Automatic dosing method and device for hydrochloric acid regeneration desilication flocculant

A technology of automatic dosing and flocculant, applied in chlorine/hydrogen chloride purification, chlorine/hydrogen chloride and other directions, can solve the problems of insufficient dosing concentration, unstable operation of acid regeneration desilication system, etc., to achieve convenient equipment maintenance and avoid dosing Unbalanced concentration, the effect of automatic control and real-time adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

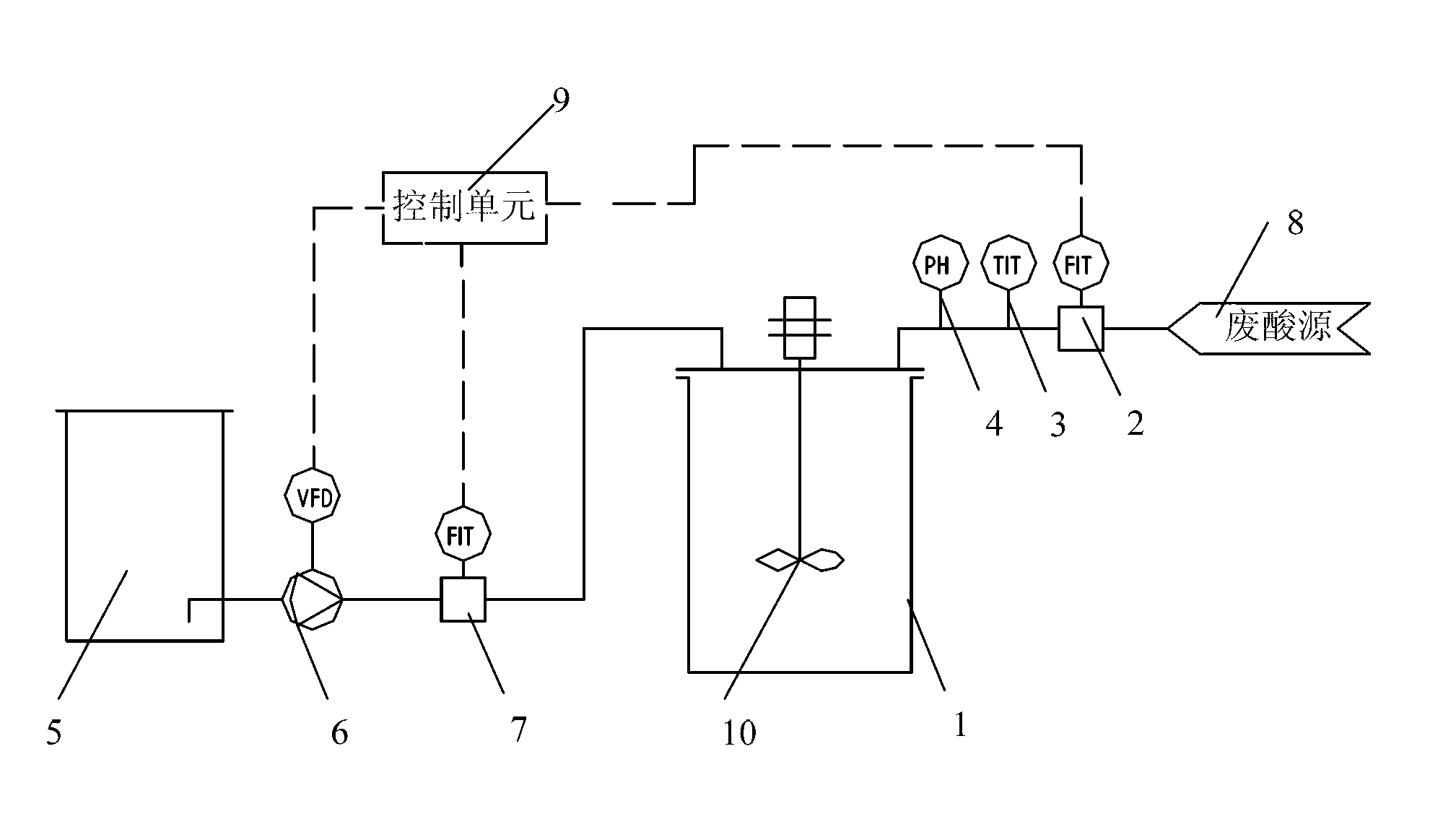

[0038] see figure 1 The hydrochloric acid regenerated desiliconization flocculant automatic dosing device provided in this embodiment is used to automatically add flocculant on demand to the flocculation tank 1 that continuously injects the neutralized waste acid, and the flocculation tank 1 is supplied by the flocculant The pipe (not shown) communicates with the flocculant storage tank 5, and the flocculant is stored in the flocculant storage tank 5, and a waste acid supply pipe is connected to the flocculation tank 1, and the waste acid supply pipe and the waste acid source 8 connections.

[0039]The automatic dosing device includes a waste acid flow meter 2, a waste acid pH meter 4, a waste acid thermometer 3, a flocculant dosing pump, a flocculant flow meter 7, a flocculant concentration meter and a control unit 9. The waste acid flow Meter 2, waste acid pH meter 4 and waste acid thermometer 3 are respectively installed on the waste acid supply pipe, the flocculant dosing...

