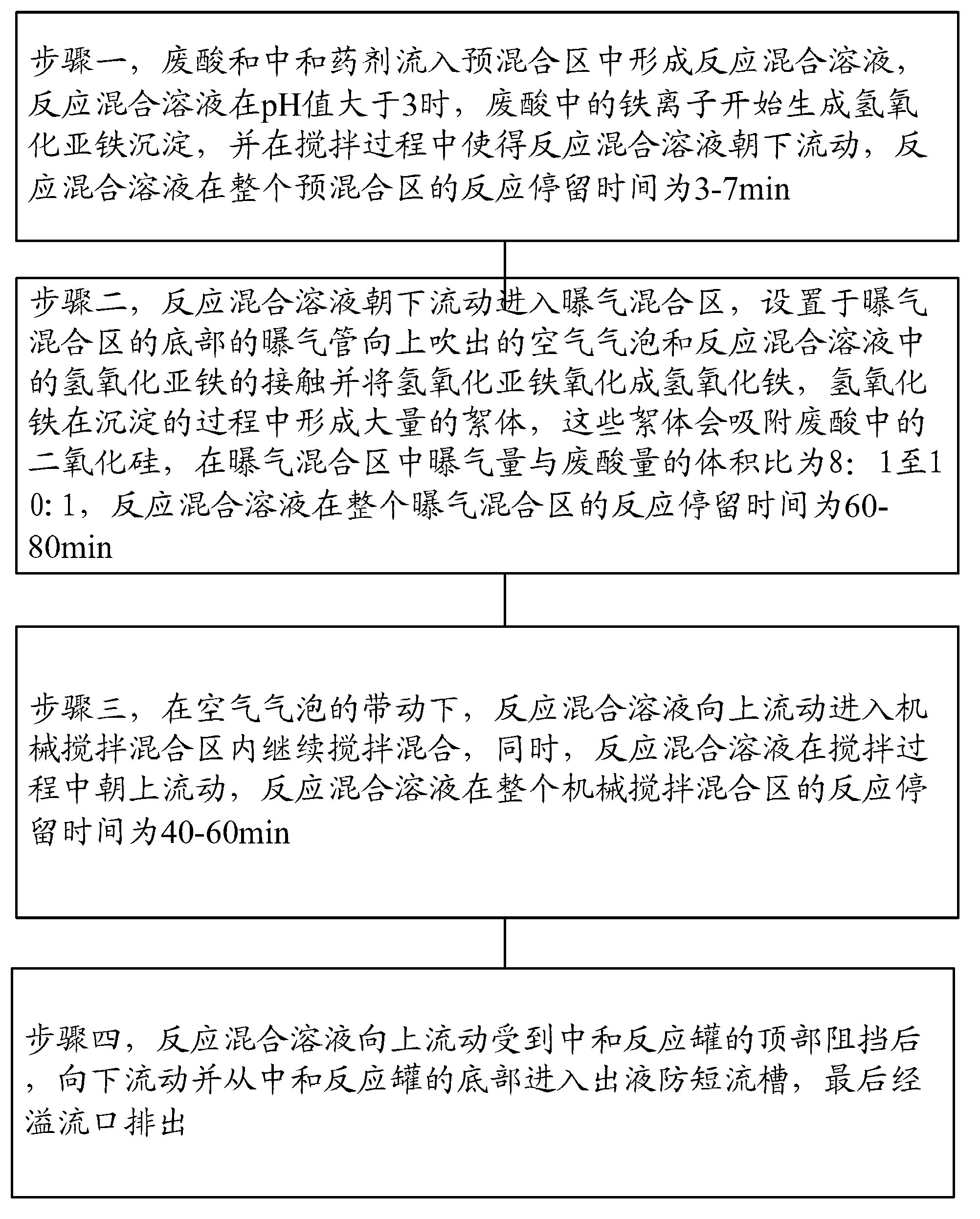

[0046] see figure 2 , and please combine figure 1 , the present embodiment provides a hydrochloric acid regeneration desiliconization neutralization reaction method, the hydrochloric acid regeneration desilication neutralization reaction device as described in Example 1 can be used, and the reaction method includes the following steps:

[0047] In step 1, the waste acid and neutralizing agent (such as ammonia water) flow into the premixing zone 2 to form a reaction mixture solution. When the pH value of the reaction mixture solution is greater than 3, the iron ions in the waste acid begin to form ferrous hydroxide precipitates (in and reaction), and make the reaction mixture solution flow downward during the stirring process, and the reaction residence time of the reaction mixture solution in the whole pre-mixing zone 2 is 3-7min.

[0048] Step 2, the reaction mixed solution flows downward into the aeration mixing zone 3, and the air bubbles blown upward by the aeration tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com