Method and device for recycling useful substances from waste hydrochloric acid liquor

A technology for acid recovery and waste hydrochloric acid, applied in the directions of ferric sulfate, chlorine/hydrogen chloride, etc., can solve the problems of large investment and small income in recycling waste acid, achieve small investment in equipment, improve economic value, and solve the difficulty of recycling and processing waste acid. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

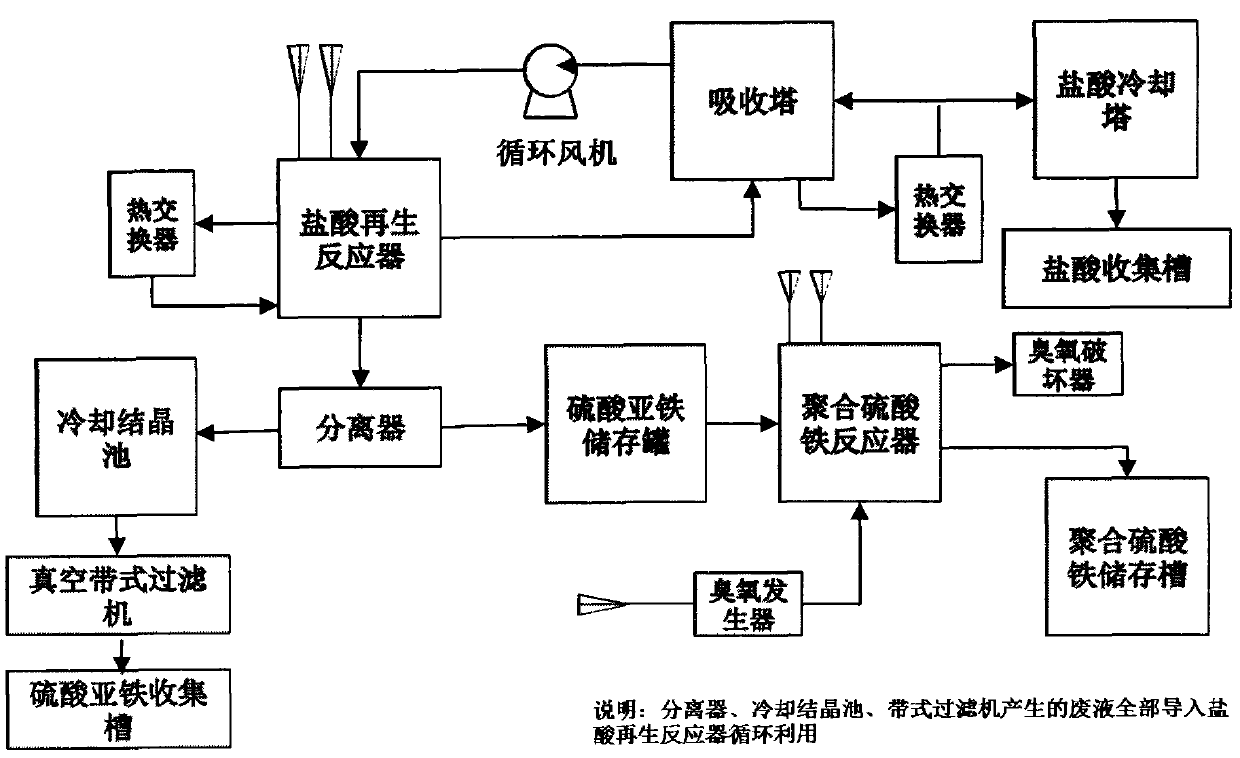

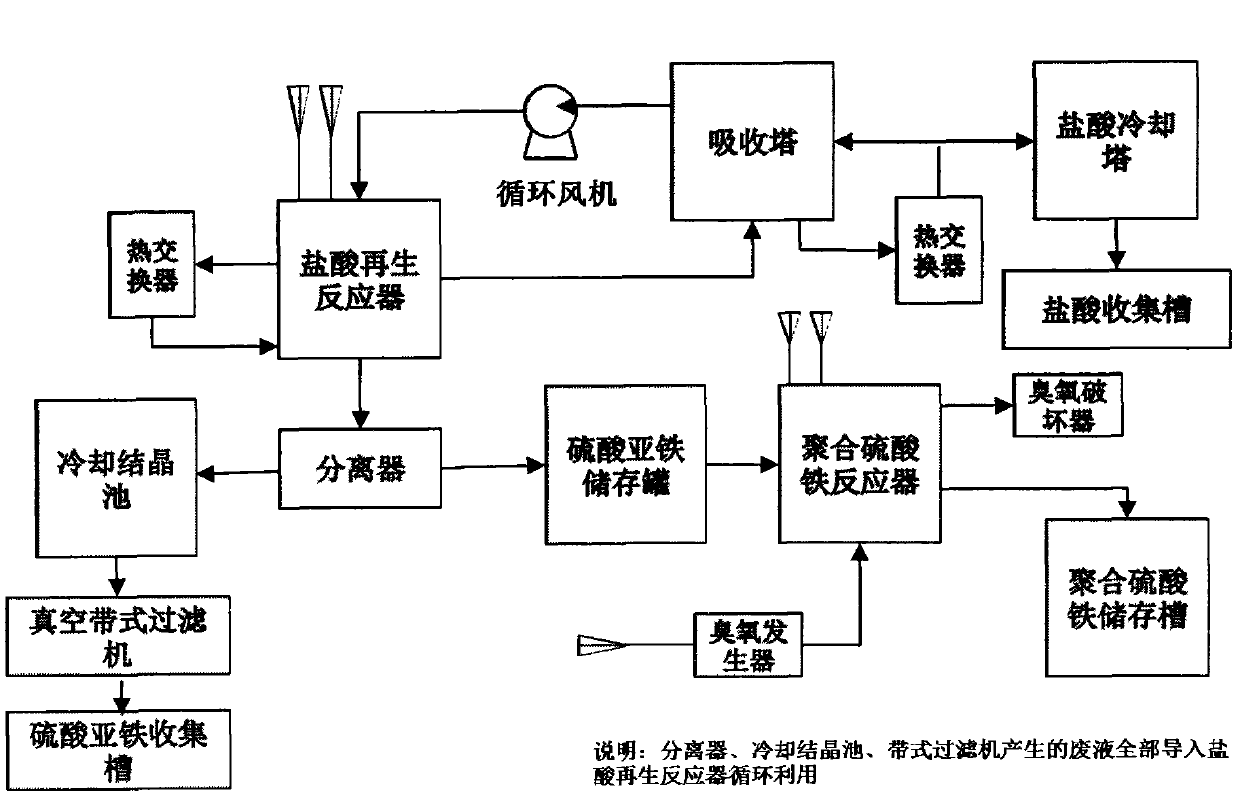

[0025] Put 11.7Kg of waste acid containing 11% iron and 5% hydrochloric acid into the hydrochloric acid regeneration reactor every hour, and put 2.3kg of 98% concentrated sulfuric acid into the hydrochloric acid regeneration reactor at the same time. After fully reacting, the acid vapor is brought into the absorption tower by the air flow. Reclaim 11.3Kg of 20% concentration hydrochloric acid; the ferrous sulfate and sulfuric acid raffinate mixture in the hydrochloric acid regeneration reactor obtains ferrous sulfate heptahydrate containing 19.8% iron after being filtered and dried by a separator, a cooling crystallization tank and a vacuum belt filter 6.39Kg.

Embodiment 2

[0027] Put 11.7Kg of waste acid containing 11% iron and 5% hydrochloric acid into the hydrochloric acid regeneration reactor every hour, and put 2.3kg of 98% concentrated sulfuric acid into the hydrochloric acid regeneration reactor at the same time. After fully reacting, the acid vapor is brought into the absorption tower by the air flow. Reclaim 11.3Kg of 20% concentration hydrochloric acid; Ferrous sulfate and sulfuric acid raffinate mixture in the hydrochloric acid regeneration reactor enter the ferrous sulfate storage tank after the separator, then ferrous sulfate 3.48Kg, concentrated sulfuric acid 0.34Kg, sodium chlorate 0.10 Kg, 0.04Kg of potassium permanganate, and 1.09 L of water are put into a polyferric sulfate reactor, and ozone is fully reacted under normal temperature and pressure for 30 minutes to obtain a polyferric sulfate containing 13.2% iron and a basicity of 14.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com