Rapid recovery treatment method of common carbon steel hydrochloric acid pickling waste liquid

A pickling waste liquid recovery treatment technology, applied in metallurgical wastewater treatment, precipitation treatment, water/sewage treatment, etc., can solve the problems of secondary pollution, low concentration of recovered hydrochloric acid, high recovery cost, etc., to reduce treatment costs, solid The effect of high purity and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

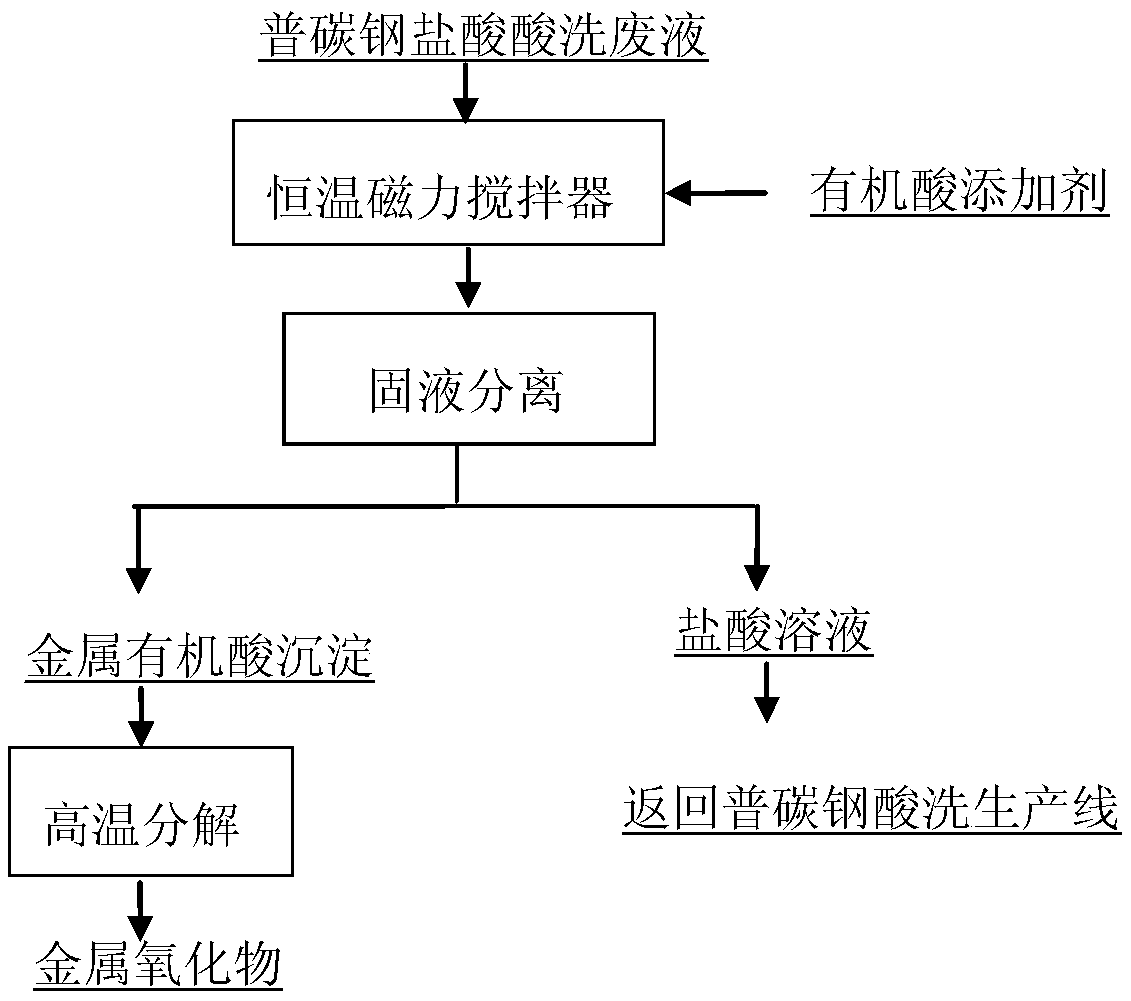

Method used

Image

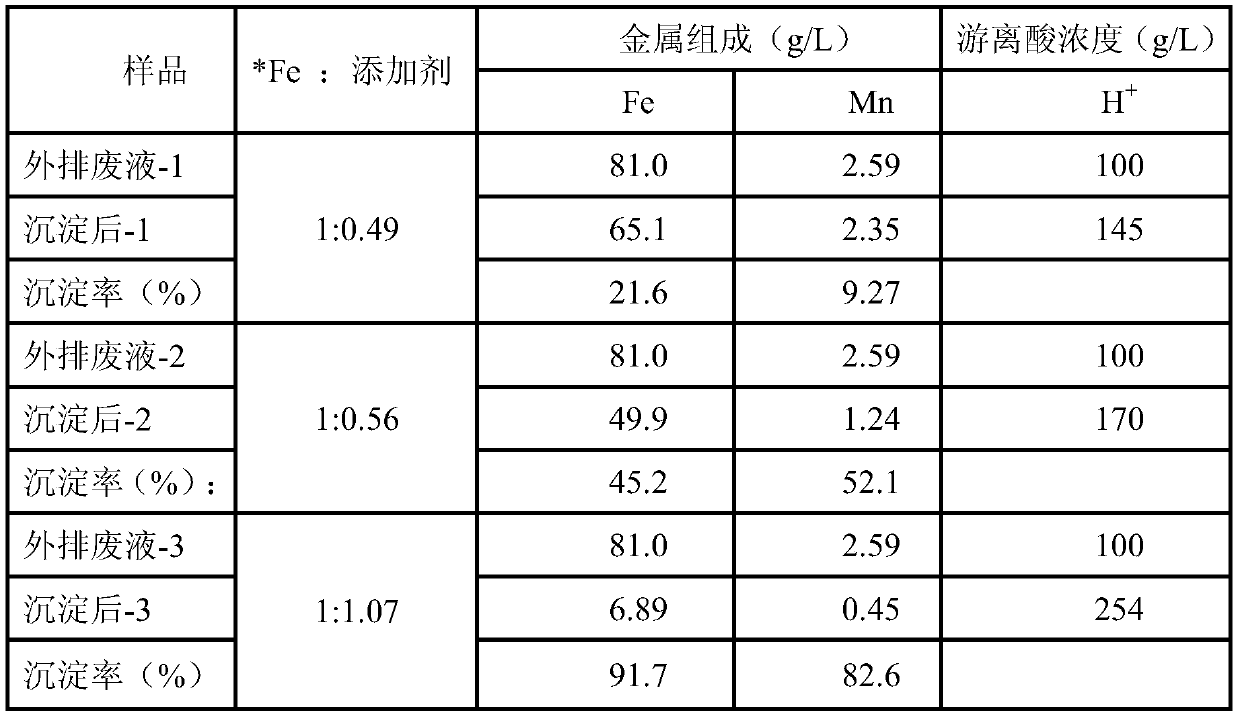

Examples

Embodiment 1

[0033] A kind of rapid recovery processing method of ordinary carbon steel hydrochloric acid pickling waste liquid, it is characterized in that: comprise the following steps:

[0034] 1) Add 500mL of pickling waste liquid containing 40g / L of ferrous iron and 150g / L of hydrochloric acid into a beaker, and place it in a constant temperature magnetic stirrer;

[0035] 2) Add 36 g of solid succinic acid to the pickling waste liquid in step 1), set the temperature at 30° C., and stir the pickling waste liquid added with succinic acid at a constant temperature; the stirring reaction time is 10 minutes to obtain ferrous succinate white precipitate mixture;

[0036] 3) adopting vacuum type circulating water pump to carry out solid-liquid separation to the ferrous succinate white precipitation mixture that step 2) obtains, obtain ferrous succinate precipitate and hydrochloric acid solution respectively;

[0037] 4) The hydrochloric acid solution obtained in step 3) is 226g / L after tes...

Embodiment 2

[0039] Embodiment 2: a kind of rapid recovery processing method of ordinary carbon steel hydrochloric acid pickling waste liquor, comprises the following steps:

