Patents

Literature

50 results about "Hydrochloric acid regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrochloric acid regeneration or HCl regeneration refers to a chemical process for the reclamation of bound and unbound HCl from metal chloride solutions such as hydrochloric acid.

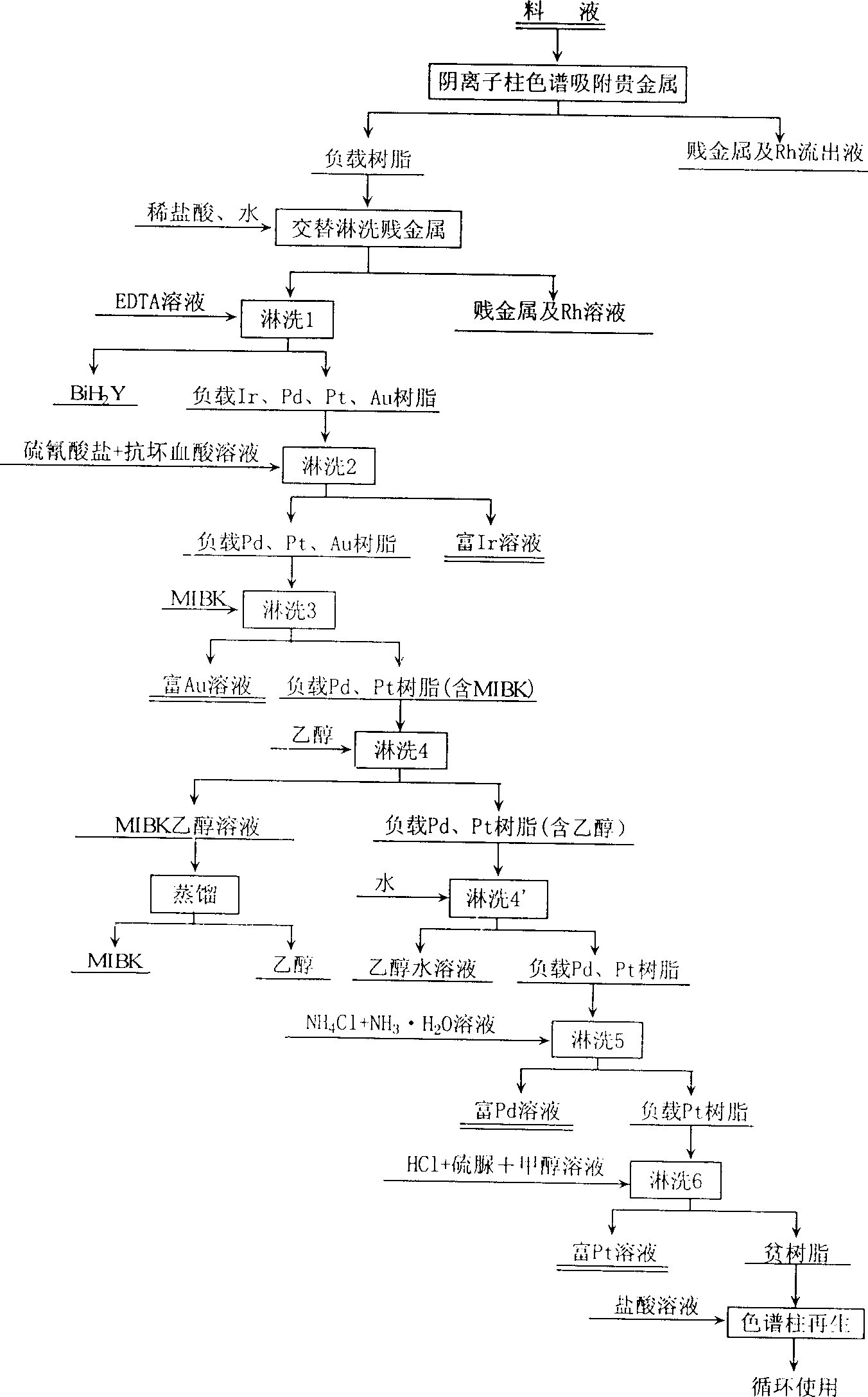

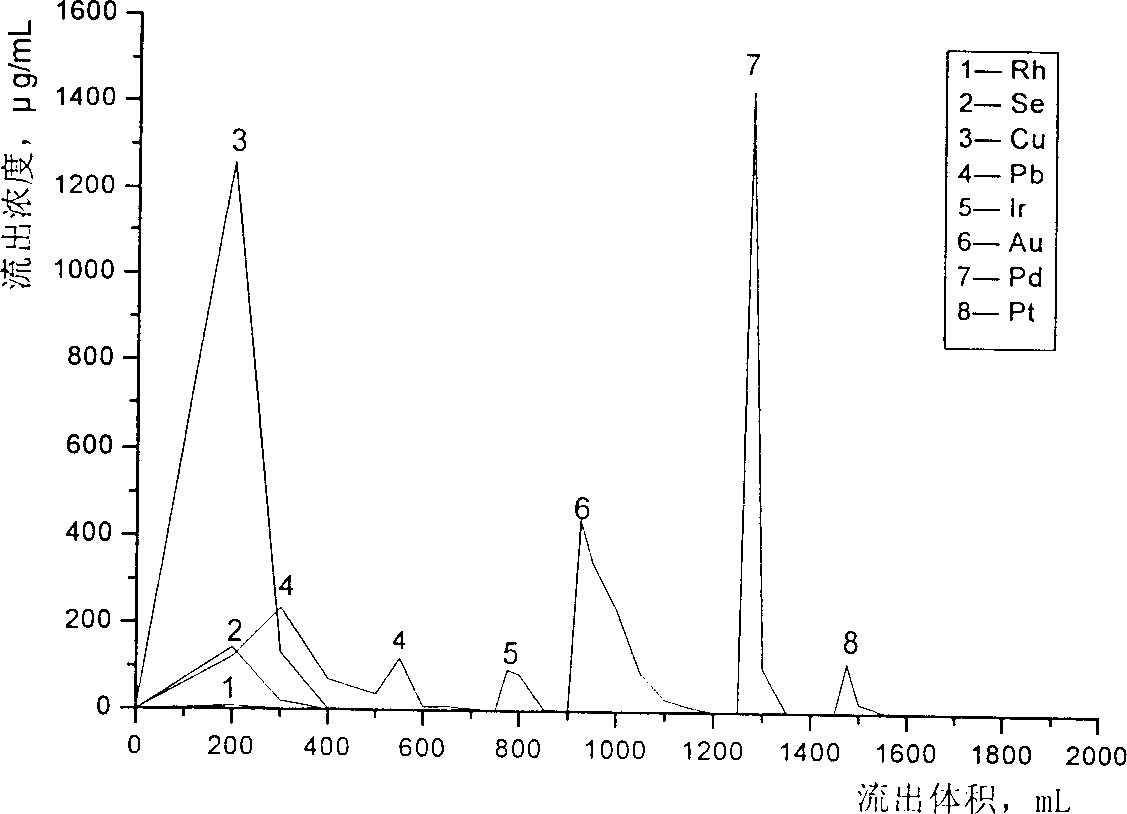

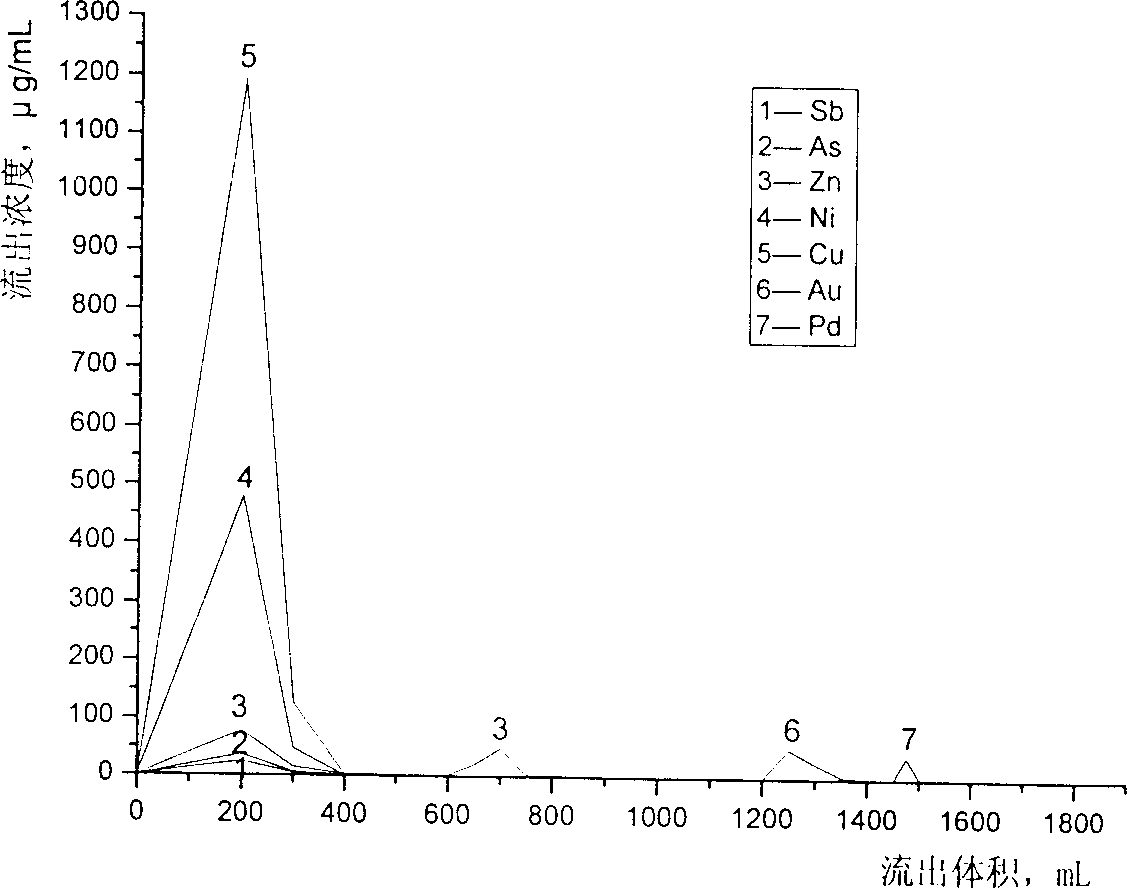

Method for separating platinum palladium iraurita

InactiveCN1400322AAchieve mutual separationEasy to separateProcess efficiency improvementIridiumThiourea

The present invention uses weak base phenylethylene series trialkylamine type anion-exchange resin as fixed phase and uses hydrochloric acid medium as mobile phone to implement coarse separation of platinum, palladium, iridium and gold from base metal, adopts dilute hydrochrolic acid, water and EDTA to elute base metal, and utilizes sulfocyanate+ascorbic acid solution, hydrochloric acid equilibrated methyl isobutanedione, NH4Cl+NH3.H2O solution and HCl+thiourea+thiourea+methyl alcohol solution to selectively shower-wash iridium, gold, palladium and platinum, and its chromatographic column canbe regenerated by using hydrochloric acid. Its resolution is good, the baseline separation can be obtained, and their recoveries are above 95%.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

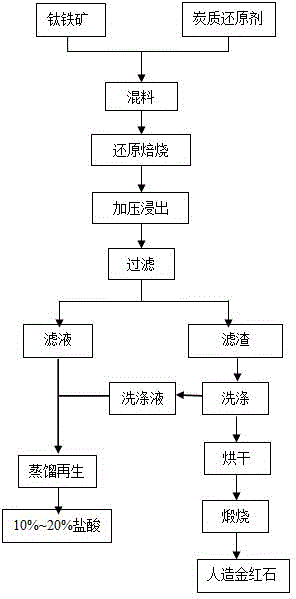

Process for making artificial rutile by leaching of mohsite hydrochloric acid

The invention relates to a process for making artificial rutile by leaching of mohsite hydrochloric acid and belongs to the technical field of metallurgy. The process includes using mohsite graded at 45-52% as raw materials, and distributing carbonaceous reducing agent for reducing roasting, pressure leaching, filtering, roasting, and regenerating of hydrochloric acid, so that impurity removal of mohsite and recycling of hydrochloric acid are effectively realized and artificial rutile is made. The process is characterized in that mohsite and carbonaceous reducing agent are uniformly mixed for reducing roasting, and leaching rate of impurities like silicon, iron, calcium and magnesium is increased; hydrochloric acid is regenerated by distilling leaching mother liquor and can be reused in leaching; filter slag can be roasted after pressurized leaching and filtering so as to obtain artificial rutile. The process has the advantages of high leaching speed, high impurity removal efficiency, high grade and recyclability of hydrochloric acid. In addition, the process is applicable to industrial production in the aspects of technique, equipment, economy and environment protection.

Owner:KUNMING METALLURGY INST

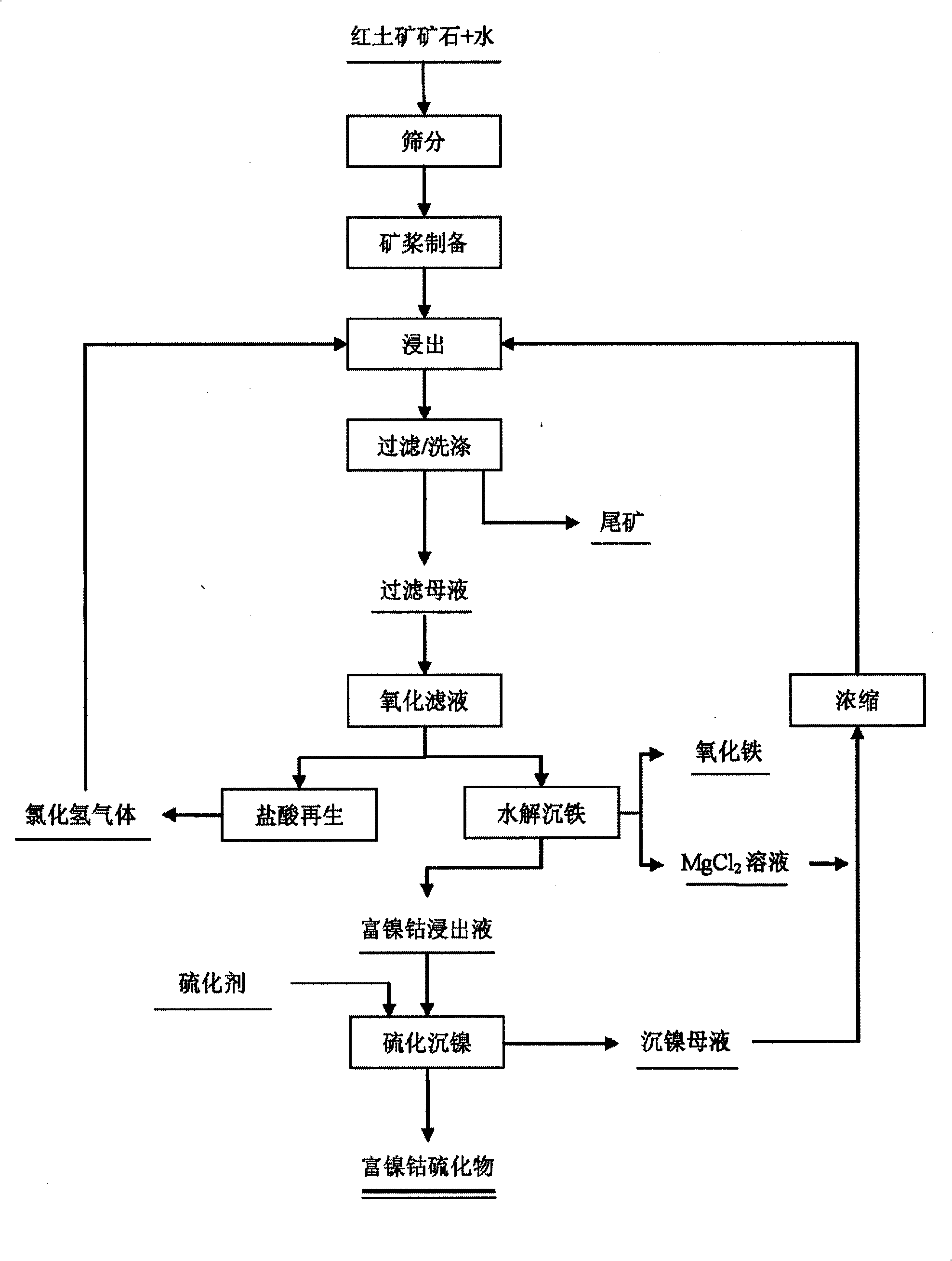

Method for comprehensive exploitation of low-ore grade laterite nickel mine

ActiveCN101403035ASimple processReduce manufacturing costIron oxides/hydroxidesProcess efficiency improvementLateriteHydrolysis

The invention discloses a method for comprehensively developing low-grade nickeliferous laterite ore. The main technique comprises the steps of the preparation of minerals, chlorination and leaching, the oxidation of leachate, the regeneration of hydrochloric acid and the hydrolysis of settled iron, solid-liquid separation, sulfuration and sediment and the recycling of chloride and the like; the method is characterized in that the nickeliferous laterite ore is leached out by hydrochloric acid and the chloride at normal pressure and iron in the nickeliferous laterite ore is leached out as much as possible; leached ferrous ions are oxidized into ferric ion; the regeneration of hydrochloric acid and hydrolysis of settled iron are realized synchronously under the condition of normal pressure and the temperature of 140 to 180 DEG C; the collection of the regenerated hydrochloric acid prompts the hydrolysis reaction to be complete so as to obtain iron oxide red of byproduct; and after solid-liquid separation, filtrate enriched with nickel and cobalt carries out sulfuration and sediment and chloride solution is recycled. The invention discards the method of pyrohydrolysis or high-temperature roasting in the traditional technique, reduces the energy consumption of removal of iron and the regeneration of hydrochloric acid, improves the leaching rate of the nickel and cobalt and simultaneously develops and utilizes base metal in the ore reasonably so as to increase the additional value of the technique.

