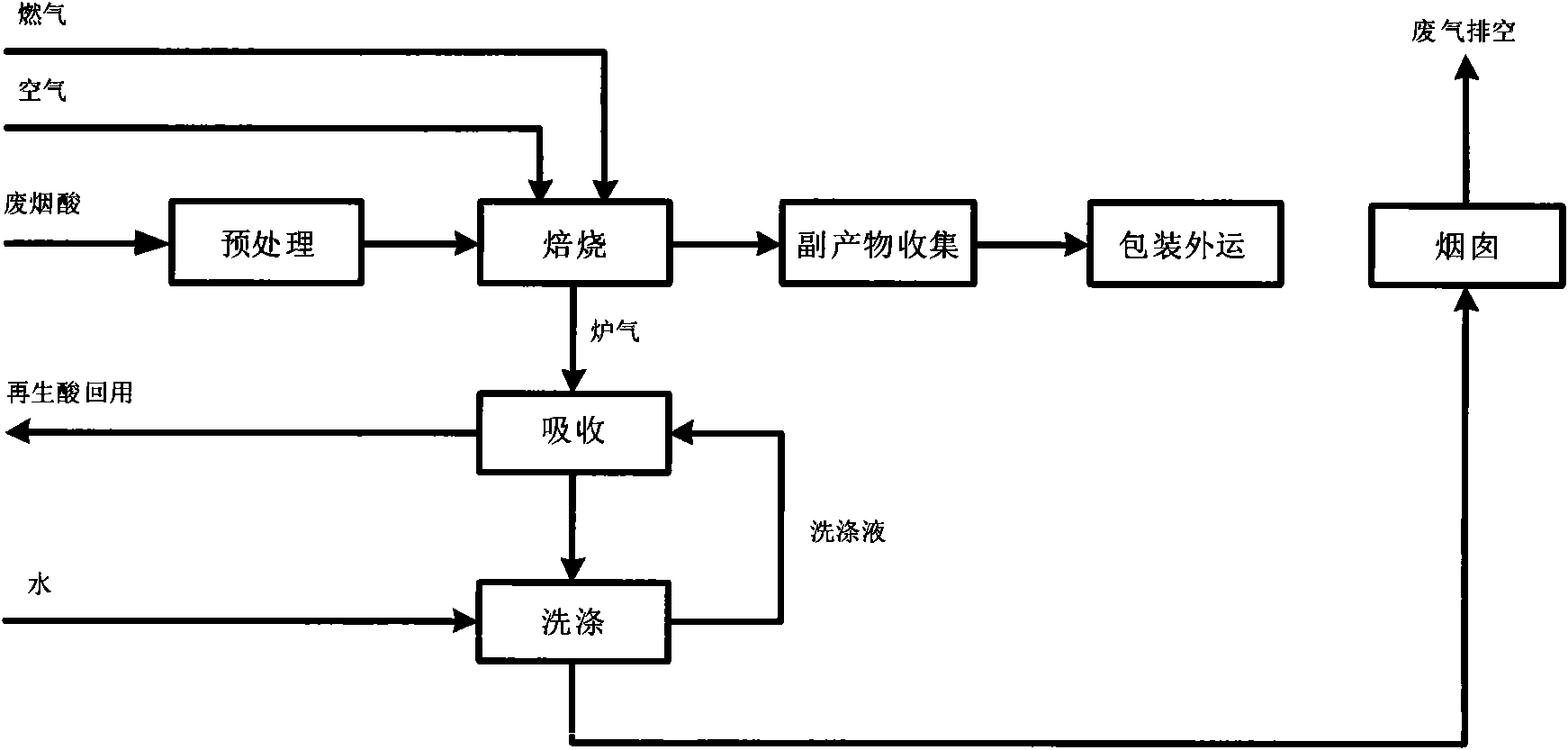

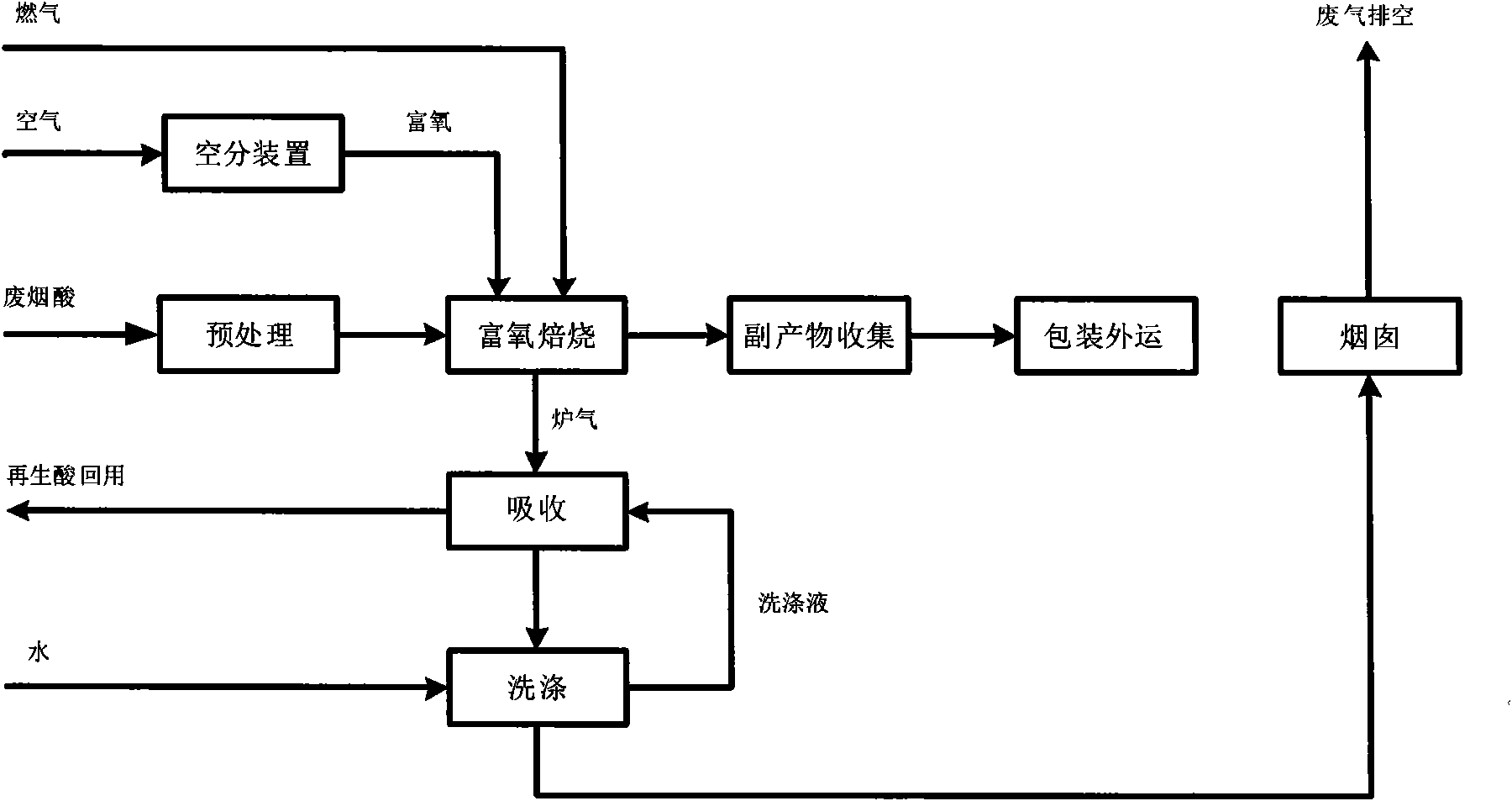

Method for regeneration of waste hydrochloric acid by oxygen enriched roasting

A technology of oxygen-enriched roasting and waste hydrochloric acid, applied in chlorine/hydrogen chloride purification, chlorine/hydrogen chloride and other directions, can solve the problems of increasing roaster gas volume, increasing load, restricting processing capacity, etc., achieving high waste acid processing capacity, improving The effect of processing capacity and convenient expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The waste hydrochloric acid solution formed after pickling of steel plates or leaching of non-ferrous metals enters the roasting furnace after pretreatment such as filtration and concentration. At the same time, the air separation device produces oxygen-enriched oxygen with an oxygen content of 22% to 95%. Using this oxygen-enriched gas as a combustion-supporting gas, the waste acid liquid is roasted in the roaster with oxygen-enriched, and the solid by-products obtained from the roasting are collected and packaged. Shipping sales. The furnace gas formed after roasting is rich in HCl, and after being absorbed by the washing liquid from the washing process, regenerated hydrochloric acid is generated and reused. After the absorption process, the furnace gas is washed with water to remove residual acidic substances. The cleaned furnace gas is discharged through the chimney after washing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com