Method for electrolyzing circuit board acidic etching waste liquid

A technology for acid etching waste liquid and circuit board, applied in the field of electrolysis, can solve the problems of reducing the etching speed of the etching waste liquid, polluting the environment by the waste liquid, and generating environmental loads, etc., so as to increase the cathode current efficiency, avoid environmental pollution, and reduce regeneration costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

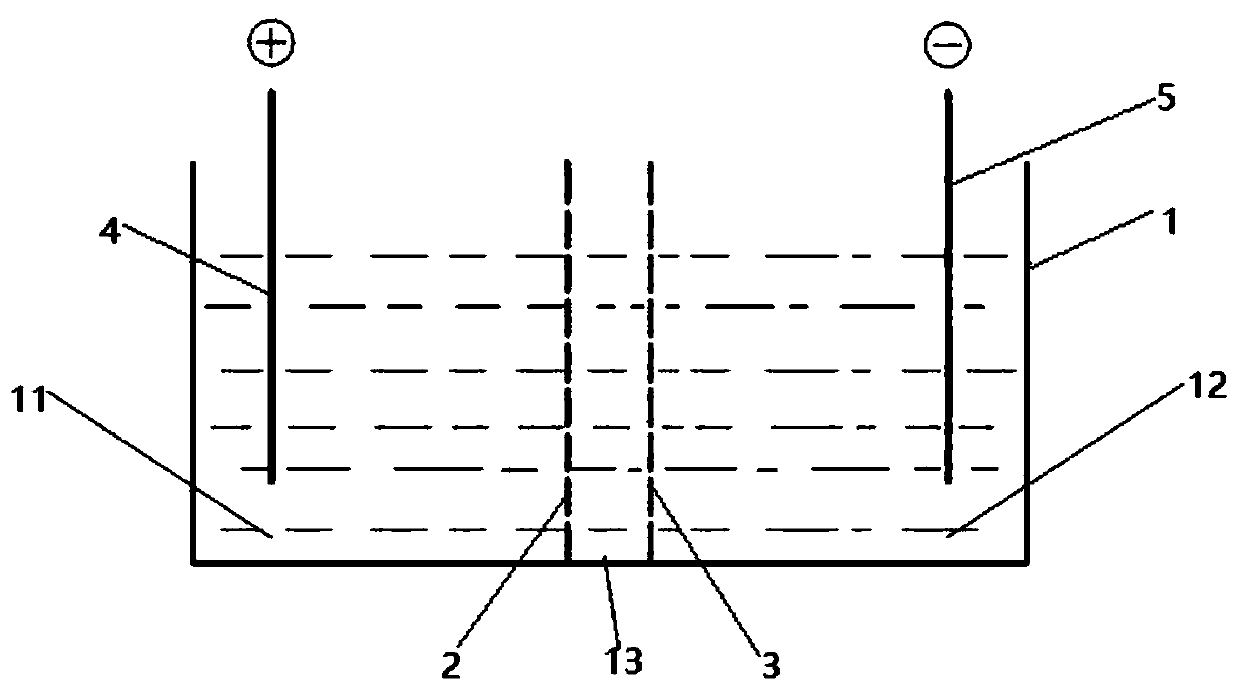

[0054] Example 1, the cathode and anode are separated by fluorine-containing cation exchange membrane and anion exchange membrane, and the nitric acid is 8% by concentration weight ratio as the anolyte, and the catholyte consists of 255 grams per liter of chloride ion, 135 grams per liter of Cu 2+ , composed of 70 g / L hydrochloric acid, the concentration of chloride ions in the catholyte remains unchanged when the direct current is applied for one hour, Cu 2+ The concentration dropped to 95.32 g / L and the concentration of hydrochloric acid rose to 95.30 g / L.

example 2

[0055] Example 2, the anode and cathode are separated by fluorine-containing cation exchange membrane and anion exchange membrane, 10% nitric acid is used as the anolyte, and the catholyte is composed of 263 g / liter of chloride ion, 122 g / liter of Cu 2+ , composed of 65 g / L hydrochloric acid, through direct current for one hour, the catholyte chlorine ion concentration remains unchanged, Cu 2+ The concentration dropped to 95.05 g / l and the concentration of hydrochloric acid rose to 95.65 g / l.

example 3

[0056] Example 3, the anode and cathode are separated by fluorine-containing cation exchange membrane and anion exchange membrane, 12% nitric acid is used as the anolyte, and the catholyte is composed of 279 grams per liter of chloride ion and 133 grams per liter of Cu 2+ , composed of 63 g / L hydrochloric acid, through direct current for one hour, the catholyte chloride ion concentration remains unchanged, Cu 2+ The concentration dropped to 94.90 g / l and the concentration of hydrochloric acid rose to 95.78 g / l.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com