Owner:CENT SOUTH UNIV

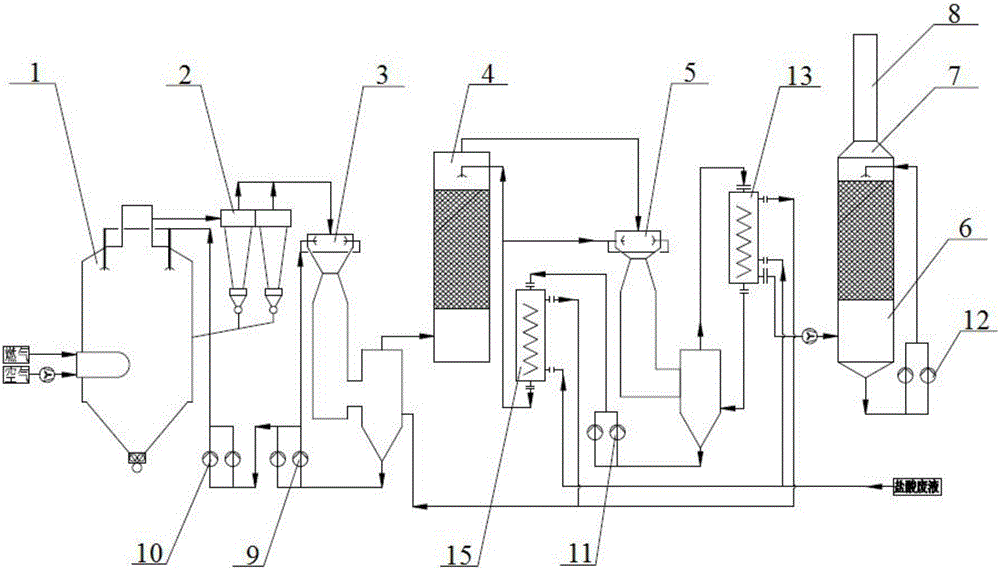

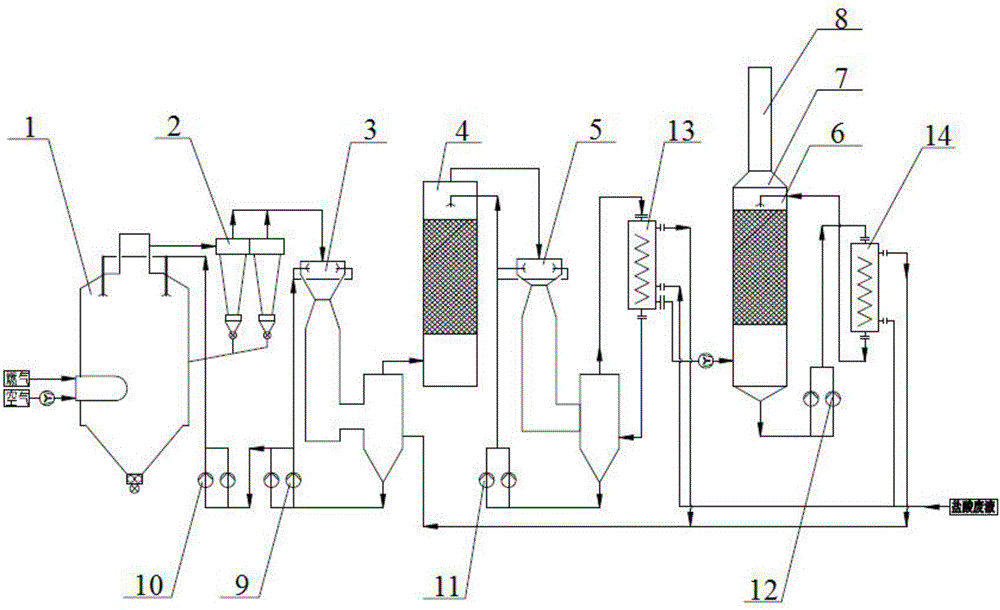

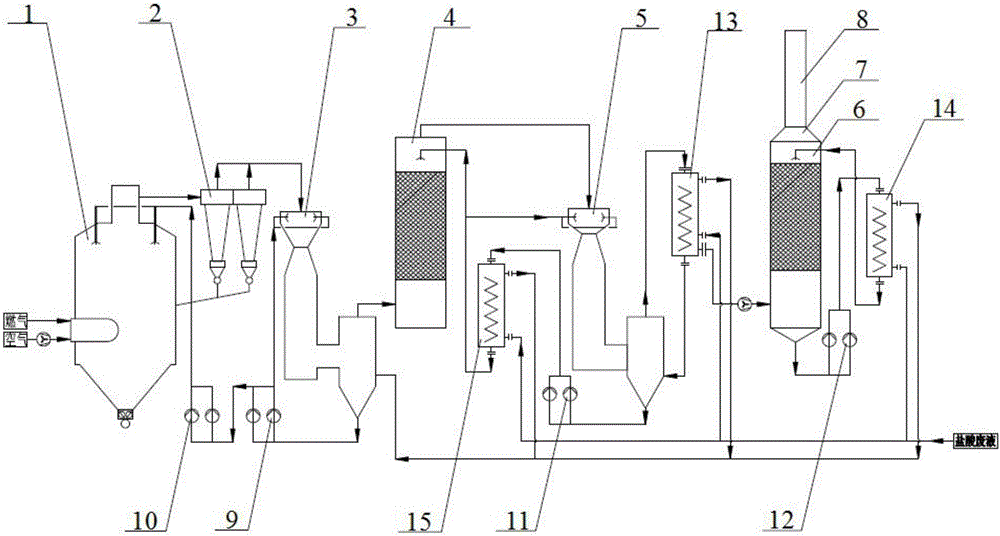

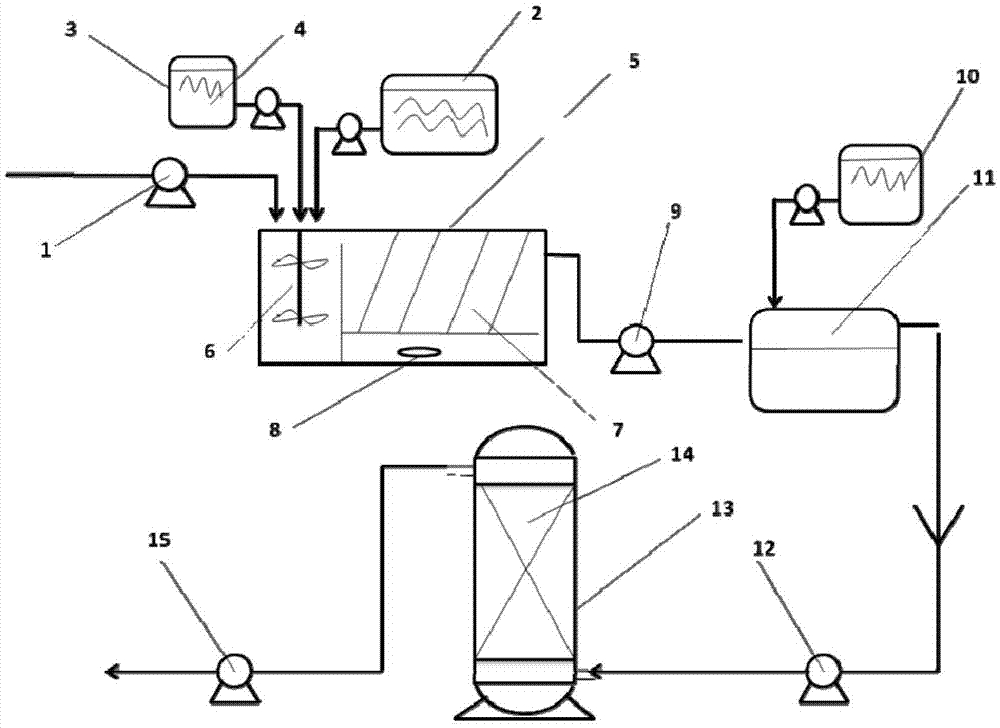

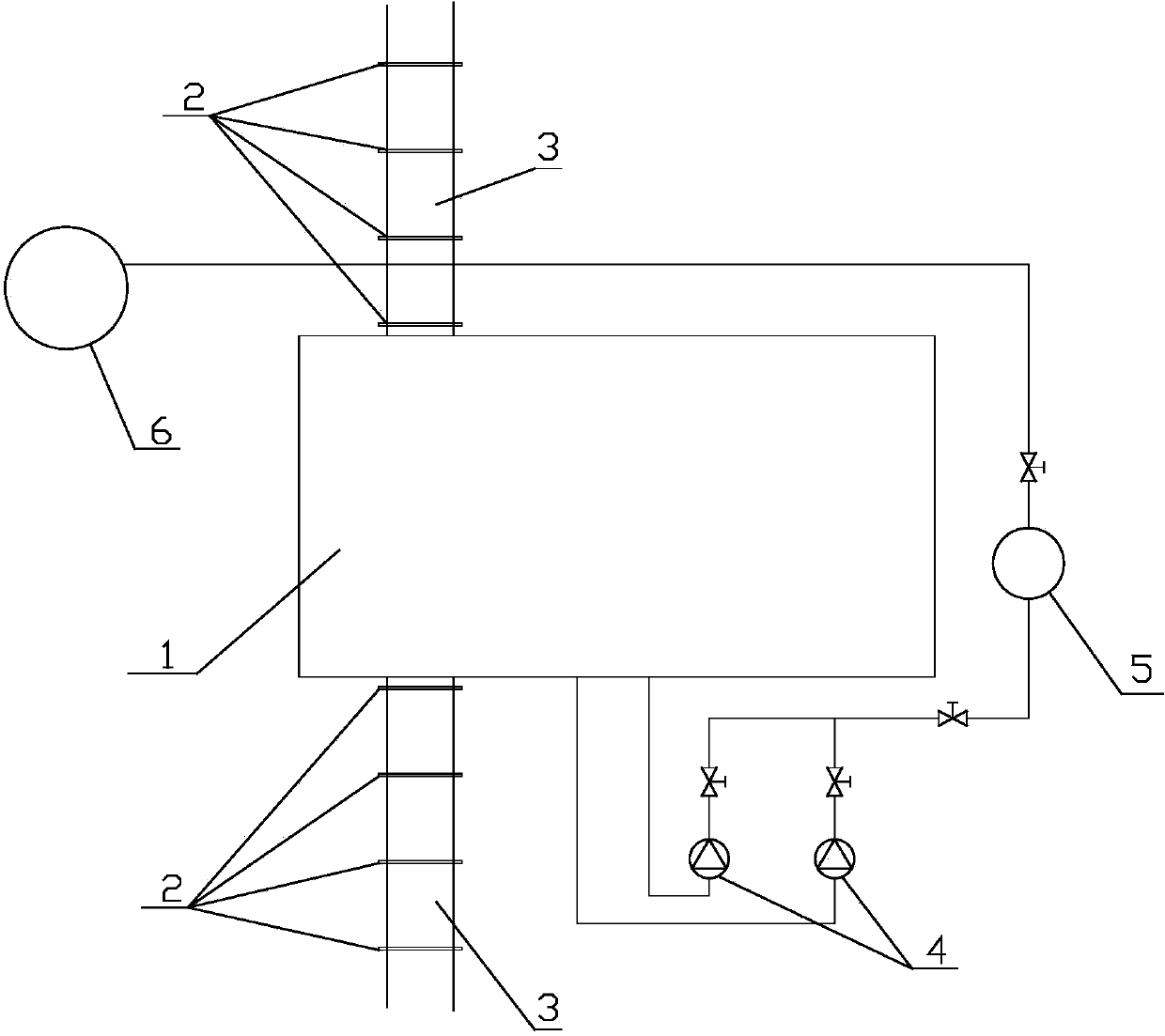

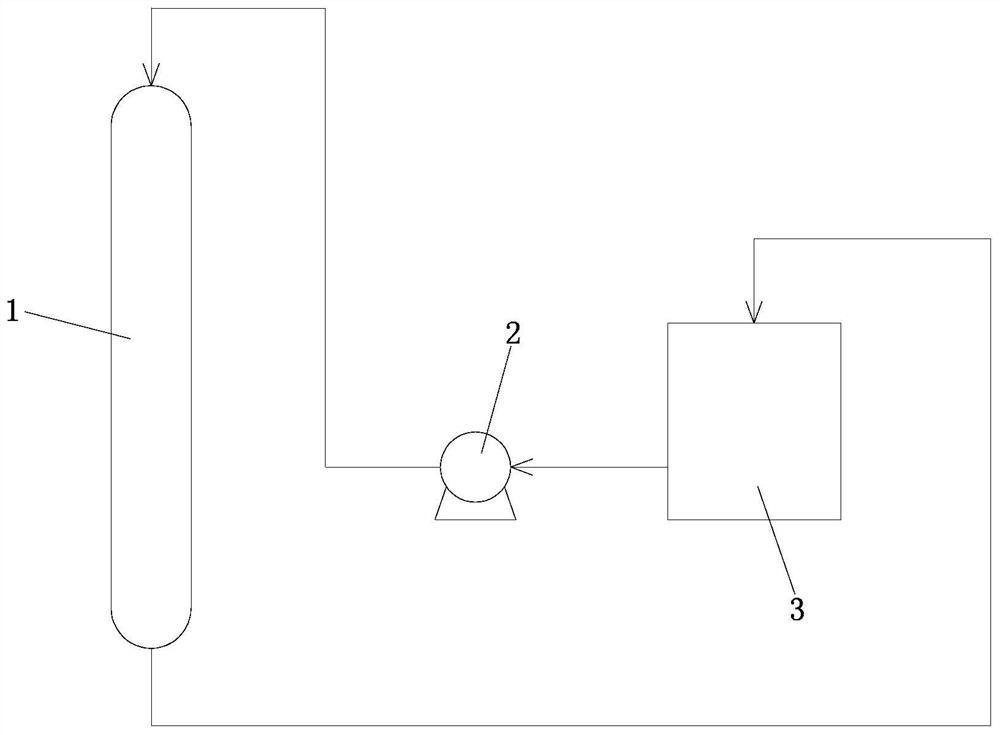

Method and system for regenerating hydrochloric acid waste liquid

ActiveCN105879580AReduce wasteImprove recycling efficiencyGas treatmentChlorine/hydrogen-chloride purificationLiquid wasteLiquid storage tank

The invention relates to a method for regenerating hydrochloric acid waste liquid. According to the method, a spray roasting method is adopted, and the hydrochloric acid waste liquid is preheated through circulating liquid in at least one washing mechanism in the second-stage washing mechanism and washing mechanisms behind the second-stage washing mechanism. The invention further relates to a system for regenerating the hydrochloric acid waste liquid. The system comprises a roasting furnace, a Venturi preconcentrator, an absorption tower and multiple stages of washing mechanisms, all of which are sequentially connected through a smoke pipeline, and a third heat exchange mechanism is arranged on a circulating liquid pipeline of at least one of the second-stage washing mechanism and the washing mechanisms behind the second-stage washing mechanism. Refrigerant inlets of all the third heat exchange mechanisms are connected with a hydrochloric acid waste liquid storage tank, and refrigerant outlets are all connected with the Venturi preconcentrator. The hydrochloric acid waste liquid is preheated through the circulating liquid of the corresponding washing mechanisms, energy saving and consumption reducing are achieved, and the regenerating and recycling efficiency of the hydrochloric acid waste liquid can be improved. Meanwhile, the circulating liquid of the corresponding washing mechanisms is cooled, the heat exchange amount of the low-temperature circulating liquid and smoke is larger, and the washing effect of the washing mechanisms can be improved.

Owner:WISDRI ENG & RES INC LTD

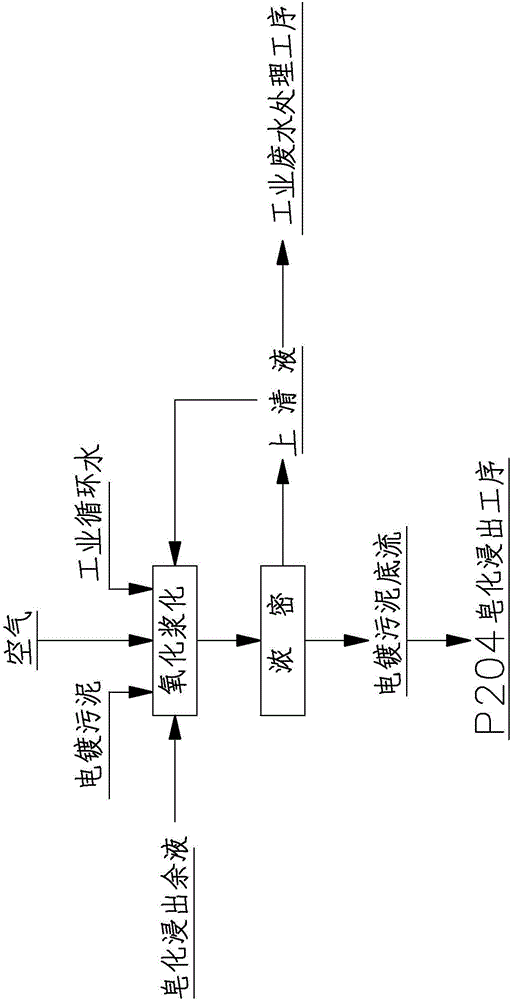

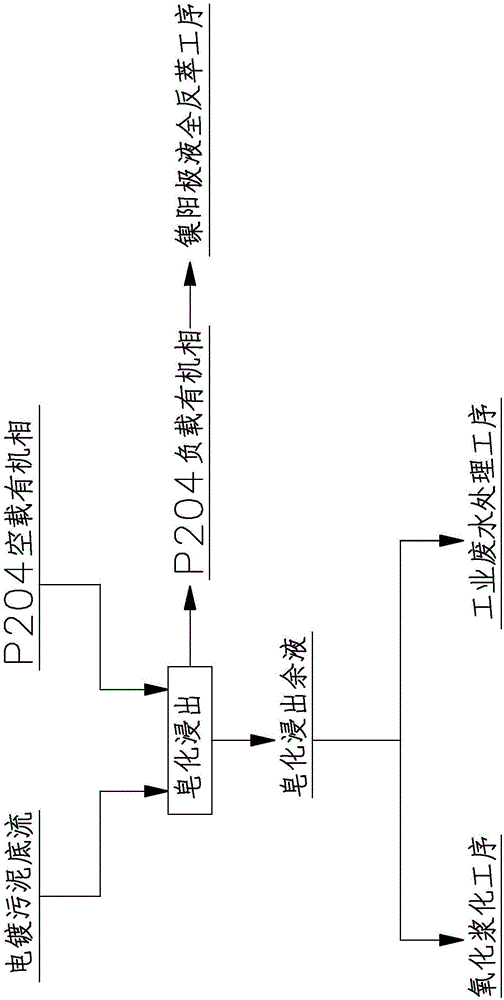

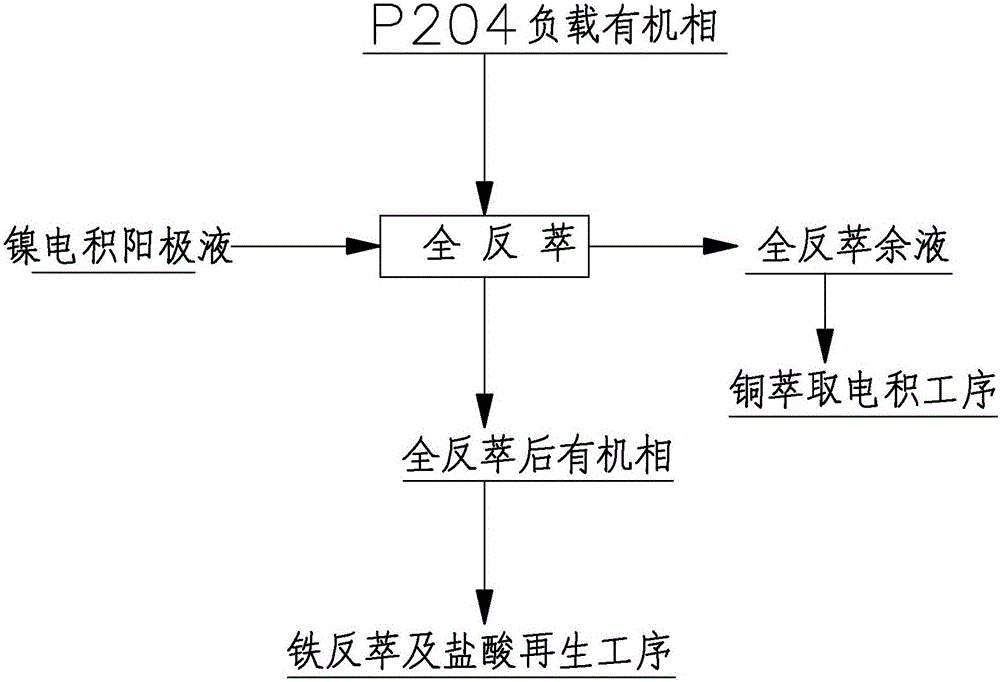

Method for comprehensively recycling multiple valuable metals from electroplating sludge

ActiveCN105907972ASolve industrial wasteSolve the neutralization problemPhotography auxillary processesProcess efficiency improvementSludgeSaponification

The invention discloses a method for comprehensively recycling multiple valuable metals from electroplating sludge. According to an existing adopted chemical method for treating electroplating sludge, the treating cost stays at a high level, and moreover a large amount of industrial wastewater needing to be subjected to secondary treating is produced. According to the adopted technical scheme, the method for comprehensively recycling the multiple valuable metals from the electroplating sludge comprises the processes of oxidation slurrying, P204 saponification leaching, nickel anode electrolyte complete back extraction, iron back extraction and hydrochloric acid regeneration, copper extraction electrodeposition, chromium deposition, P204 nickel saponification, P204 zinc extraction electrodeposition, nickel electrodeposition, calcium-nickel separation, magnesium-calcium separation and industrial circulating water treating. The problem that a large amount of water of the electroplating sludge enters a system in the process that the valuable metals are recycled from the electroplating sludge through the chemical method is solved, the valuable metals in the electroplating sludge enter organic phases through saponification leaching, and the self-carried water of the electroplating sludge is blocked outside the system.

