Method for separating platinum palladium iraurita

A technology for iridium, platinum and palladium, applied in the field of separation of platinum, palladium, iridium, can solve the problems of difficulty in stripping, high cost, troublesome operation, etc., and achieves the effects of wide application range, high recovery rate and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

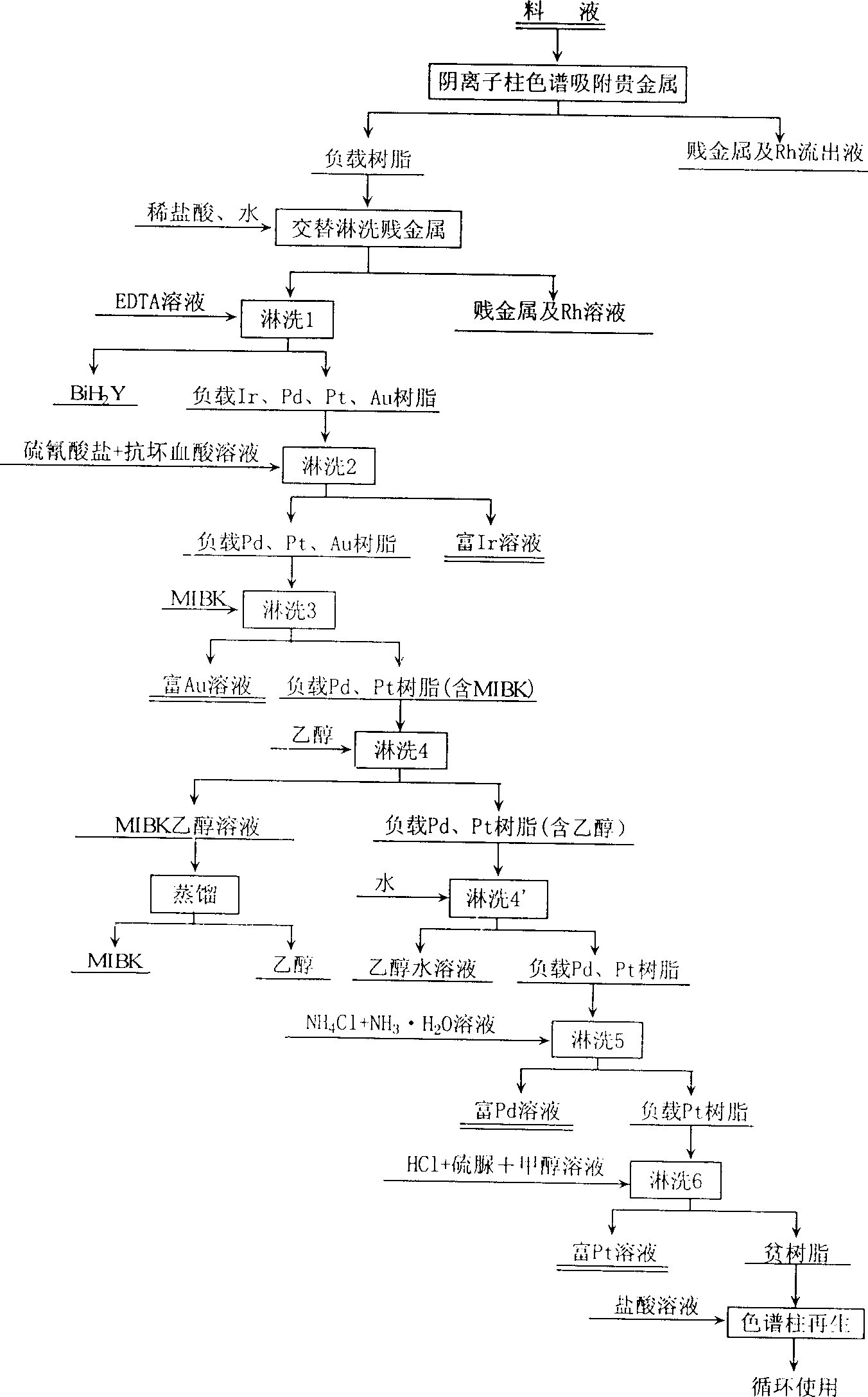

Method used

Image

Examples

Embodiment 1

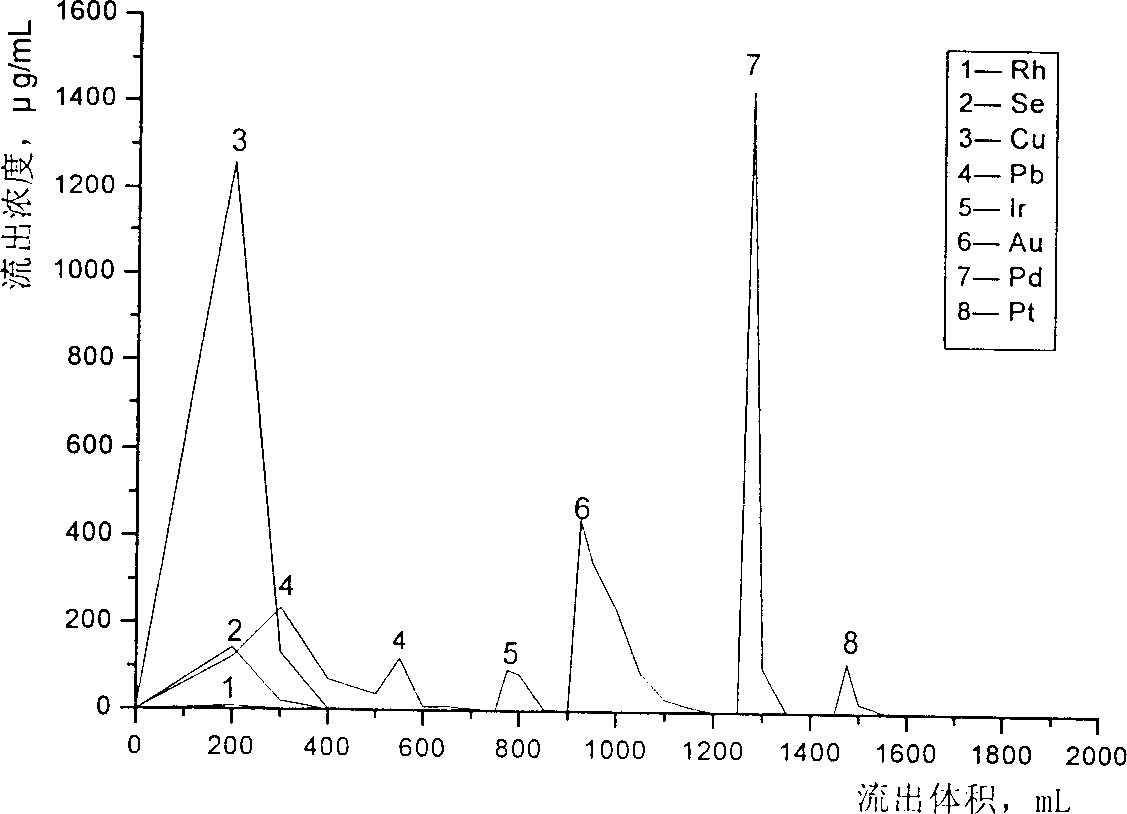

[0029] Platinum palladium concentrate separation

[0030]Platinum-palladium concentrate contains higher palladium, gold and platinum, and the test is carried out with samples containing palladium 38009g / t, gold 37611g / t and platinum 3821g / t. In the test, the processing capacity of the concentrate was 1g. Due to the low content of rhodium, iridium, cobalt, nickel, and zinc, in order to investigate the separation effect of the method on noble, base metals and precious metals, 5mg iridium, 2mg Rhodium, 5mg cobalt, 5mg nickel, 5mg zinc; the chromatographic column is φ11mm×150mm; the injection volume is 200mL, the total concentration of hydrochloric acid in the medium is 0.5mol / L, and the linear flow rate of the injection mobile phase is 10cm / min; the first group of eluent Be 300mL 0.2mol / L hydrochloric acid, 50mL water, 50mL0.1mol / L hydrochloric acid, 50mL water, 100mL0.05mol / L HCl+1g / L EDTA, mobile phase linear flow velocity 5cm / min; The second group eluent is 150mL0. 5mol / L KSC...