[0040] 1) Add 500mL of pickling waste liquid containing 76g / L of ferrous iron and 121g / L of hydrochloric acid into a beaker, and place it in a constant temperature magnetic stirrer;

[0041] 2) Add 85.5 g of solid oxalic acid dihydrate to the waste pickling liquid in step 1), set the temperature at 40° C., and stir the waste pickling liquid with oxalic acid dihydrate at a constant temperature; the stirring reaction time is 30 minutes to obtain oxalic acid Ferrous yellow precipitate mixture;

[0042] 3) Carry out solid-liquid separation to the mixture of the ferrous oxalate yellow precipitate that step 2) obtains, obtain ferrous oxalate yellow precipitate and hydrochloric acid solution respectively;

[0043] 4) The hydrochloric acid solution obtained in step 3) is 226g / L after testing the concentration of free acid i...

Embodiment 3

[0046] A kind of rapid recovery treatment method of common carbon steel hydrochloric acid pickling waste liquor, comprises the following steps:

[0047] 1) Add 500 mL of pickling waste liquid containing 30 g / L of ferrous iron and 180 g / L of hydrochloric acid into a beaker, and place it in a constant temperature magnetic stirrer;

[0048] 2) Add 22 g of dihydrate oxalic acid liquid to the pickling waste liquid in step 1), set the temperature at 50° C., and stir the pickling waste liquid added with dihydrate oxalic acid at a constant temperature; the stirring reaction time is 60 minutes to obtain oxalic acid Iron yellow precipitation mixture;

[0049] 3) Carry out solid-liquid separation to the mixture of the ferrous oxalate yellow precipitate that step 2) obtains, obtain ferrous oxalate yellow precipitate and hydrochloric acid solution respectively;

[0050] 4) The hydrochloric acid solution obtained in step 3) is 226g / L after testing the concentration of free acid in the filtra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com