Owner:桐乡市思远环保科技有限公司

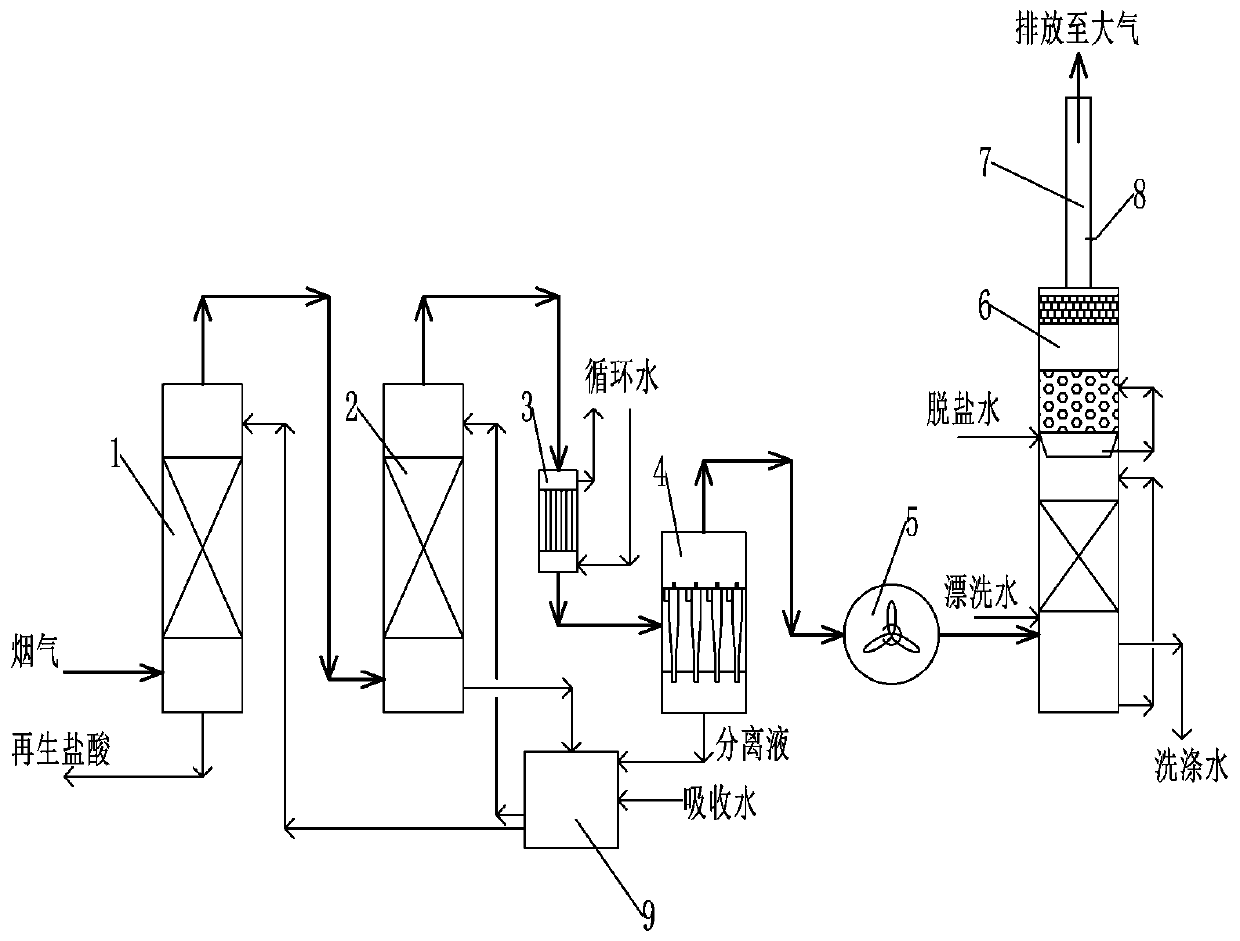

Technology and system for treating hydrochloric acid regeneration device tail gas

InactiveCN104857829AImprove pollution statusEmission reductionDispersed particle separationComing outCooling tower

The invention relates to a technology and a system for treating hydrochloric acid regeneration device tail gas. The technology comprises steps as follows: 1) the hydrochloric acid regeneration device tail gas coming out of an absorption tower enters a condenser to indirectly exchange heat with cooling water, and condensate formed after condensation of part of water vapor in the tail gas enters a collecting water tank to be used as a spraying liquid of the absorption tower; 2) the cooling water is heated through heat exchange, then enters a cooling tower and returns to the condenser for recycling after cooled again; 3) the tail gas comes out of the condenser, is pressurized by a smoke exhaust fan and enters an alkaline washing tower, hydrochloric acid in the alkaline washing tower is thoroughly neutralized, and the acid content of the finally discharged tail gas is smaller than or equal to 10 mg / m<3>. With the adoption of the technology and the system, up-to-standard discharge of the hydrochloric acid regeneration device tail gas is realized, meanwhile, the process cooling water can be recycled, the condensate is used as the spraying liquid of the absorption tower, so that water for washing is saved, and power consumption is reduced; the total discharge amount of the tail gas can be reduced, the load of the smoke exhaust fan is reduced, and the technology is simple and easy to implement, low in investment and particularly applicable to transformation of old plants, takes effect quickly and is another good method worthy of popularization for energy conservation and emission reduction.

Owner:鞍山创鑫环保科技股份有限公司

Method and apparatus for reducing electrical conductivity and total iron in cold-rolled hydrochloric acid regeneration wastewater

ActiveCN106977003AEasy to settleEasy to form when precipitatedWater treatment parameter controlWaste water treatment from metallurgical processCalcium hydroxideWastewater

The invention relates to a method and an apparatus for reducing the electrical conductivity and the total iron in cold-rolled hydrochloric acid regeneration wastewater. According to the present invention, cold-rolled hydrochloric acid regeneration wastewater enters an integrated agent adding precipitation pool, 1000-2500 mg / L calcium hydroxide or sodium hydroxide is added to the integrated agent adding precipitation pool, the PH value is controlled at more than 10, a 5-15 mg / L in-situ compound auxiliary coagulant is added, the cold-rolled hydrochloric acid regeneration wastewater, the calcium hydroxide or sodium hydroxide, and the in-situ compound auxiliary coagulant are mixed and stirred at the front portion of the integrated agent adding precipitation pool, the mixture enters a PH value adjustment pool, the PH value of the wastewater is adjusted to 6-9, and the PH value adjusted wastewater enters a fly ash adsorption tower and is subjected to periodic backwashing treatment so as to obtain the treated cold-rolled hydrochloric acid regeneration wastewater; and with the technical scheme, the environmental pollution can be reduced, and the increasingly stringent environmental protection laws and regulations can be met.

Owner:BAOSHAN IRON & STEEL CO LTD

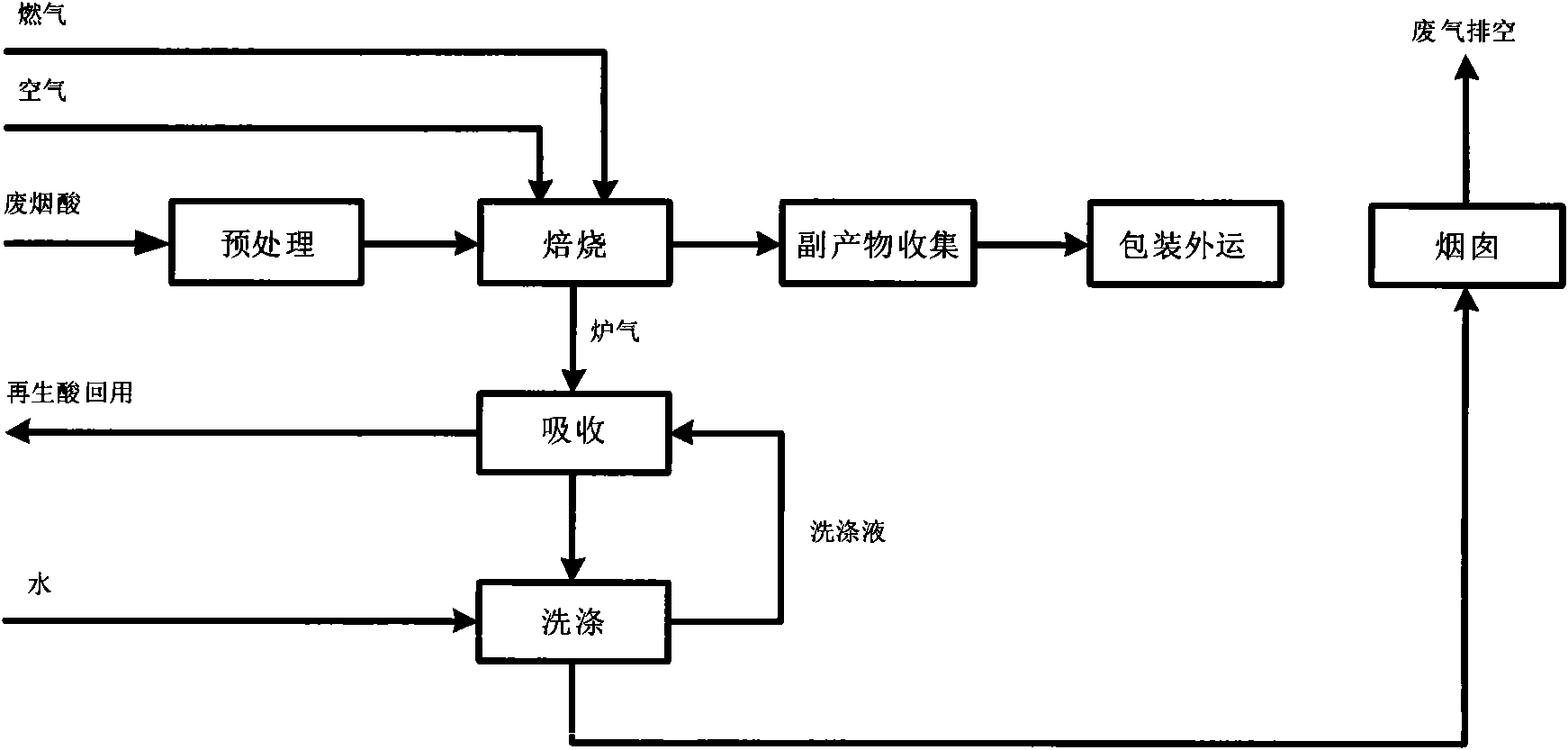

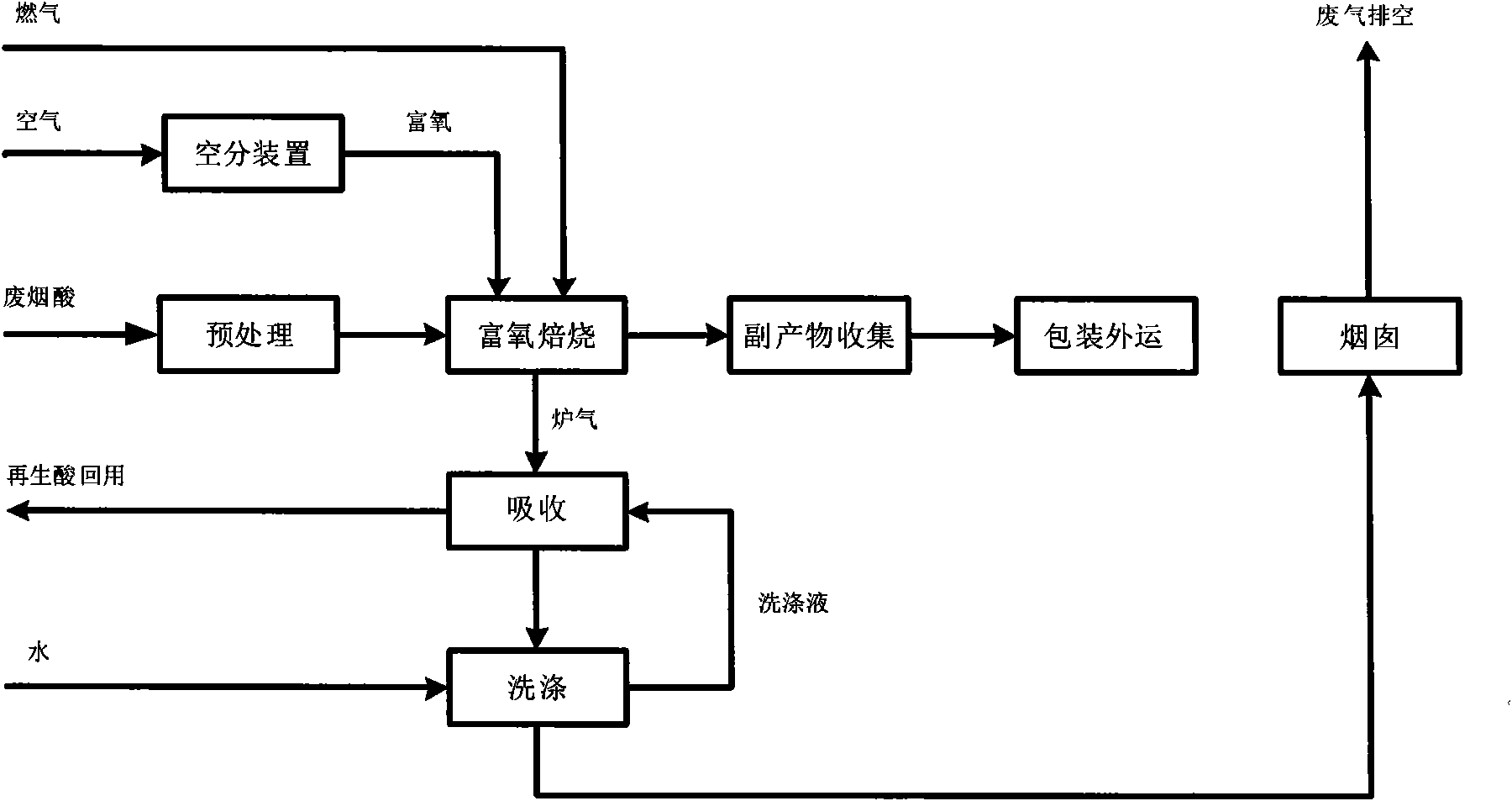

Method for regeneration of waste hydrochloric acid by oxygen enriched roasting

InactiveCN101654224AEasy to handlePromote combustionChlorine/hydrogen-chloride purificationAir separationSpent acid

The invention provides a method for the regeneration of waste hydrochloric acid by oxygen enriched roasting. The method is characterized in that: air separation technology is adopted to separate air to extract enriched oxygen of which the purity is 22 to 95 percent, and the enriched oxygen is used to replace air to serve as the roasting combustion-supporting gas in the roasting treatment for the oxygen enriched roasting of the waste hydrochloric acid. The method has the advantages of greatly improving treating ability of a waste acid regenerating device, lowering energy consumption of the system, and lowering production cost of regenerating the waste hydrochloric acid.

Owner:CHENGDU HUAXI CHEM TECH CO LTD

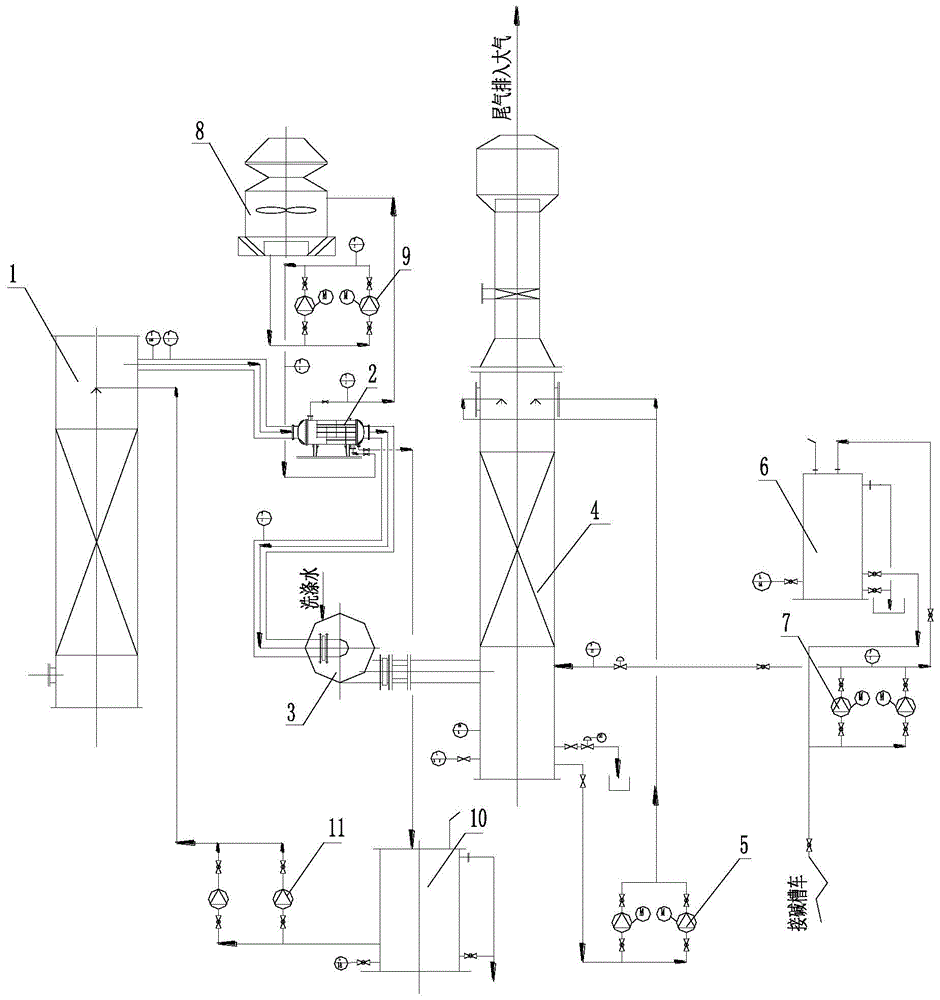

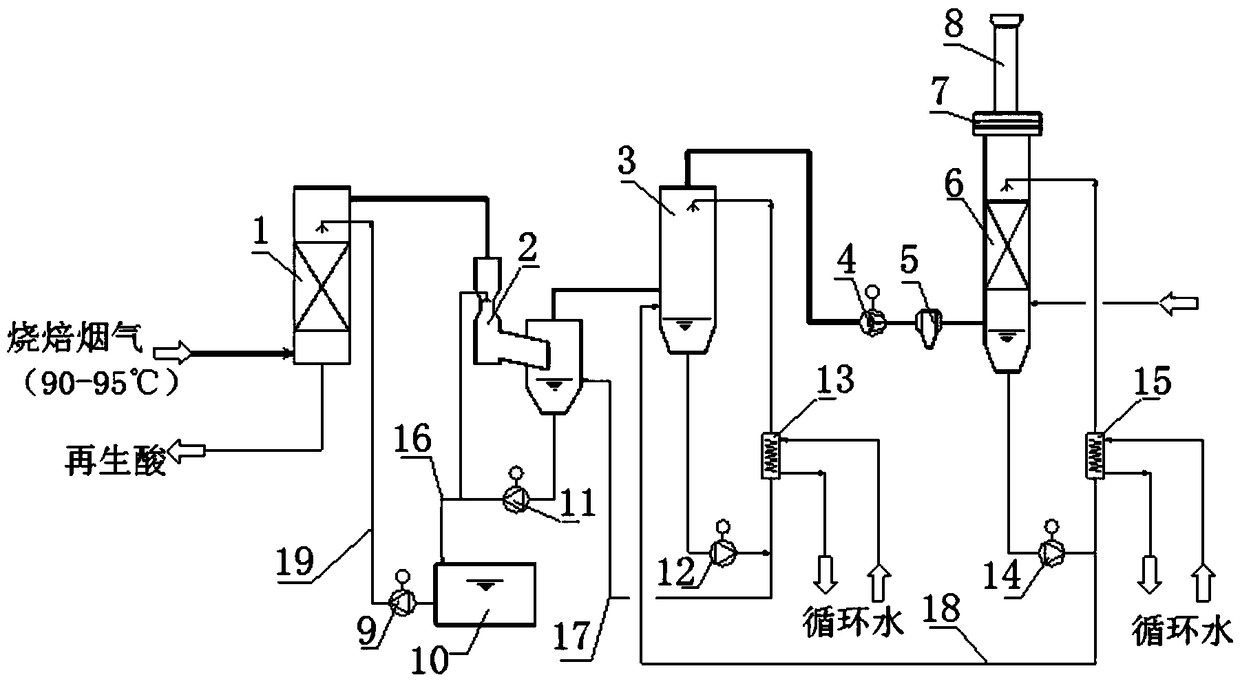

Hydrochloric acid regenerating device and process for flue gas cooling

InactiveCN108654312AReduce gas massSmall volumeGas treatmentUsing liquid separation agentCooling towerAtmospheric air

The invention discloses a hydrochloric acid regenerating device and process for flue gas cooling. The hydrochloric acid regenerating device comprises an absorption tower, a first-stage washing tower,a spray cooling tower, an exhaust fan, a first-stage gas-liquid separator, a second-stage washing tower, a second-stage gas-liquid separator and a chimney; the spray cooling tower is an empty tower filled with no filler; circulating liquid pipelines of the spray cooling tower and the second-stage washing tower are respectively provided with a first heat exchanger and a second heat exchanger; and each of the heat exchangers is connected with a circulating cooling water pipeline. The hydrochloric acid regenerating device is used for treating and cooling flue gases generated after a hydrochloricacid regenerating reaction realized by a spray roasting method or a fluidized bed method and ensuring that the concentration of pollutants in the flue gases reaches a relatively low concentration, thetemperature of the discharged flue gas can reach about 45-50 DEG C, the content of water vapor discharged into the atmosphere is low, the contents of hydrogen chloride and dust pollutants are extremely low, and no obvious "white steam" is generated, so that the psychologically-unpleasant sensation of the public to the "white steam" is avoided.