Embodiment 2

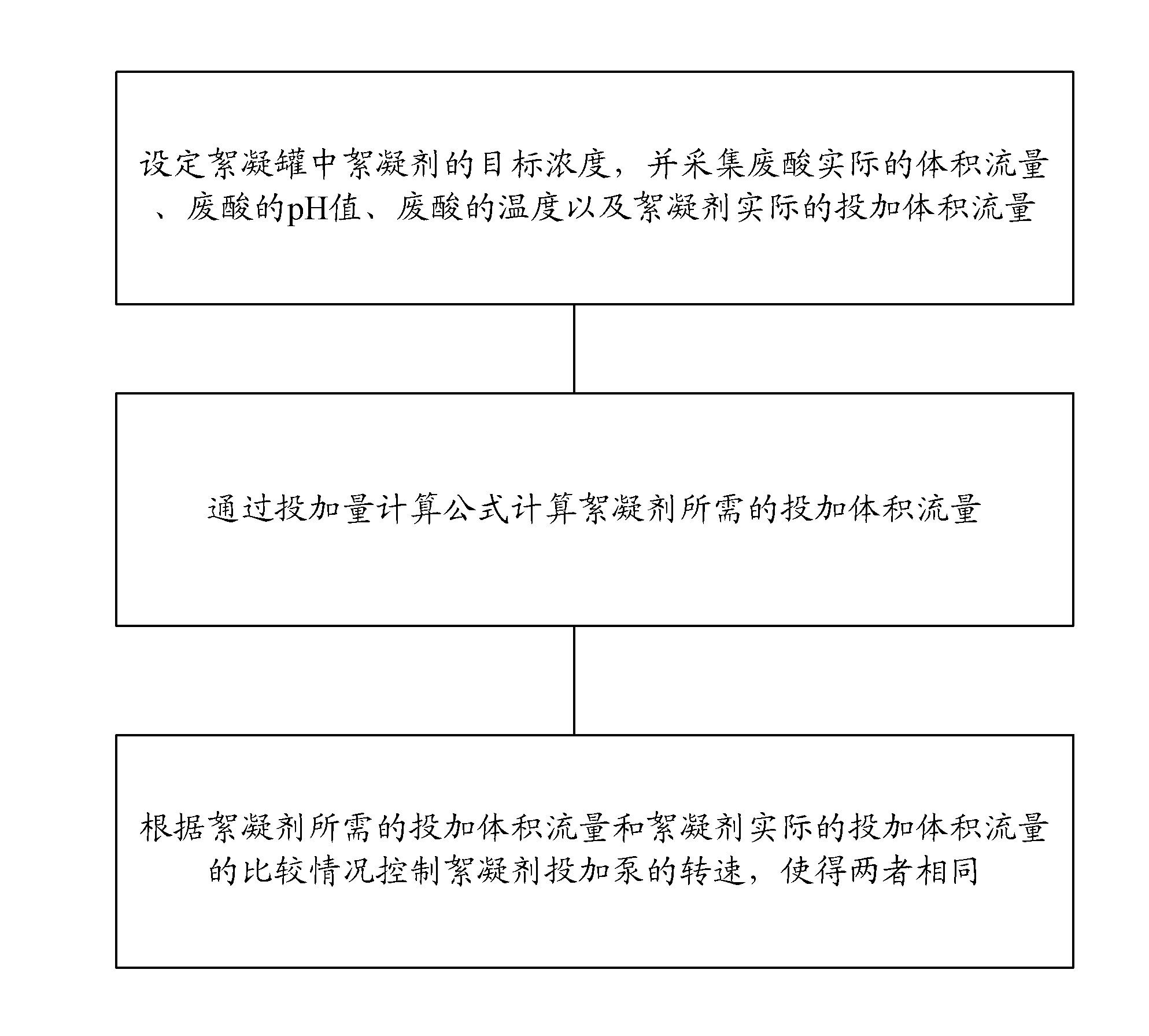

[0050] see figure 2 , this embodiment provides an automatic dosing method for hydrochloric acid regenerated desiliconization flocculant, the waste acid from the upstream process section (waste acid neutralization tank) flows into the flocculation tank 1 at the waste acid volume flow rate F2 (m3 / h), Described automatic dosing method comprises the steps:

[0051] Step 1: Set the target concentration of the flocculant in the flocculation tank 1, and collect the actual volume flow rate of the waste acid, the pH value of the waste acid, the temperature of the waste acid, and the actual volume flow rate of the flocculant.

[0052] Step 2: Calculate the volumetric flow rate required for the flocculant through the dosage calculation formula, the dosage calculation formula is F3=(N / 100)×F2×(T / 40)×[(PH / 4.2) ×1.05], where: F1—actual volume flow rate of flocculant (m 3 / h), F2—the volume flow of waste acid (m 3 / h), F3—the volume flow rate required for flocculant addition (m 3 / h), N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com