Embodiment 2

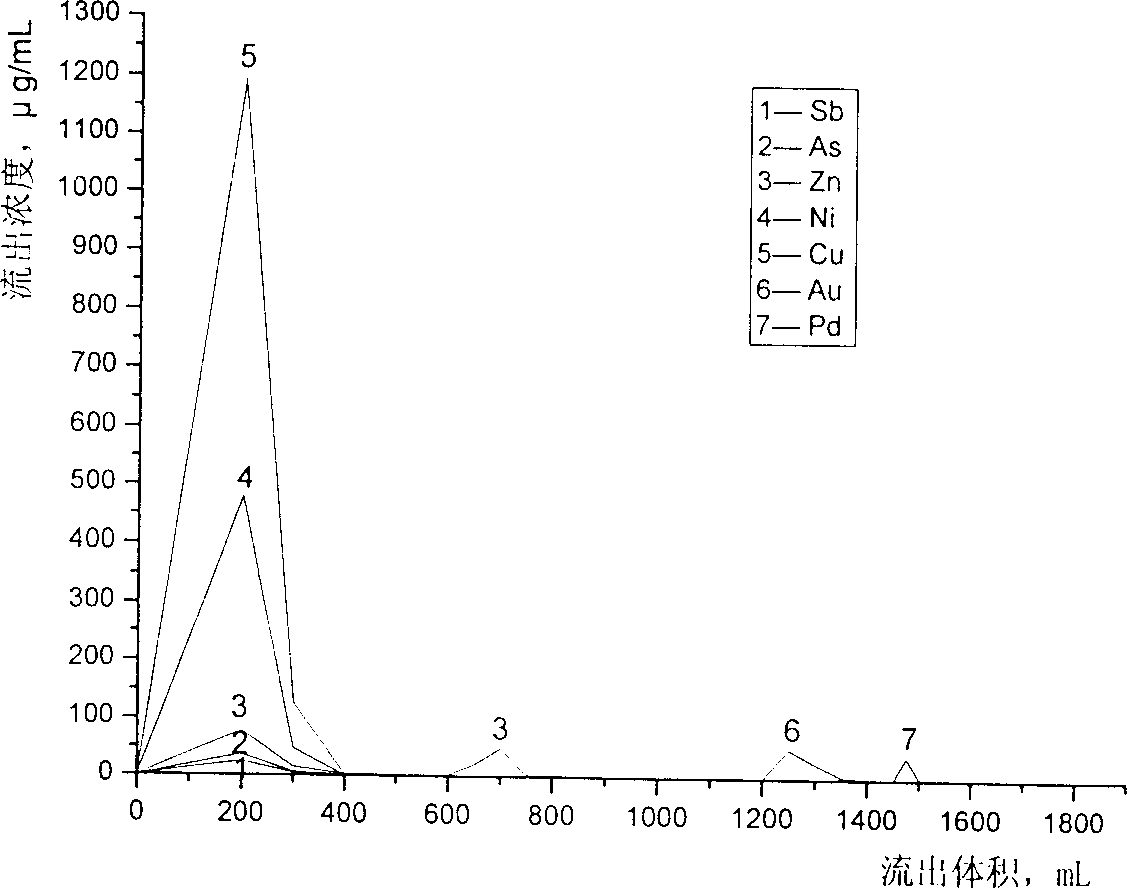

[0035] Copper Anode Slime Separation

[0036] In the test, the treatment volume of copper anode slime was 5g, the injection volume was 200mL, the total concentration of hydrochloric acid medium was 1.0mol / L, and the linear flow rate of the injection mobile phase was 5cm / min; the chromatographic column was φ11mm×125mm; the first group of eluent 400mL0.5mol / L hydrochloric acid, 50mL0.1mol / L hydrochloric acid, 50mL water, 50mL0.1mol / L hydrochloric acid, 50mL water, 300mL 0.2mol / L HCl+0.5g / L EDTA, mobile phase linear flow rate 10cm / min; The second group of eluent is 100mL1.0mol / L KSCN+20g / L ascorbic acid, the linear flow rate of the mobile phase is 4cm / min; the third group of eluent is 200mL MIBK equilibrated with hydrochloric acid, and the volume ratio of MIBK to concentrated hydrochloric acid is 7 / 1, the linear flow rate of the mobile phase is 4.5cm / min; the eluent of the fourth group is 25mL ethanol and 25mL water, and the linear flow rate of the mobile phase is 3cm / min; the el...

Embodiment 3

[0042] blister copper separation

[0043] The separation test was carried out with 5g crude copper, the injection volume was 200mL, the total concentration of hydrochloric acid medium was 2.0mol / L, the linear flow rate of the injection mobile phase was 10cm / min; the chromatographic column was φ11mm×130mm; the first group of eluent was 300mL. 2mol / L hydrochloric acid, 50mL water, 50mL0.1mol / L hydrochloric acid, 50mL water, 200mL0.12mol / L HCl+1g / L EDTA, mobile phase linear flow rate 15cm / min; the second eluent is 100mL 1.0mol / L NH 4 SCN+20g / L ascorbic acid, the linear flow rate of the mobile phase is 4cm / min; the third group of eluent is 200mL MIBK equilibrated with hydrochloric acid, the volume ratio of MIBK to concentrated hydrochloric acid is 10 / 1, and the linear flow rate of the mobile phase is 3cm / min ; The fourth group of eluent is 25mL ethanol, 25mL water, the linear flow rate of mobile phase is 6cm / min; the fifth group of eluent is 100mL0.5mol / L NH 4 Cl+1.0mol / L NH 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com