Owner:WISDRI ENG & RES INC LTD

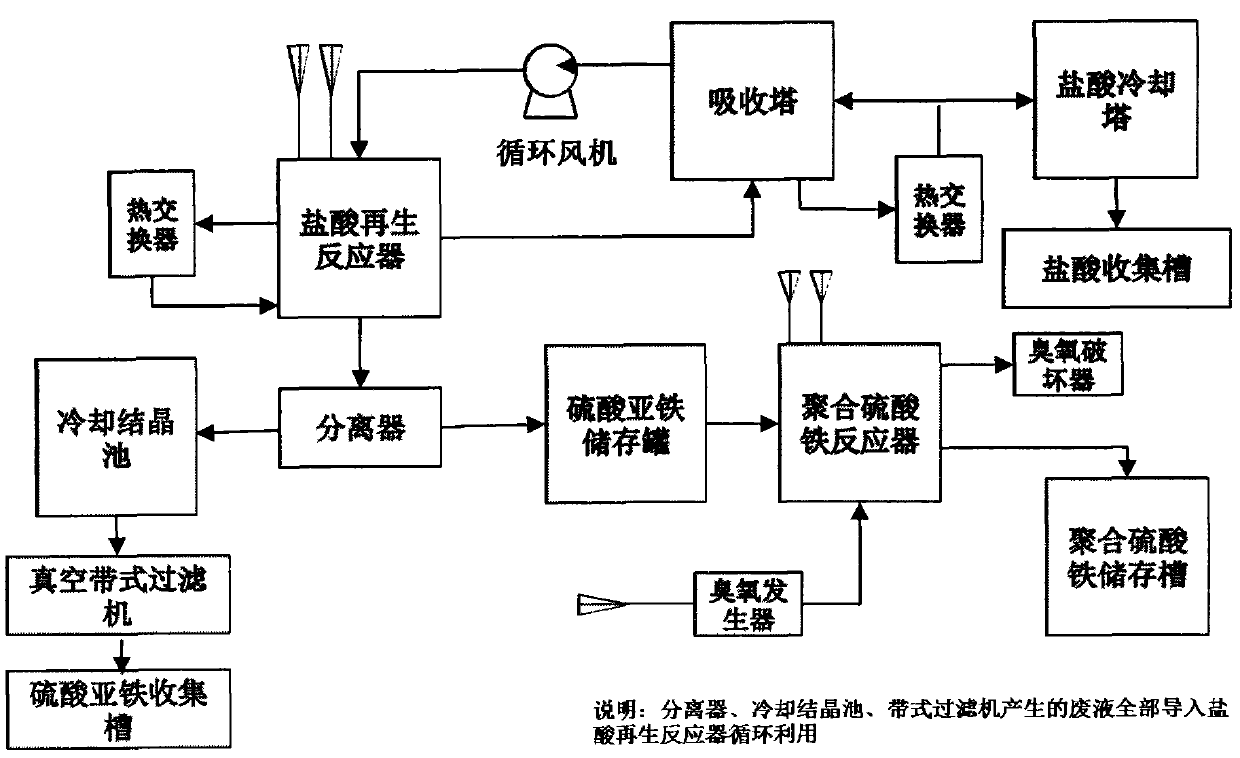

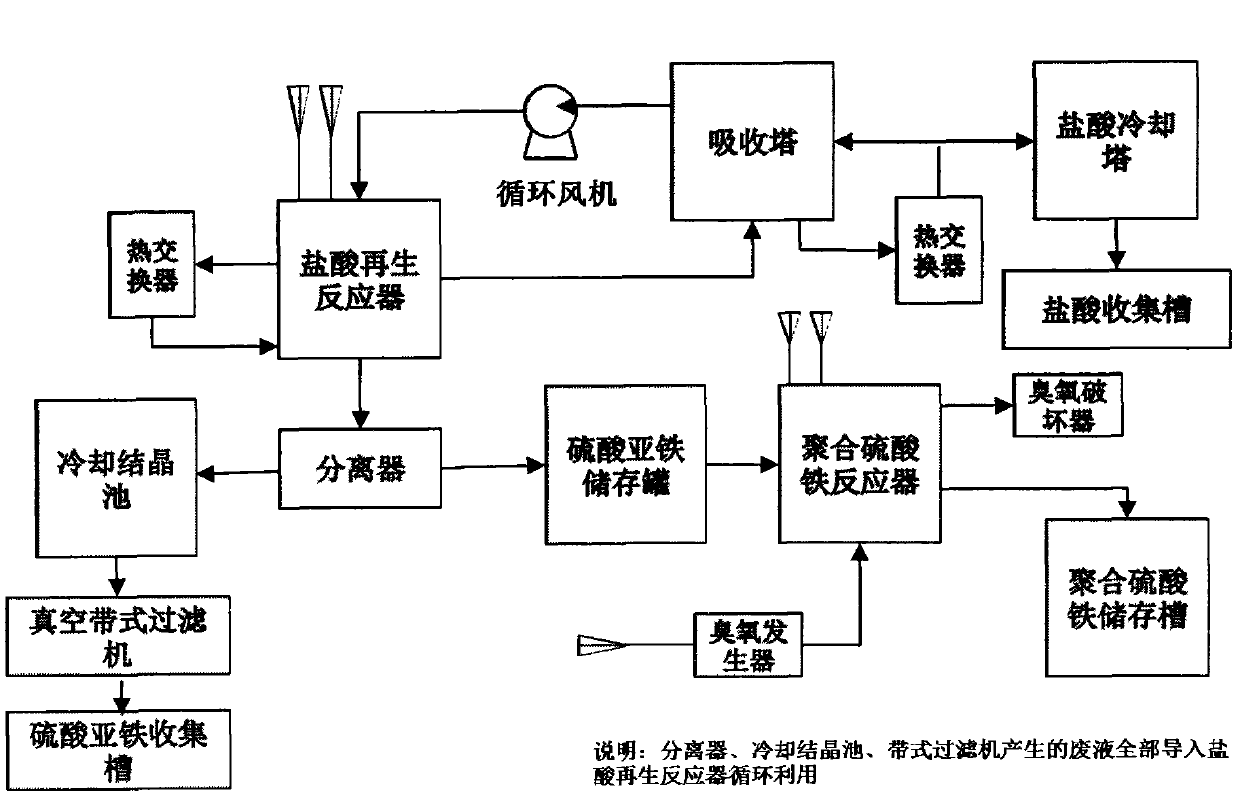

Method and device for recycling useful substances from waste hydrochloric acid liquor

InactiveCN102602890AHigh purityHigh economic valueChlorine/hydrogen-chlorideIron sulfatesLiquid wasteIron(III) sulfate

The invention relates to a method and a device for recycling waste hydrochloric acid liquor and producing ferrous sulfate and polyferric sulfate. The method and the device are mainly characterized in that a certain proportion of concentrated sulfuric acid is added into a hydrochloric acid regeneration reactor internally containing the waste hydrochloric acid liquor, produced regenerative acid vapor is cooled to obtain regenerative hydrochloric acid, residual liquor in the hydrochloric acid regeneration reactor passes through a separator and is cooled, crystallized, filtered in vacuum and dried to obtain ferrous sulfate crystal, and the residual liquor can also pass through the separator and a ferrous sulfate storage tank and can be oxidized by ozone in a polyferric sulfate reactor to obtain the polyferric sulfate. The method and the device are simple and convenient in process, low in investment, high in recycling rate and applicable to recycling of a large amount of pickling waste liquor, and the economic value of recycling of the waste liquor is improved.

Owner:ENDIAN HUIZHI BEIJING INVESTMENT MANAGEMENT

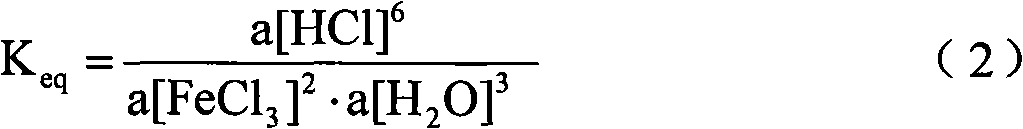

Process for regenerating hydrochloric acid for chloridizing laterite nickel ore by wet method

ActiveCN101306797AReduce dosageFully utilized heatChlorine/hydrogen-chlorideMagnesium chloridesSlurryLaterite

The invention relates to a method for reproduction and utilization of hydrochloric acid in the process of extracting nickel and cobalt from laterite nickel ore. A chlorination treatment process of laterite nickel ore by wet method comprises the steps of preparing laterite nickel ore, leaching out chloride, concentrating leaching solution, precipitating by sulfurization, recovering hydrochloric acid, etc. The calcinating materials in the inventive hydrochloric acid reproduction process comprise the concentrated solution of the mother liquid after nickel precipitation, iron chloride and magnesium chloride crystals obtained during concentration of the leaching solution, and coal powder. The inventive method comprises the steps of mixing and blending materials to obtain slurry, and spraying into a high-temperature furnace, or calcinating the materials in high-temperature furnaces at 500-800DEG C, hydrolyzing metallic chloride into hydrogen chloride and metal oxide, heating the concentrated leaching solution by using the residual heat from the hot furnace gas, and absorbing the hydrogen chloride to reproduce hydrochloric acid, so as to realize closed circuit circulation of the hydrochloric acid. The high-viscosity ferric oxide and magnesium oxide dregs are cooled, broken and pulverized to powder, which is used as a byproduct for treatment. The inventive method improves the conversion rate and equipment productive capacity during chloride reproduction process, reduces energy consumption in hydrochloric acid reproduction, and realizes comprehensive utilization of the residual heat in hydrochloric acid reproduction.

Owner:CENT SOUTH UNIV

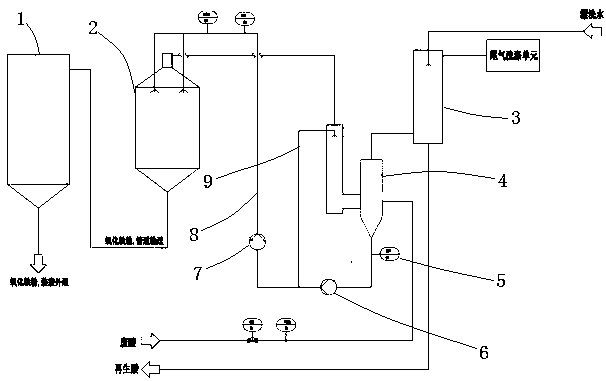

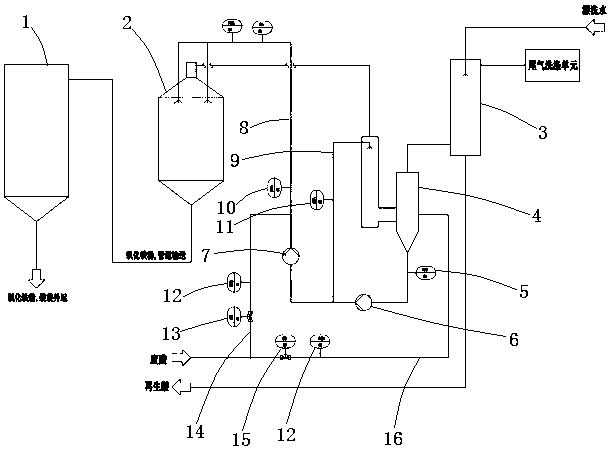

Acid-containing wastewater recycling device and method for hydrochloric acid regenerator set

The invention relates to an acid-containing wastewater recycling device and an acid-containing wastewater recycling method for a hydrochloric acid regenerator set. The acid-containing wastewater recycling device comprises a pit, pit pumps and ditches, wherein the pit pumps are respectively connected with the pit and the regenerator set; the ditches are communicated with the pit. The acid-containing wastewater recycling device also comprises grates, an acidproof filter, a pipe fitting and filter nets; three or more grates are uniformly distributed on the ditches close to the pit; a distance between adjacent grates is 0.8-1.5m; the filter nets are arranged on the adjacent grates; outlets of the pit pumps are connected with the acidproof filter; the filter precision of the acidproof filter is 50-80 microns. The acid-containing wastewater recycling device for the hydrochloric acid regenerator set has the advantages that acid-containing water can be recycled and used, emission of hydrochloric acid is alleviated, pollution of chloride ions to the environment is relieved, and the energy consumption of new hydrochloric acid is reduced; wastewater cannot be discharged to a neutralization station, so that the neutralization station is in a non-use state, and the pollution to the environment is relieved.

Owner:ANGANG STEEL CO LTD

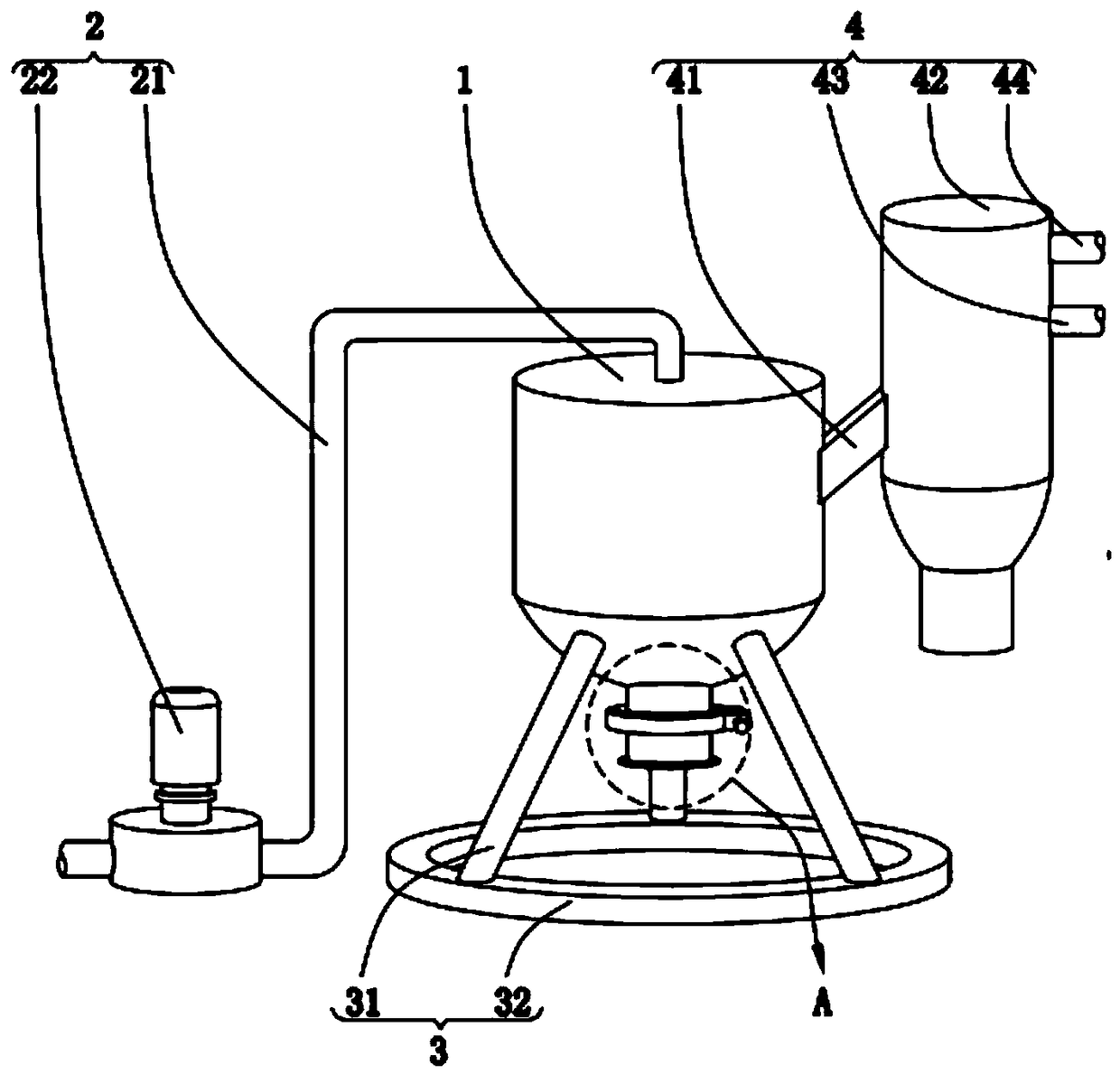

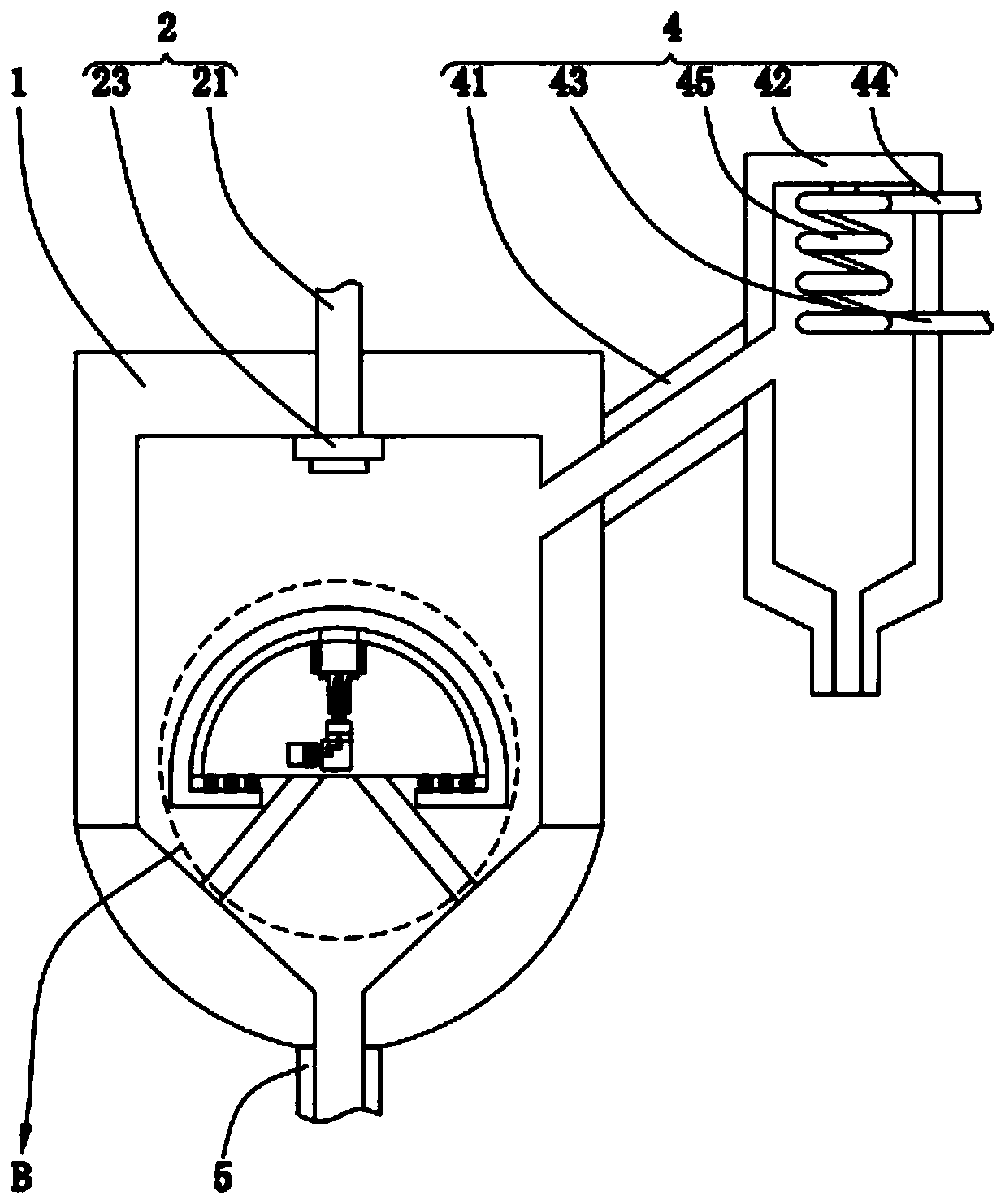

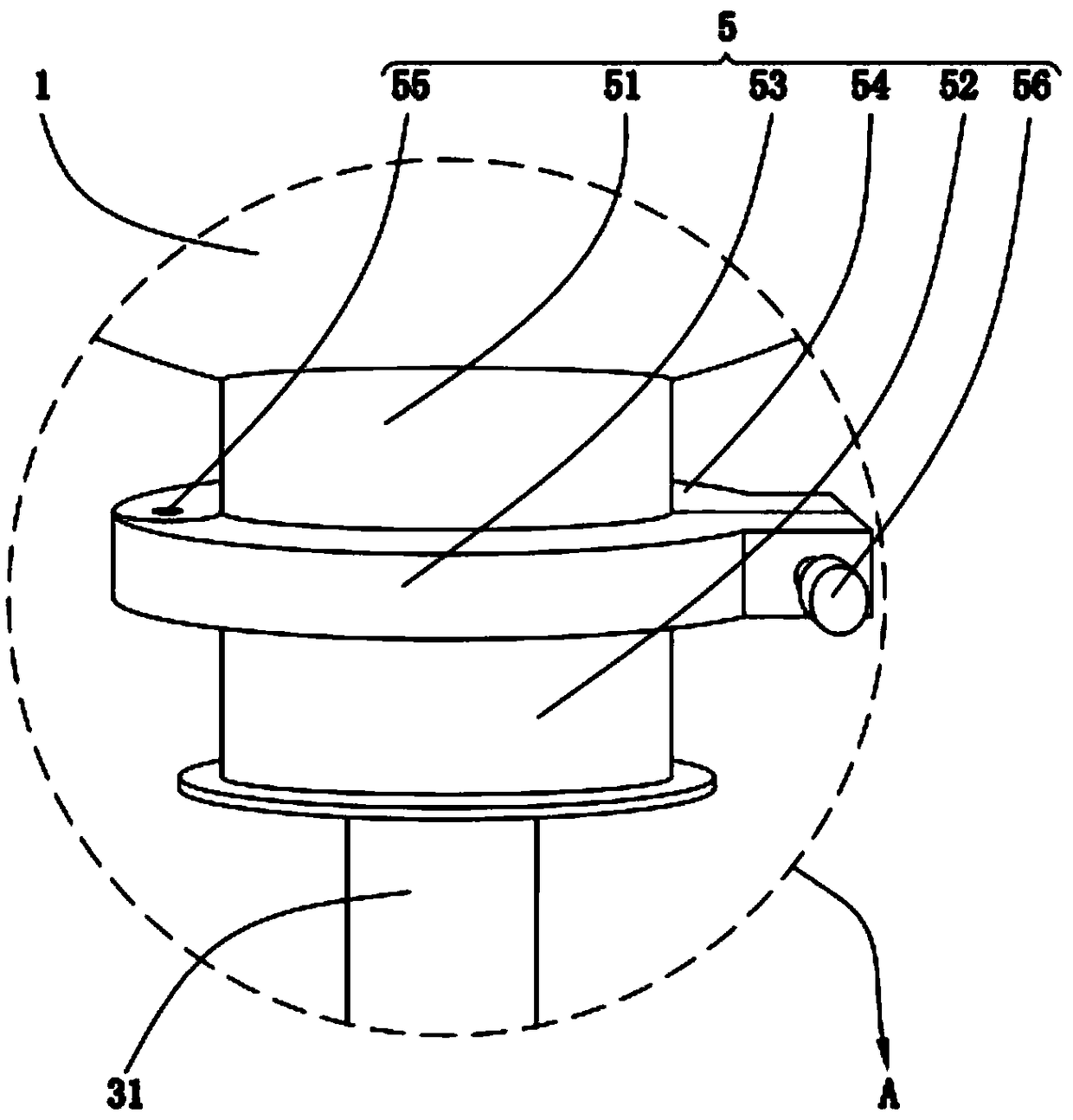

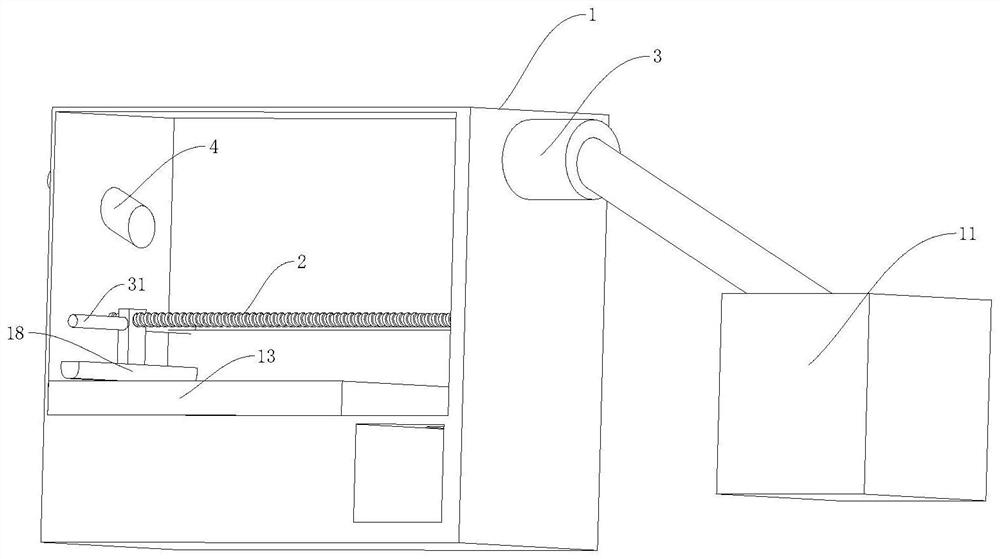

Concentrated hydrochloric acid recycling mechanism used for hydrochloric acid regeneration

The invention belongs to the field of waste acid regeneration recycling, and more specifically relates to a concentrated hydrochloric acid recycling mechanism used for hydrochloric acid regeneration.The concentrated hydrochloric acid recycling mechanism used for hydrochloric acid regeneration comprises a roasting furnace, a feeding mechanism, a fixed supporting mechanism, a condensation mechanism, a collecting mechanism, a roasting mechanism, a shocking mechanism, and a driving mechanism; the feeding mechanism which is used for introducing waste acid liquid into the roasting furnace is connected with the top end of the roasting furnace; the roasting mechanism which is used for roasting waste acid liquid after atomization is arranged at the bottom of the inner cavity of the roasting furnace; the roasting mechanism comprises fixing rods, a fixing pedestal, an electric heating plate, a dust falling plate, and first springs; the shocking mechanism which is used for shocking down of iron powder particles formed on the surface of the dust falling plate after waste acid liquid roasting evaporation is arranged in the fixing pedestal; and the driving mechanism which is used for generatingcompressed air to push an impacting block to impact the dust falling plate is arranged in the fixing pedestal. The concentrated hydrochloric acid recycling mechanism can be used for shacking and collecting iron powder formed on the surface of the dust falling plate, and preventing environment pollution.

Owner:滨州高新区国有资本投资运营有限公司

Method of reducing amount of regenerated wastewater discharged from chelating resin tower

InactiveCN110203992AEmission reductionAchieve reuseOther chemical processesWater contaminantsWastewaterChelating resin

The invention discloses a method of reducing the amount of regenerated wastewater discharged from a chelating resin tower. According to the method, a regeneration process of the chelating resin toweris divided into the steps of first water washing, backwashing, hydrochloric acid regeneration, second water washing, NaOH regeneration, third water washing, brine replacement, and the like; accordingto the above steps, the wastewater is divided into wastewater of first water washing, backwashing wastewater, wastewater of hydrochloric acid regeneration, wastewater of second water washing, wastewater of NaOH regeneration, wastewater of third water washing, and wastewater of brine replacement; the wastewater from each step is recycled separately, the wastewater that meets standards is recycled as primary refined brine, and the other wastewater that does not meet the standards is re-discharged for treatment, so that the amount of the regenerated wastewater discharged from the chelating resintower is reduced. By adopting the method, the amount of the regenerated wastewater discharged from the chelating resin tower, the expense of sewage discharge, and the treatment cost of sewage discharge can be effectively reduced; in addition, most of the regenerated wastewater from the chelating resin tower is used as the primary refined brine so that the production cost can be reduced.

Owner:重庆市映天辉氯碱化工有限公司

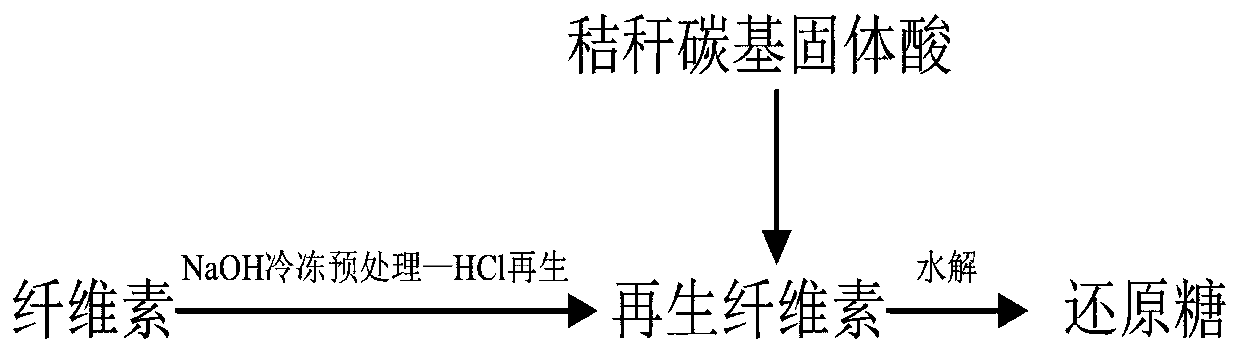

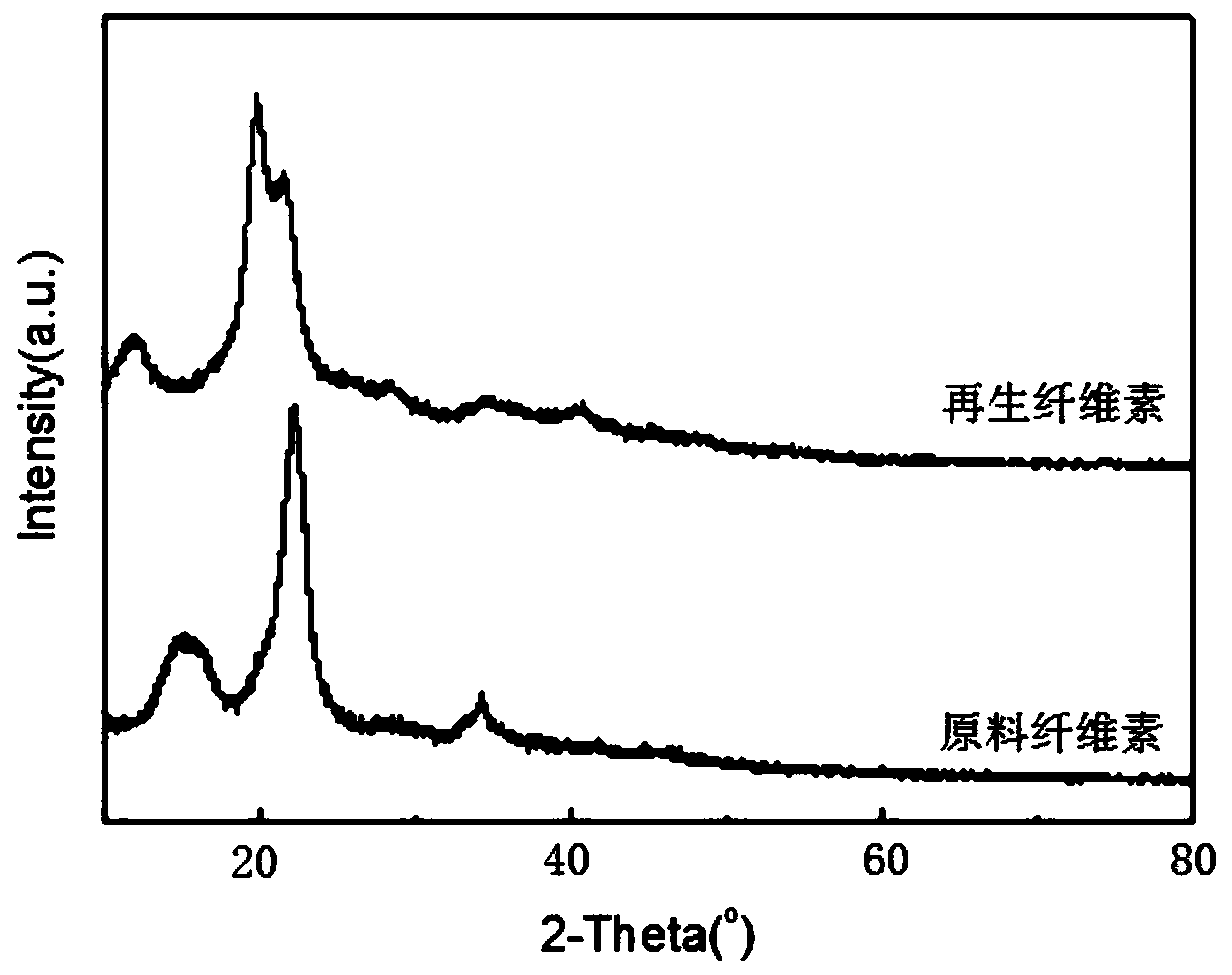

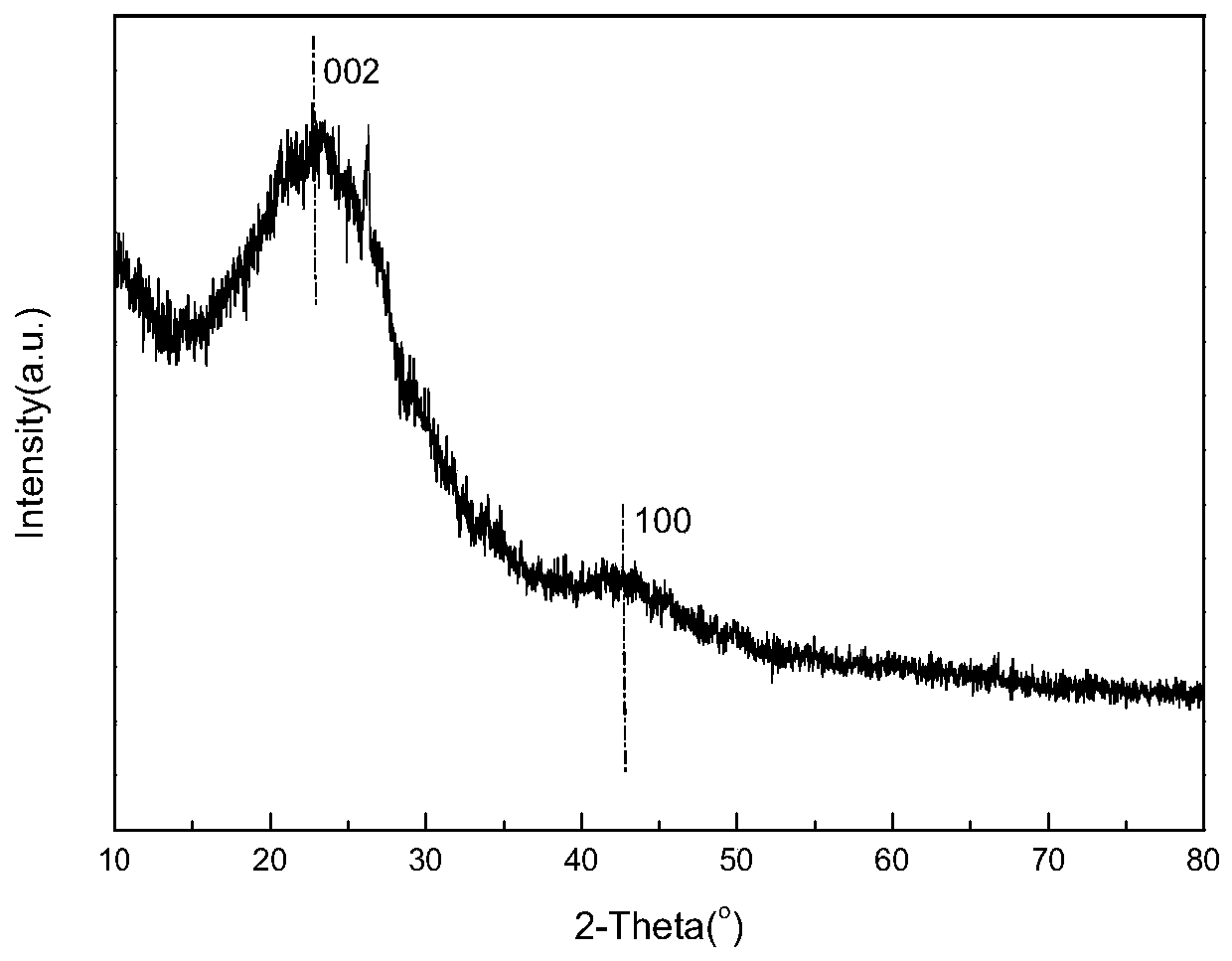

Method for hydrolyzing cellulose through cooperation between freezing pretreatment and straw carbon-based solid acid

InactiveCN110791597AReduce crystallinityImprove hydrolysis efficiencyPhysical/chemical process catalystsFructose productionPtru catalystSolid acid

The invention relates to a method for hydrolyzing cellulose through cooperation between freezing pretreatment and straw carbon-based solid acid, belonging to the technical field of cellulose hydrolysis methods. The invention aims to solve the problem of low hydrolysis efficiency of cellulose catalyzed by solid acid. The method for hydrolyzing cellulose through cooperation between freezing pretreatment and straw carbon-based solid acid comprises the following steps: performing freezing pretreatment on cellulose in an environment with a temperature of -18 to -30 DEG C, performing regeneration through hydrochloric acid to obtain regenerated cellulose with low crystallinity, hydrolyzing the regenerated cellulose by using straw carbon-based solid acid obtained by carbonizing and sulfonating crop straws as a catalyst, and efficiently converting the cellulose into reducing sugar. According to the invention, the crystallinity of the cellulose obtained through pretreatment is reduced, a contactarea of the cellulose and the catalyst can be effectively increased, and the straw carbon-based solid acid prepared through the method is high in surface acid content and high in catalytic activity and can remarkably improve the hydrolysis efficiency of the cellulose. When the method is applied to northern cold regions, pretreatment cost can be further reduced.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

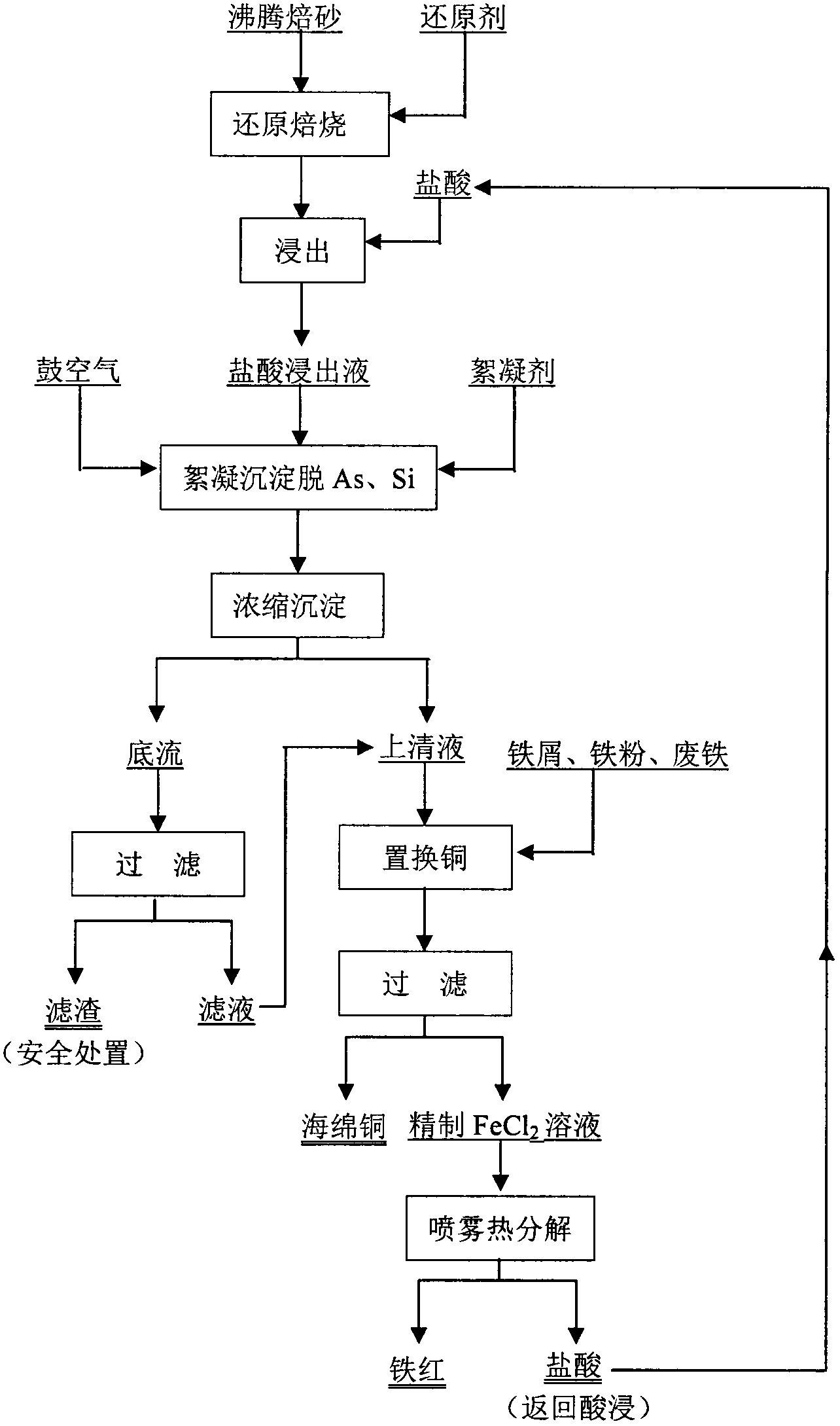

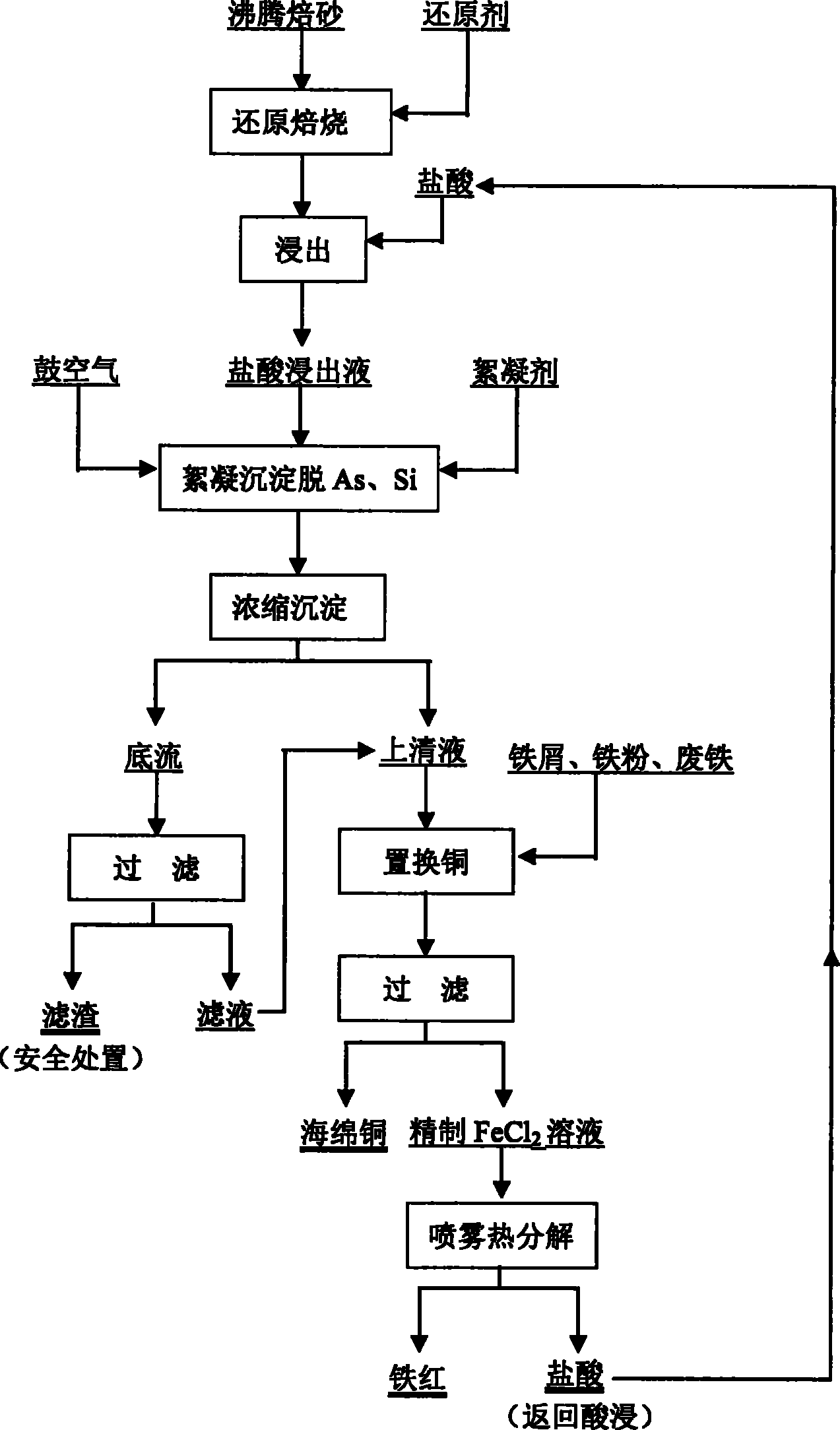

Method for preparing iron oxide red by carrying out reducing roasting on high-sulfur gold concentrate and enhancing acid solution

InactiveCN102690952AHigh recovery rateHigh regeneration rateProcess efficiency improvementSulfurCopper

The invention discloses a method for preparing iron oxide red by carrying out reducing roasting on high-sulfur gold concentrate and enhancing acid solution. In order to increase recovery rate of gold and fully utilize resources as well as realize comprehensive recovery of valuable metals, iron high-value utilization and hydrochloric acid regeneration, the method comprises the steps of: oxidizing partial Fe<2+> in an acid-soluble lixivium into Fe<3+> for removing arsenic and silicon in the solution; clarifying under the action of a flocculating agent; and then replacing copper in supernatant by adopting iron, and carrying out spraying and thermal decomposition on a refined FeCl2 solution generated after replacement to obtain iron oxide red and hydrochloric acid. According to the invention, As and Si in the acid-soluble lixivium can be respectively removed to below 50ppm and 4ppm; the recovery rate of copper is more than 99 percent, and the regeneration rate of hydrochloric acid is more than 99 percent.

Owner:CENT SOUTH UNIV

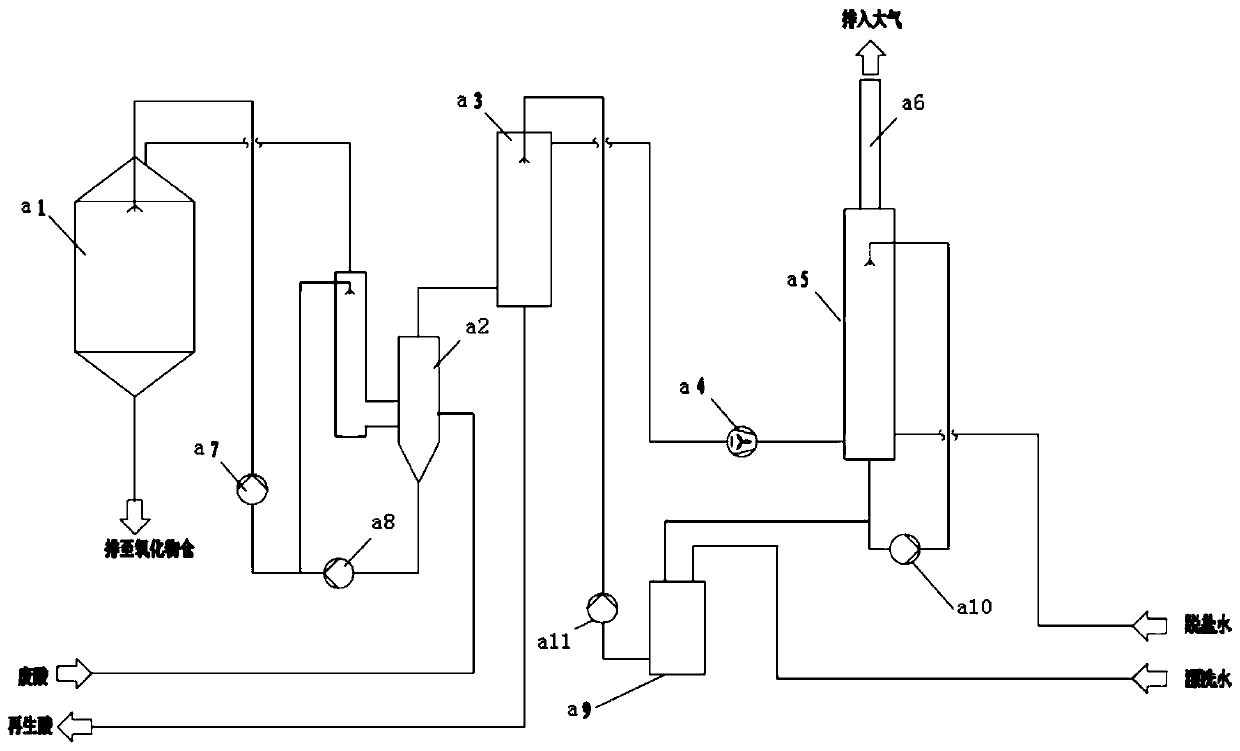

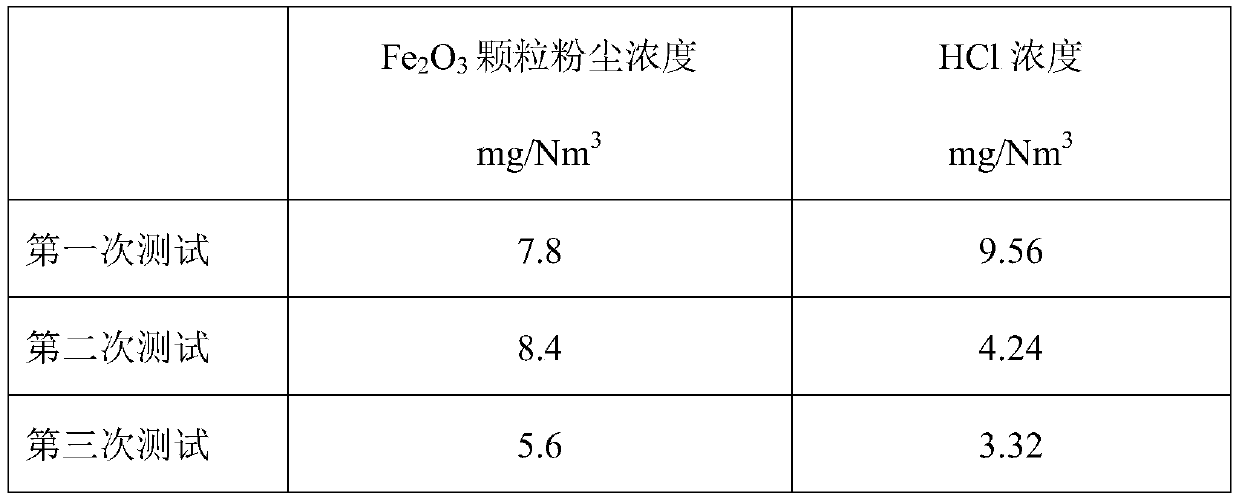

Tail gas purification system and process for spray roasting hydrochloric acid regeneration apparatus

PendingCN110124463AReduce energy consumptionRealize the function of "whitening"Combination devicesGas treatmentQuenchingGas cooling

The invention provides a tail gas purification system and a process for a spray roasting hydrochloric acid regeneration apparatus. A waste acid scrubbing tower is arranged for removing the Fe2O3 dustin the tail gas, cooling the tail gas, preheating the waste acid, and saving energy consumption. A wet electrostatic precipitator is arranged, the concentration of Fe2O3 in the tai gas is guaranteed to be lower than 10 mg / Nm3, and the national ultra-low emission standard is reached; and compared with the mechanical defogging and dust removal equipment such as wire mesh defogger and the like, the wet electrostatic precipitator cannot generate the mesh blockage problem, the energy consumption can be effectively reduced, the micron-sized droplets carried in the tail gas can also be effectively removed, and thus the tail gas "white elimination" function is realized. A venturi scrubber and a quenching tower are arranged, the HCl removal rate in the tail gas can be improved by a large margin under the premise of reducing the use amount of fresh desalinated water by a large margin, the HCl concentration of the tail gas is ensured to be controlled within 10 mg / Nm3, the flow of a produced condensate liquid is adjusted by controlling the temperature of the gas of a quenching tower outlet, the effect of tail gas cooling by the quenching tower is achieved, and no waste water is produced.

Owner:湖北瑞力源环保科技有限公司

Method for preparing calcium hydrophosphate through double-acidolysis of phosphorite

ActiveCN106044732ALess quantityHigh extraction rateCalcium/strontium/barium sulfatesPhosphorus compoundsSulfatePhosphorite

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

Spray roasting hydrochloric acid regeneration method and system for ferric oxide powder with high specific surface area

PendingCN110817804AIncrease BET valueConcentrated Acid Concentration DecreasesFerric oxidesPreparation from chloridesFlue gasPhysical chemistry

The invention provides a spray roasting hydrochloric acid regeneration method and system for ferric oxide powder with a high specific surface area. The method comprises the steps: a waste acid solution is heated and concentrated in a pre-concentrator and then is sprayed into a roasting furnace through a feeding pipeline of the roasting furnace; the generated roasting flue gas is subjected to subsequent regeneration treatment and purification treatment, the waste acid solution is divided into a first pipeline and a second pipeline which are independent before entering the preconcentrator, the waste acid solutions in the first pipeline and the second pipeline respectively enter the roasting furnace and the preconcentrator, and the waste acid solution entering the preconcentrator is heated and concentrated and then is mixed with the waste acid solution in the first pipeline, and then the mixed solution enters the roasting furnace. On the basis of not reducing the treatment capacity of a conventional spray roasting hydrochloric acid regeneration system and not increasing the energy consumption, the waste acid solution is divided into two paths to respectively enter the roasting furnaceand the pre-concentrator, and a certain amount of waste acid is added into the feeding pipeline of the roasting furnace, so that the concentration of the concentrated acid for firing in the roastingfurnace is remarkably reduced, and the purpose of increasing the BET value of the produced ferric oxide powder is achieved.

Owner:WISDRI ENG & RES INC LTD

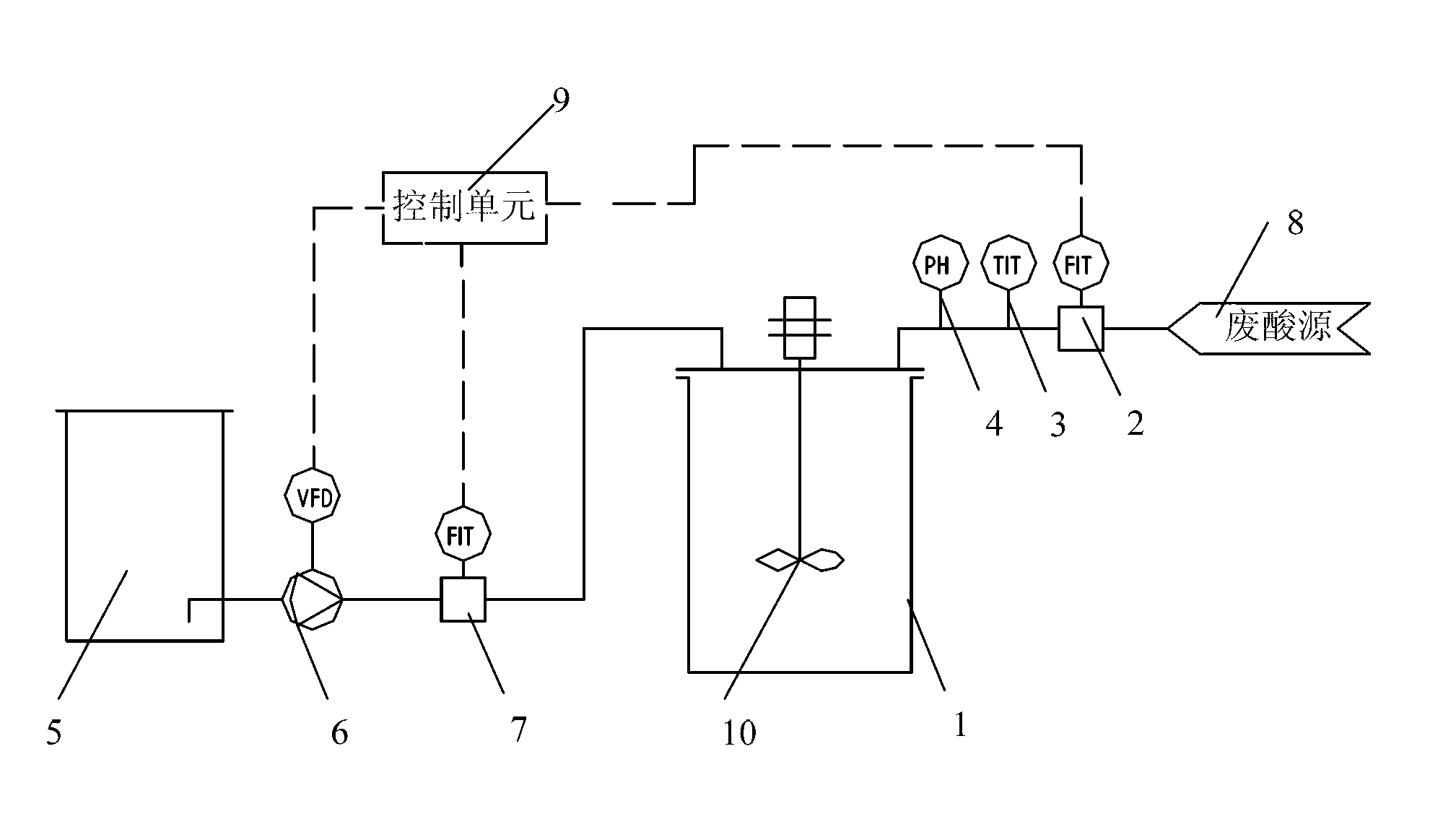

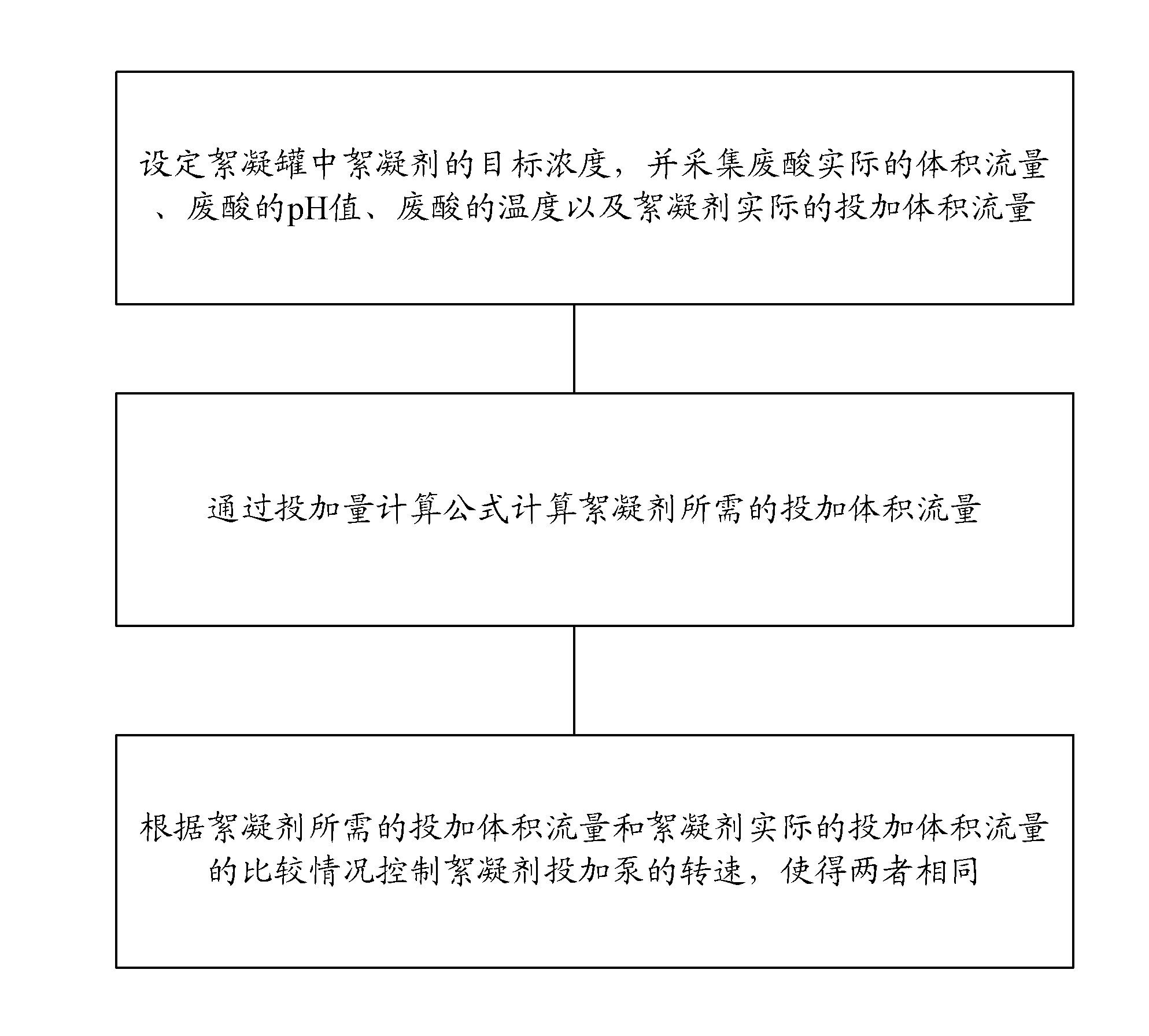

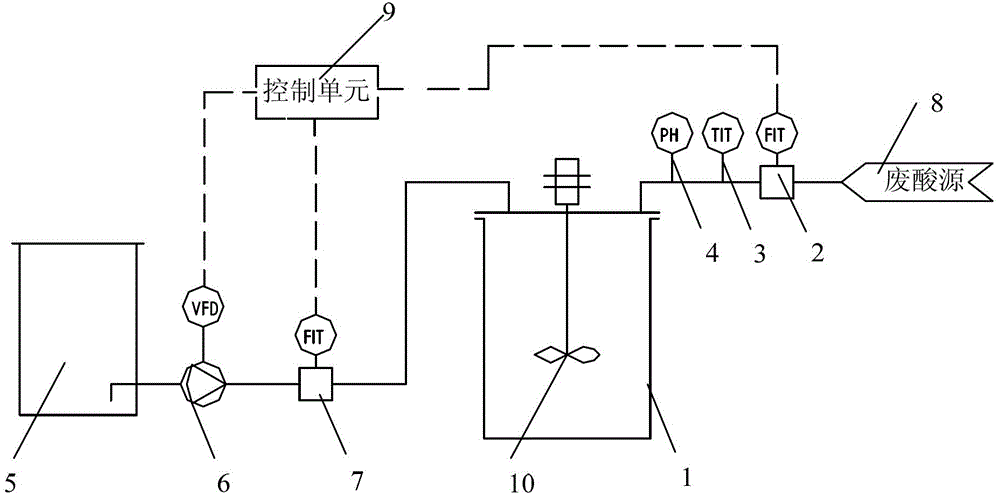

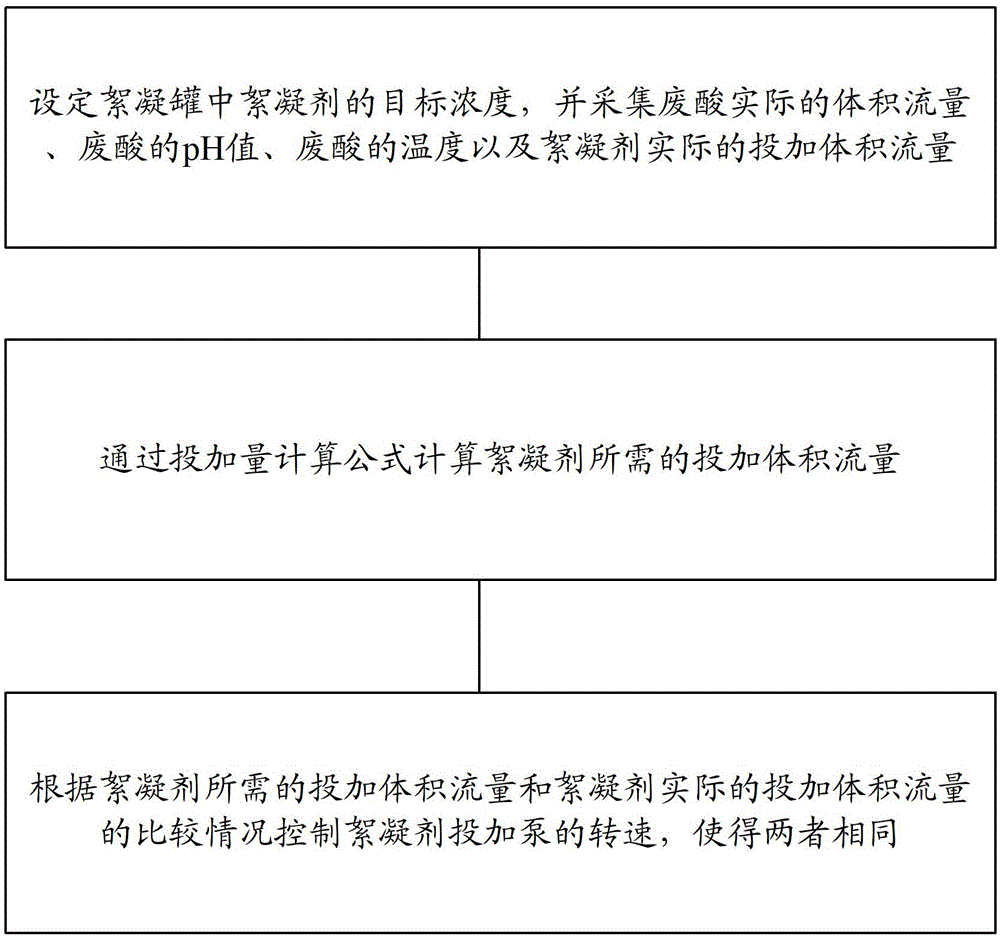

Automatic dosing method and device for hydrochloric acid regeneration desilication flocculant

ActiveCN103011082ARealize automatic controlRealize regulationChlorine/hydrogen-chloride purificationFlocculationAutomatic control

The invention provides an automatic dosing method and device for hydrochloric acid regeneration desilication flocculant. The method comprises the following steps: collecting the actual volume flow rate of waste acid, the pH value of the waste acid, the temperature of the waste acid and the actual dosing volume flow rate of flocculant; according to the target concentration of the flocculant in a flocculation tank and the collected actual volume flow rate of waste acid, pH value of the waste acid, temperature of the waste acid and actual dosing volume flow rate of the flocculant, calculating the required dosing volume flow rate of the flocculant; and then, comparing the required dosing volume flow rate of the flocculant and the actual dosing volume flow rate of the flocculant, controlling the rotation speed of a flocculant dosing pump to enable the two dosing volume flow rates to be the same if the two dosing volume flow rates are different, thereby realizing the automatic control and real-time regulation on the dosage of the flocculant. Thus, the problems of oversized or undersized flocculant dosage, unbalanced flocculant dosing concentration, untimely concentration regulation and the like caused by the existing manual intervention control are avoided.

Owner:白东 +1

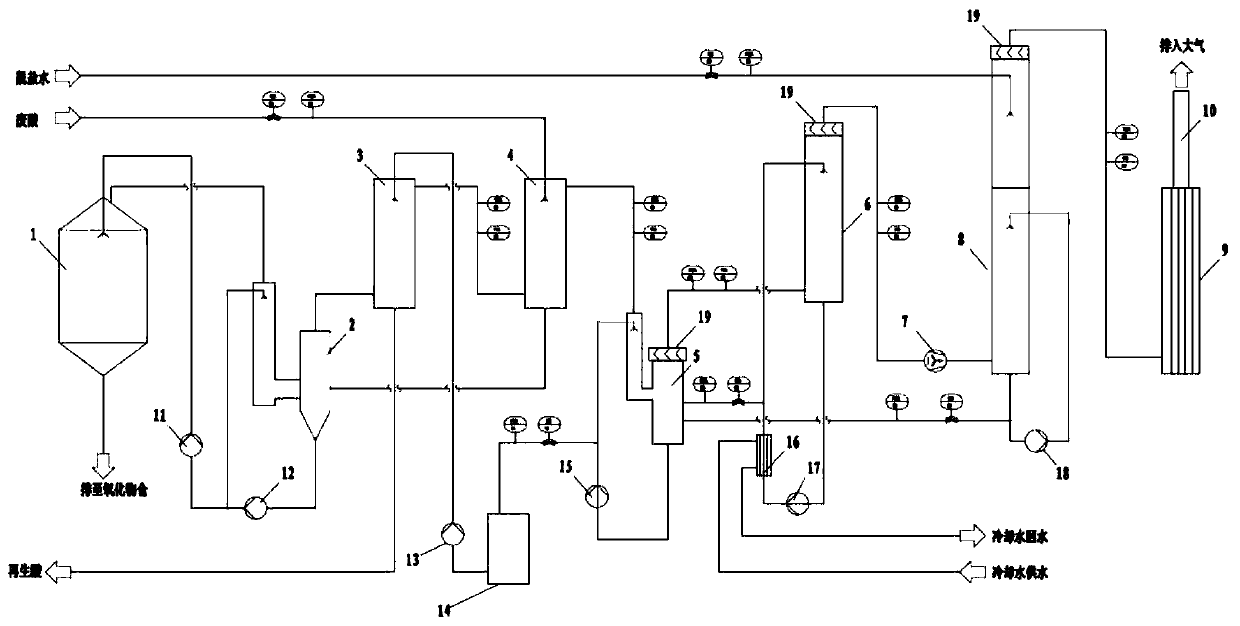

Hydrochloric acid regenerated flue gas emission system and emission method

PendingCN109718640AImprove corrosion resistanceImprove separation efficiencyCombination devicesUsing liquid separation agentAtmospheric airWater vapor

The invention relates to a hydrochloric acid regenerated flue gas emission system and an emission method and belongs to the technical field of regeneration of waste hydrochloric acid. The system and the method are used for solving the problem that the existing hydrochloric acid regeneration device is behindhand in process and cannot guarantee that the content of hydrogen chloride discharged in atmosphere is lower than 20mg / m<3> and the concentration of dust particulate matters is lower than 10mg / m<3>. The system comprises an absorption unit, a cooling unit, a separating unit, an air exhaust unit and a washing unit sequentially along a flue gas flow direction, wherein a monitoring device is arranged on the washing unit and is used for monitoring the content of pollutants in discharged fluegas; the absorption unit is used for absorbing hydrogen chloride from the flue gas to form regenerated hydrochloric acid; and the separating unit is used for separating dust particles with the particle size of 1 micron or more and liquid beads from the flue gas. According to the system, not only is the condition that the content of hydrogen chloride discharged in atmosphere from an iron-and-steelcold-rolling hydrochloric acid regeneration unit is lower than 20mg / m<3> and the concentration of dust particulate matters is lower than 10mg / m<3> achieved, but also the content of water vapor in theflue gas is greatly lowered; and the temperature of discharged flue gas is not above 60 DEG C.

Owner:NEW METALLURGY HI TECH GRP

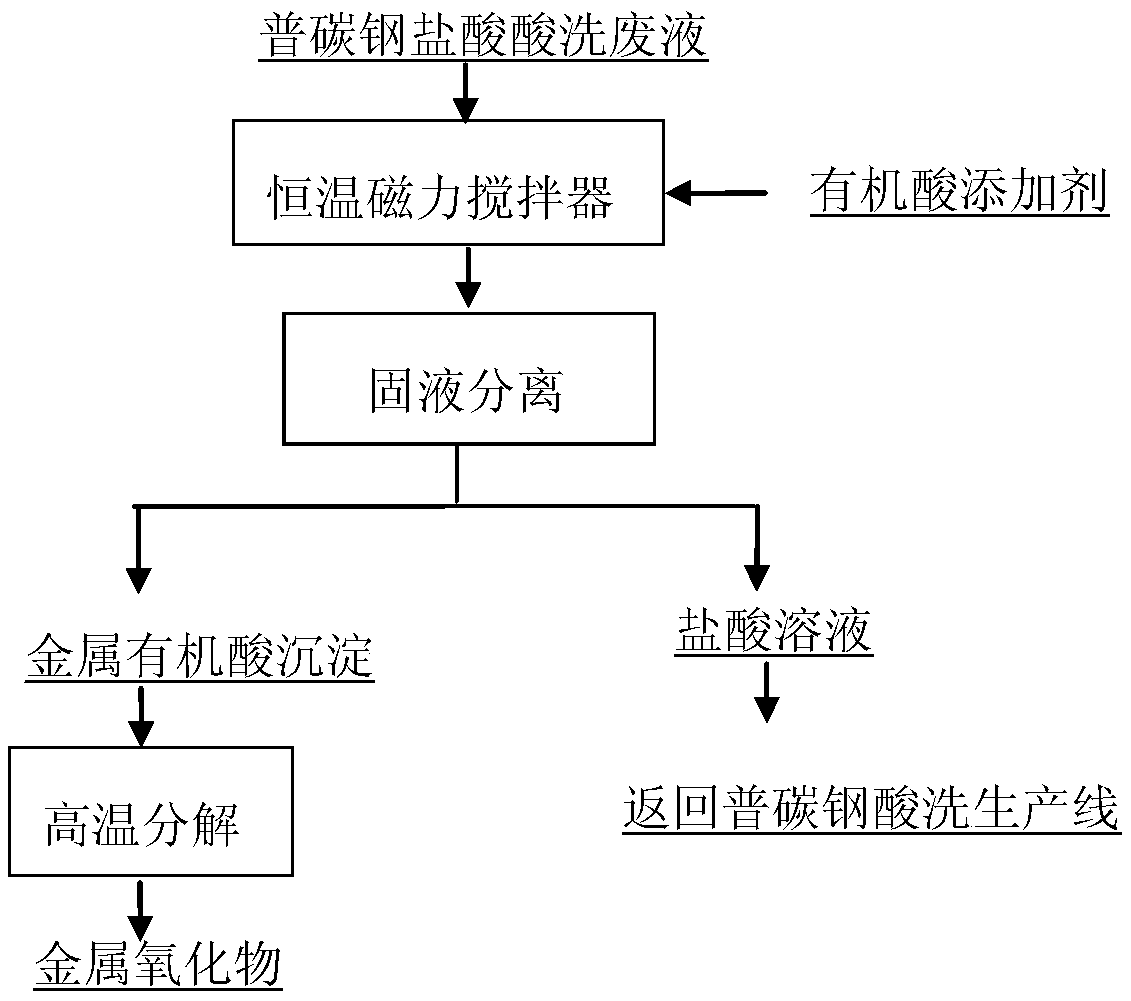

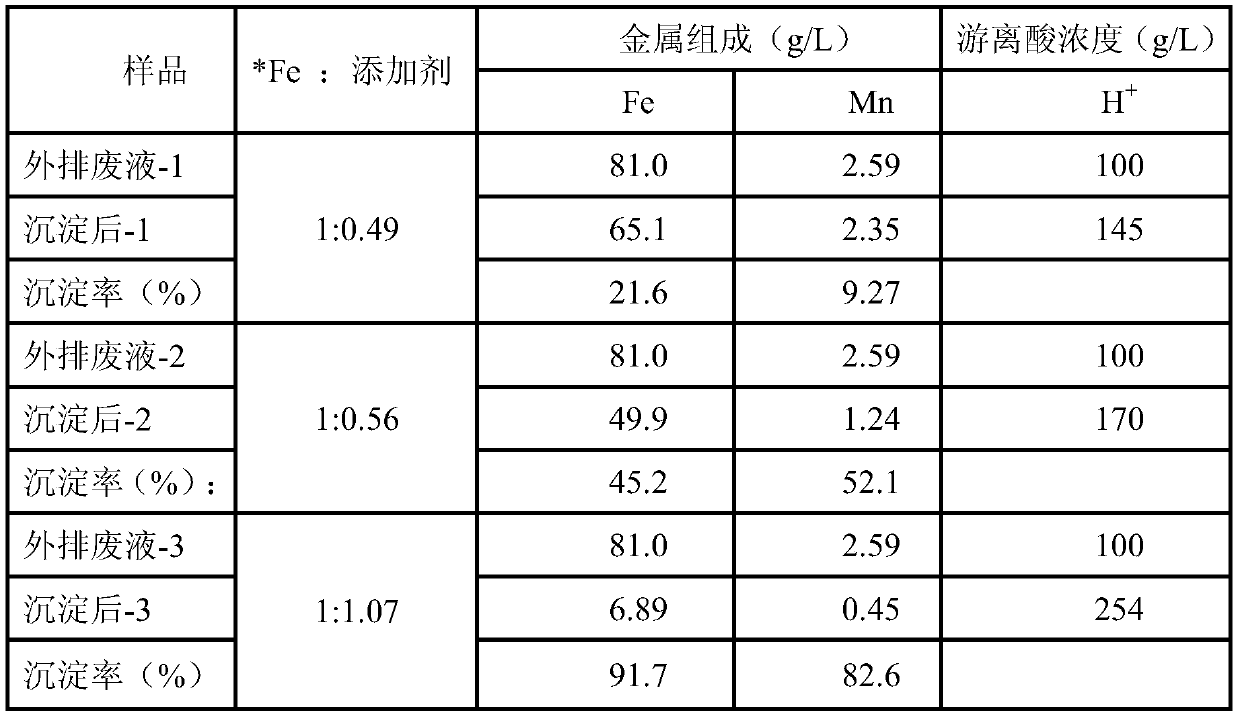

Rapid recovery treatment method of common carbon steel hydrochloric acid pickling waste liquid

InactiveCN110902872AEasy to handleShort processWater contaminantsWaste water treatment from metallurgical processMinor metalsTrace metal

The invention relates to a quick recovery treatment method of common carbon steel hydrochloric acid pickling waste liquid, and the method comprises the following steps: 1) adding a certain proportionof organic acid additive into pickling waste liquid containing a large amount of ferrous ions, and sufficiently stirring at constant temperature to obtain a solid-liquid mixture; 2) carrying out solid-liquid separation on the solid-liquid mixture by adopting a vacuum circulating water pump to obtain a metal organic acid precipitate of iron and other trace metal elements and a hydrochloric acid solution; 3) directly adding the hydrochloric acid solution into a common carbon steel washing section for cyclic utilization; and 4) performing high-temperature calcination and drying on the obtained metal organic acid salt in a muffle furnace to obtain the metal oxide. The method effectively solves the problems of high recovery cost, low concentration of recovered hydrochloric acid, easy generationof secondary pollution and the like in the existing hydrochloric acid waste liquid treatment technology, realizes hydrochloric acid regeneration cycle and metal oxide added high value, and has high environmental protection benefit and economic benefit.

Owner:郑州市拓邦环保科技有限责任公司

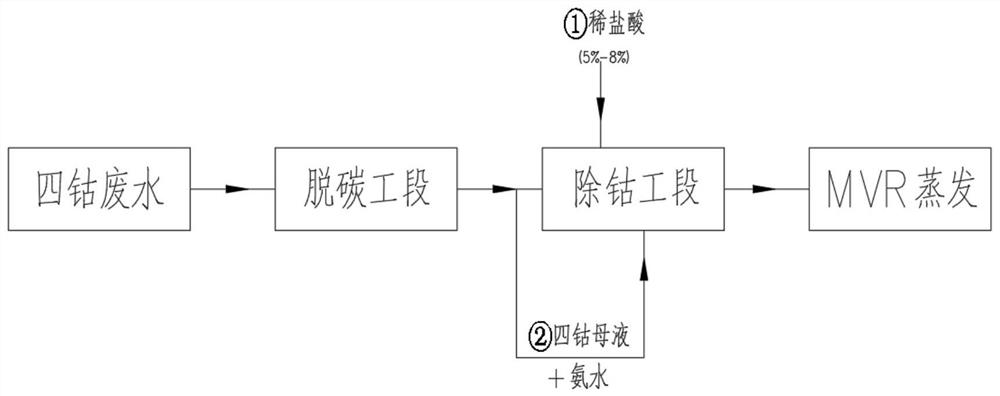

Regeneration process of cobalt-removing resin

ActiveCN112121873ASave investment costSave running costIon-exchanger regenerationWater contaminantsMaterials scienceChemical engineering

The invention relates to a regeneration process of cobalt-removing resin, after the cobalt-removing resin adsorbs decarburized tetracobalt wastewater to be saturated, the regeneration process is carried out on the cobalt-removing resin, the cobalt-removing resin is CH-90 divalent chelated cobalt-removing resin, and the ion form of the cobalt-removing resin is hydrogen type; the regeneration technology comprises the steps that hydrochloric acid is adopted for regeneration, after regeneration is completed, decarburized tetracobalt wastewater is adopted for flushing, and a certain amount of ammonia water is added to adjust the pH value. The ion form in the cobalt removal resin is a hydrogen form rather than a traditional sodium form directly adopted in the market at present, the regenerationliquid is regenerated by hydrochloric acid, the cobalt removal resin is completely suitable for the cobalt removal process of the tetracobalt wastewater, and other impurity ions are not introduced; the regenerated hydrogen-type resin is flushed by adopting the decarburized tetracobalt wastewater, the hydrogen-type resin is replaced by the ammonium-type resin, and the ammonia water is added to adjust the pH value back to the original pH value of the tetracobalt wastewater, so that the strong fluctuation of the pH value of the system is not caused in the next period of adsorption, the subsequentevaporation process can be quickly carried out, and the investment and the operation cost are saved.

Owner:昆山三一环保科技有限公司

Anion exchange resin recovery process applied to biological extraction

PendingCN113457750ARestore adsorption capacityReduce purchasesIon exchange beds cleaning/rinsingAlkali saltIon exchange

The invention discloses an anion exchange resin recovery process applied to biological extraction. The anion exchange resin recovery process comprises the following steps: sampling 400ml of invalid anion exchange resin for nucleotide separation, and loading into an ion exchange column; preparing 800ml of regenerant and storing in a storage tank; circularly soaking for 24 hours by using the regenerant in volume of 1-4 times that of the resin; after soaking, washing with water with the volume 4-8 times that of the resin, and regenerating with 1-2 mol / L HCL and 1-2 mol / L NaOH respectively; and performing static adsorption inspection on the adsorption effect of the regenerated resin. According to the invention, the use frequency of the anion exchange resin can be increased from 30 times to 100 times; according to the invention, the polluted resin is continuously used after being treated, so that the generation of solid waste is reduced; after the anion exchange resin is treated by the method, the resin cost can be reduced by 50% every year; common regeneration methods include acid regeneration, alkali regeneration, salt regeneration, alkali salt regeneration and the like, while alcohol regeneration and alcohol and hydrochloric acid regeneration are adopted in the method, so that the regeneration effect is remarkably improved.

Owner:NANTONG QIUZHIYOU BIOSCI & BIOTECH

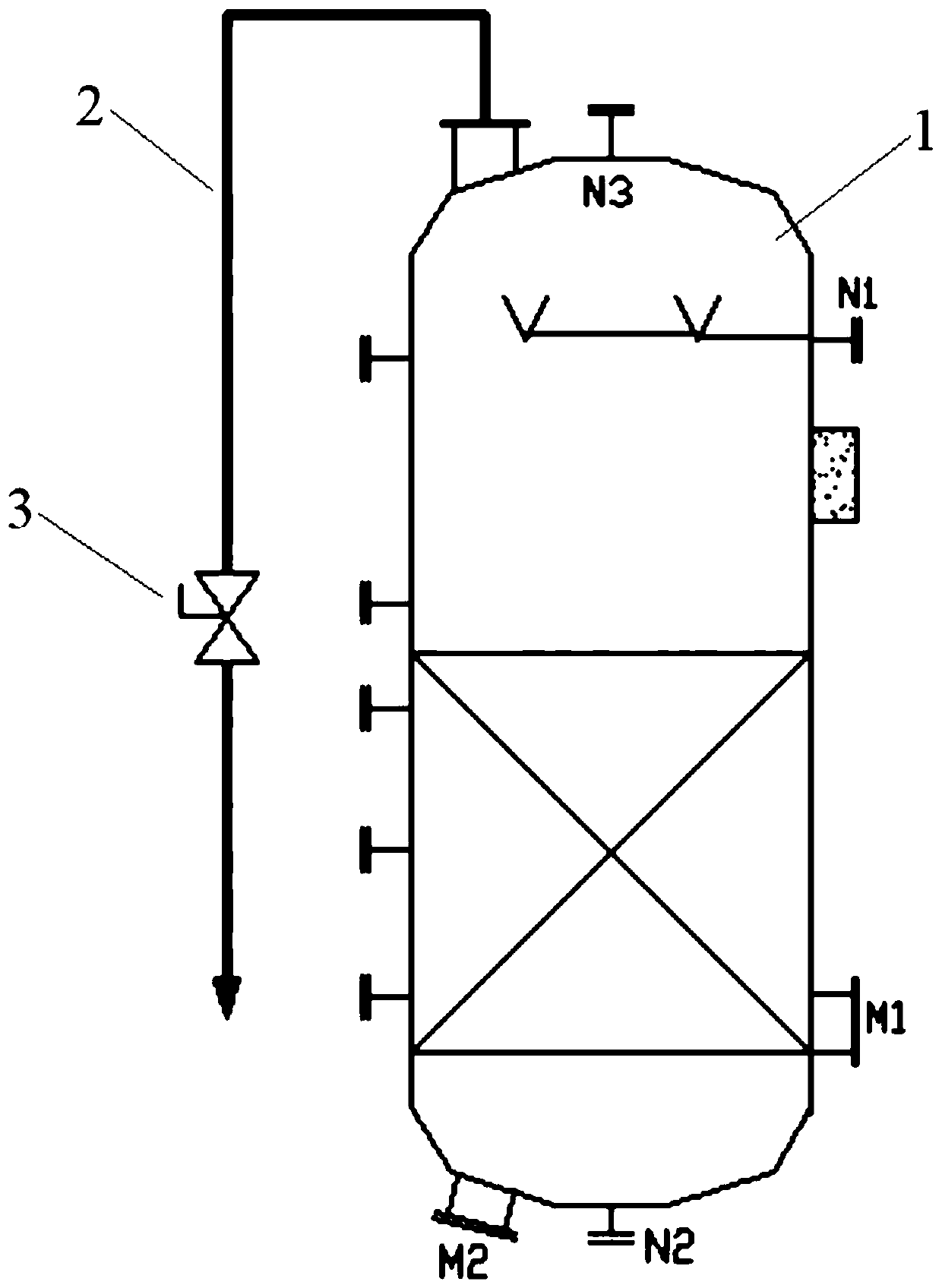

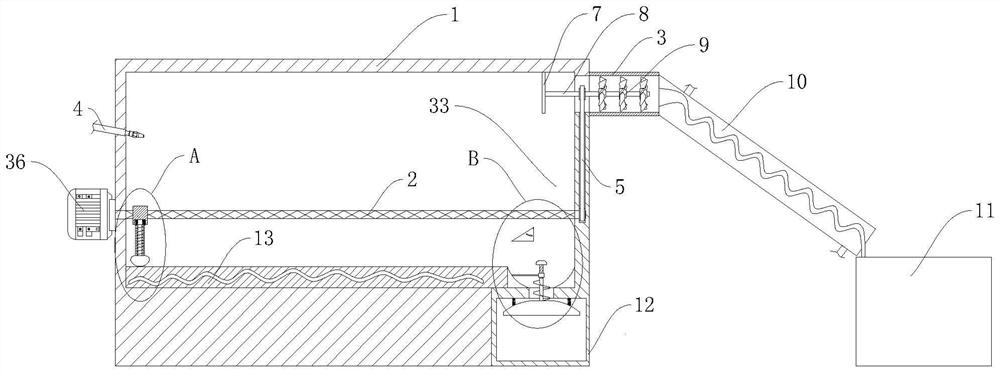

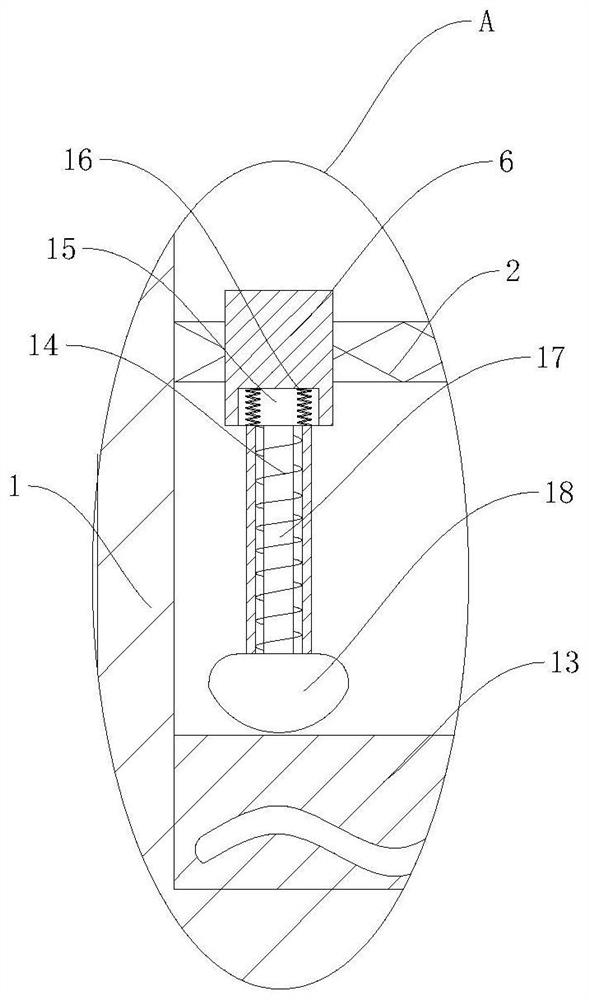

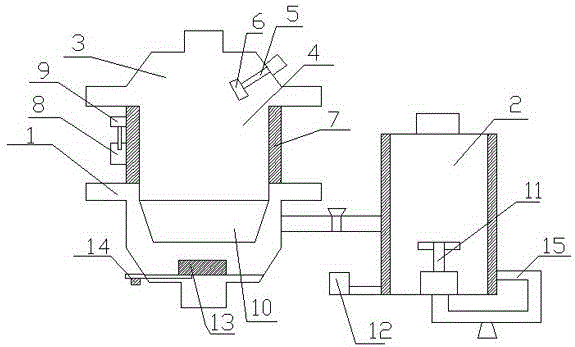

Concentrated hydrochloric acid recovery system for hydrochloric acid regeneration

PendingCN114277378ARemove in timeAffects the rate of recyclingChlorine/hydrogen-chloride purificationIron powderLiquid storage tank

The invention relates to the technical field of hydrochloric acid regeneration and recovery, in particular to a concentrated hydrochloric acid recovery system for hydrochloric acid regeneration, which comprises a box body, a spray head is fixedly connected to the position, close to the upper end, of the left side of the box body, an air outlet pipe is fixedly connected to the position, close to the upper end, of the right side of the box body, and a condensation pipe is fixedly connected to the right side of the air outlet pipe; a liquid storage tank is fixedly connected to the right side of the condensation pipe, a heating plate is fixedly connected to the inner surface of the lower end of the box body, an iron removing mechanism is arranged on the inner surface of the box body, and an iron collecting box is fixedly connected to the right side of the inner surface of the lower end of the box body; the iron removing mechanism comprises a supporting plate, a rotating rod, fan blades, a belt, a reciprocating lead screw, a lead screw nut, a sliding groove, a motor, a coil and an adsorption plate, iron powder generated on the surface of the heating plate is removed in time through the iron removing mechanism, and the situation that due to long-term accumulation of the iron powder during recycling, the working efficiency of the heating plate is reduced, and the hydrochloric acid recycling rate is affected is avoided; and the practicability of the device is improved.

Owner:王理想

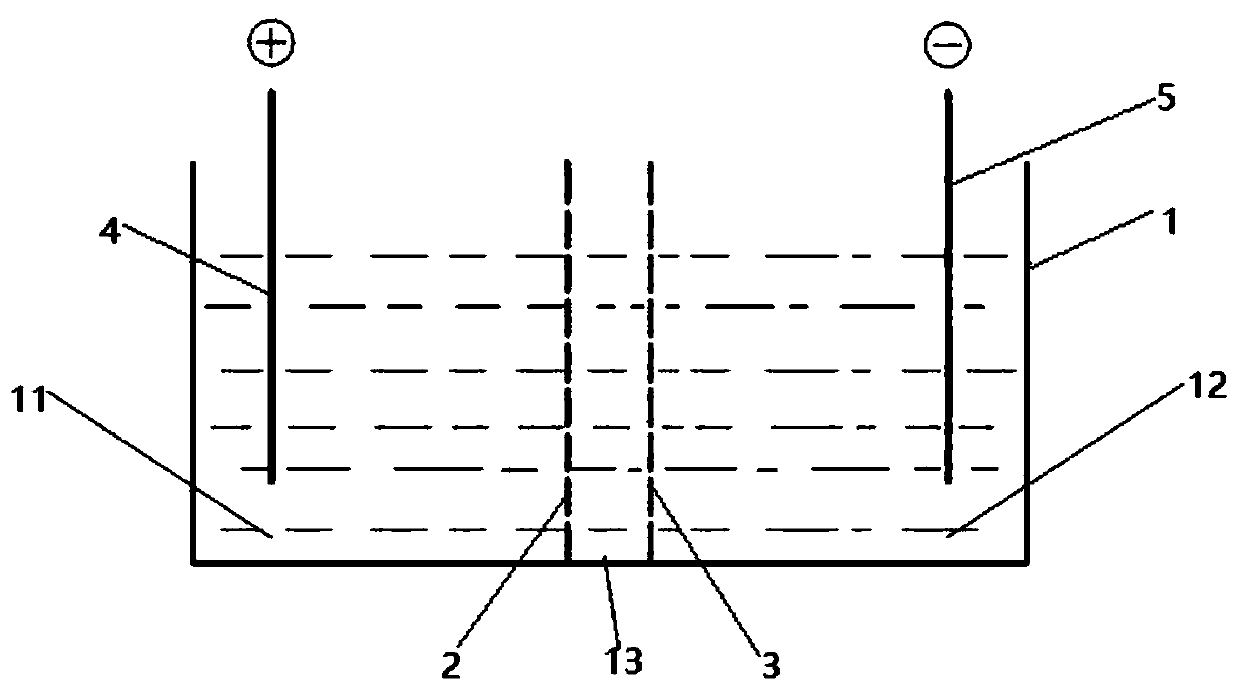

Method for electrolyzing circuit board acidic etching waste liquid

ActiveCN110408936AImprove current efficiencyWon't happenPhotography auxillary processesProcess efficiency improvementLiquid wasteElectrolysis

The invention discloses a method for electrolyzing a circuit board acidic etching waste liquid. The method comprises the following steps of adding an organic acid solution or a nitric acid solution which does not contain chloride ions and sulfur ions into an anode chamber; adding the circuit board acidic etching waste liquid to a cathode chamber and a middle separation chamber; applying a power source to an anode plate of the anode chamber and a cathode plate of the cathode chamber so as to carry out electrolysis; and carrying out hydrochloric acid regeneration in the middle separation chamber. Compared with the prior art, through the electrolysis method, anolyte does not generate chlorine in the electrolysis reaction process, so that the production cost of absorbing chlorine is reduced, and the environmental pollution caused by chlorine leakage can be avoided; the hydrochloric acid anode chamber regenerated in the middle separation chamber an the oxygen generated in the anode chamberare used for regenerating the etching waste liquid into an etching solution for recycling; in addition, after part of the anode liquid enters the middle chamber or the cathode chamber through a cationexchange membrane, the etching speed and the etching factor of the etching solution regenerated by the middle chamber are not reduced; and meanwhile, the waste liquid after electrolysis of the cathode chamber cannot pollute the environment.

Owner:HUIZHOU ZHENDING ENVIRONMENTAL PROTECTION TECH CO LTD

Novel concentrated hydrochloric acid recovering mechanism for hydrochloric acid regeneration

InactiveCN106145041AImprove concentrationRapid concentrationChlorine/hydrogen-chloride purificationBiochemical engineeringLiquid storage tank

A novel concentrated hydrochloric acid recovering mechanism for hydrochloric acid regeneration comprises a concentration device and a pre-concentration tank which are connected with each other, wherein a sealing cover is arranged on the concentration device; a liquid storage tank is arranged below the sealing cover; a sealing bottom is arranged at the lower part of the liquid storage tank; a hydrochloric acid inlet is formed in the liquid storage tank; a duct is arranged at the hydrochloric acid inlet; a nozzle is arranged below the duct; an anti-corrosion layer is arranged in the liquid storage tank and comprises a ceramic layer and a filling layer; the filling layer is filled with an acid-resistant material. The pre-concentration tank is arranged beside the concentration device, concentrated hydrochloric acid can be pretreated before treatment, impurities of recovered hydrochloric acid can be settled, the purity of hydrochloric acid can be improved, hydrochloric acid can enter the concentration device for further concentration conveniently, and the production efficiency of hydrochloric acid is improved.

Owner:瑞盈环保科技(扬州)有限公司

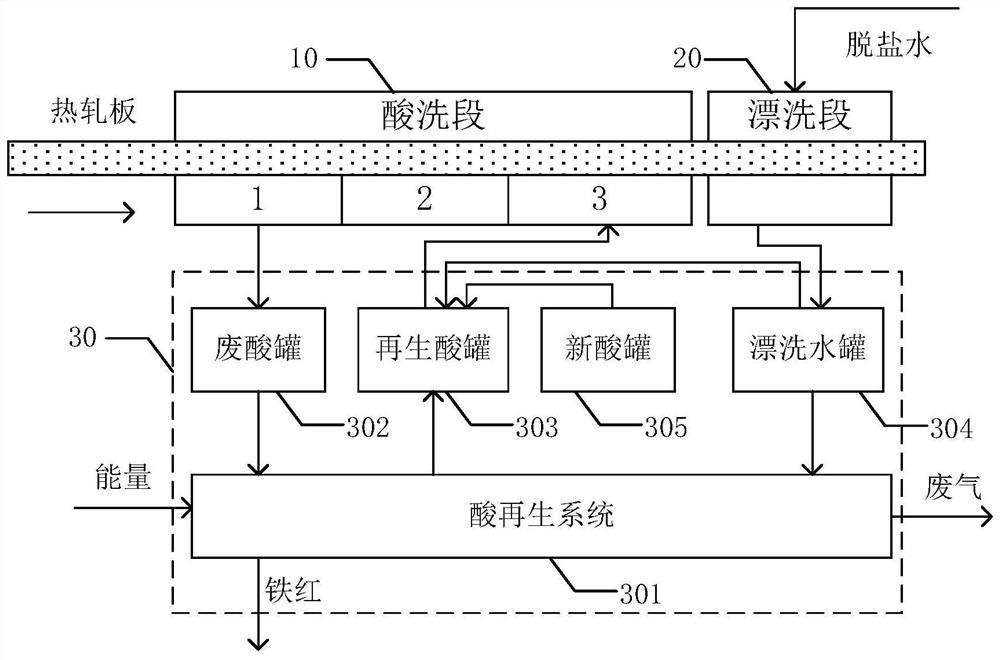

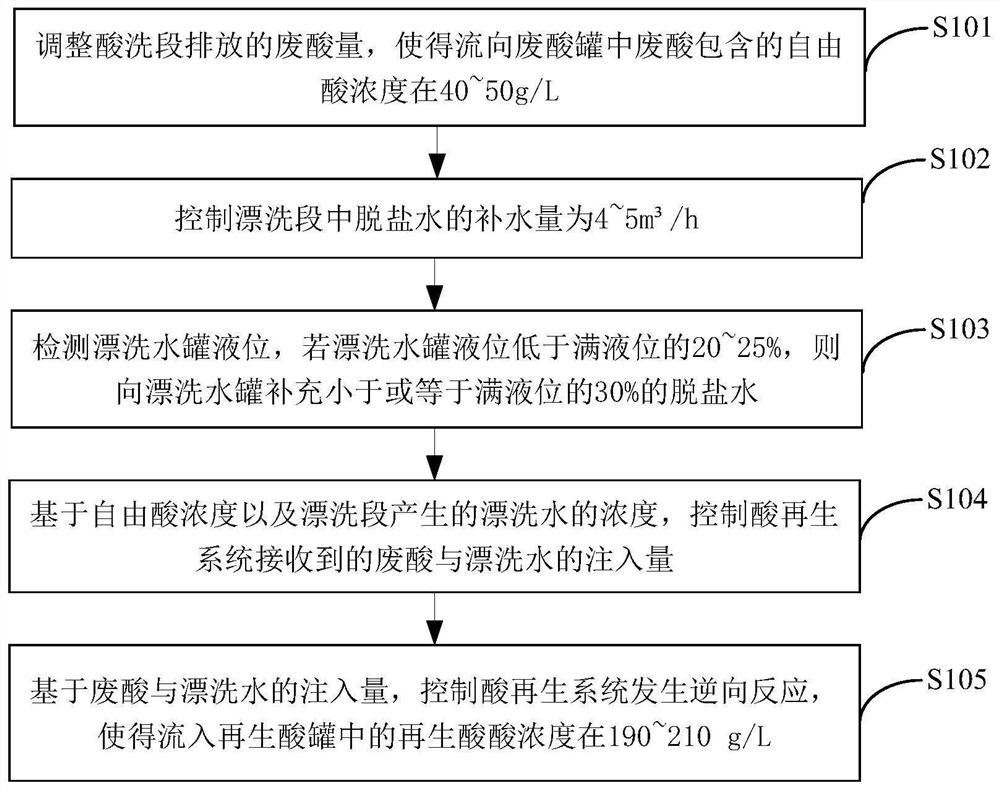

Pickling acid regeneration control method

The invention discloses a pickling acid regeneration control method, which is applied to a cold rolling system, and comprises the following steps: adjusting the amount of waste acid discharged in a pickling section, so that the concentration of free acid contained in the waste acid flowing to a waste acid tank is 40-50g / L; and the water supplementing amount of desalted water in the rinsing line is controlled to be 4-5 m<3> / h; detecting the liquid level of a rinsing water tank, and if the liquid level of the rinsing water tank is 20-25% lower than the full liquid level, supplementing desalted water with the amount smaller than or equal to 30% of the full liquid level to the rinsing water tank; based on the concentration of the free acid and the concentration of the rinsing water generated by the rinsing line, controlling the injection amount of the waste acid and the rinsing water received by the hydrochloric acid regeneration treatment system; based on the injection amount of the waste acid and the rinsing water, controlling the hydrochloric acid regeneration treatment system to perform reverse reaction to generate target gas, and conveying the target gas to a regeneration acid tank, so that the acid concentration of regeneration acid generated in the regeneration acid tank is 190-210 g / L. The method can effectively reduce the operation cost of acid pickling and acid regeneration.

Owner:BEIJING SHOUGANG COLD ROLLED SHEET

Automatic dosing method and device for hydrochloric acid regeneration desilication flocculant

ActiveCN103011082BThe dosage is easy to controlHigh precisionChlorine/hydrogen-chloride purificationFlocculationAutomatic control

The invention provides an automatic dosing method and device for hydrochloric acid regeneration desilication flocculant. The method comprises the following steps: collecting the actual volume flow rate of waste acid, the pH value of the waste acid, the temperature of the waste acid and the actual dosing volume flow rate of flocculant; according to the target concentration of the flocculant in a flocculation tank and the collected actual volume flow rate of waste acid, pH value of the waste acid, temperature of the waste acid and actual dosing volume flow rate of the flocculant, calculating the required dosing volume flow rate of the flocculant; and then, comparing the required dosing volume flow rate of the flocculant and the actual dosing volume flow rate of the flocculant, controlling the rotation speed of a flocculant dosing pump to enable the two dosing volume flow rates to be the same if the two dosing volume flow rates are different, thereby realizing the automatic control and real-time regulation on the dosage of the flocculant. Thus, the problems of oversized or undersized flocculant dosage, unbalanced flocculant dosing concentration, untimely concentration regulation and the like caused by the existing manual intervention control are avoided.

Owner:白东 +1

A kind of preparation method of silica sol for acrylonitrile catalyst

The invention discloses a preparation method of ludox for an acrylonitrile catalyst. The method comprises: adding sulfuric acid aqueous solution into industrial sodium silicate aqueous solution with a silicon dioxide content of 3-5 wt percent until pH is 9.0-9.5, heating up to 90-95 DEG C, and then keeping warm for 1-2 hours to form ludox base solution; adding water into industrial sodium silicate with a modulus of 3.0-3.3, preparing aqueous solution with a silicon dioxide content of 3-5 wt percent, suspending cation exchange resin by using deionized water, then adding sodium silicate and controlling outlet pH to be 2-3 after ion exchange to obtain silicic acid, adding the silicic acid into the prepared ludox base solution at a speed of 100-200ml / min, keeping pH to be 9-9.5, keeping warm for 1-2 hours under the temperature of 90-95 DEG C, and then cooling to normal temperature; performing ion exchange on a product by using strong-acidity cation exchange resin regenerated by hydrochloric acid, meanwhile keeping pH to be 1-2, and after exchange, adding ammonium hydroxide and adjusting pH to be 9-9.5; finally adding a dispersing agent into the prepared ludox, and performing ultrafiltration and concentration to obtain the ludox. The prepared ludox has the mean grain size of 20-25nm, the sodium ion content less than 0.05 percent, the concentration of 40-50 percent and the viscosity less than 20cps.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com