Method and apparatus for reducing electrical conductivity and total iron in cold-rolled hydrochloric acid regeneration wastewater

A technology of acid regeneration and conductivity, which is applied in the field of water treatment and can solve the problems of hydrochloric acid regeneration wastewater polluting the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

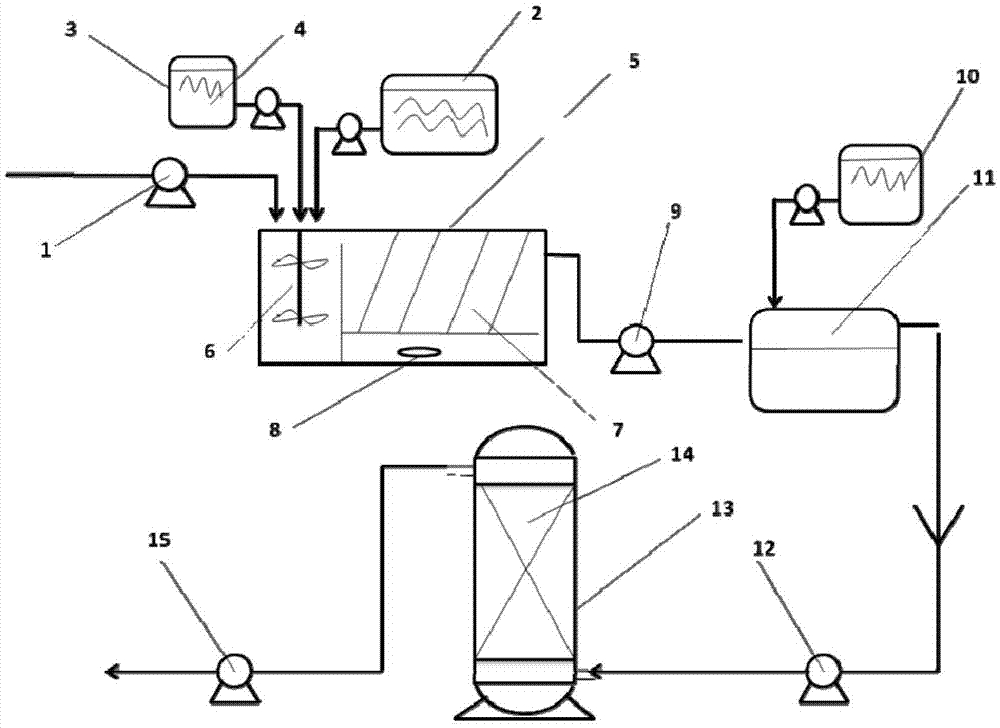

[0060] A treatment system for reducing the conductivity and total iron of cold rolling hydrochloric acid regeneration wastewater, including raw water pump 1, calcium hydroxide automatic dosing system 2, self-controlled coagulant aid dosing system 3, in-situ compound coagulant aid 4, Integrated drug dosing sedimentation tank 5, stirring and mixing area 6, inclined plate sedimentation area 7, sludge discharge pipeline and valve 8, primary lift pump 9, acid dosing system 10, PH adjustment tank 11, secondary lift pump 12, powder Coal ash adsorption tower 13, modified fly ash 14, drainage pump 15.

[0061] The water quality characteristics of the cold rolling hydrochloric acid regeneration wastewater: pH is 1.2, electrical conductivity is 28000us / cm, total iron is 520mg / L.

[0062] The cold-rolled hydrochloric acid regenerated wastewater enters the integrated dosing sedimentation tank through the raw water pump. The front of the integrated dosing sedimentation tank is a stirring an...

Embodiment 2

[0074] A treatment system for reducing the conductivity and total iron of cold rolling hydrochloric acid regeneration wastewater, raw water pump, automatic lye dosing system, self-controlled coagulant aid dosing system, in-situ compound coagulant aid, integrated dosing sedimentation tank , Stirring mixing area, inclined plate sedimentation area, mud discharge pipes and valves, primary lift pump, acid dosing system, PH adjustment tank, secondary lift pump, fly ash adsorption tower, modified fly ash, drainage pump.

[0075] The water quality characteristics of the cold rolling hydrochloric acid regeneration wastewater: pH is 1.9, electrical conductivity is 22000us / cm, total iron is 313mg / L.

[0076] The cold-rolled hydrochloric acid regenerated wastewater enters the integrated dosing sedimentation tank through the raw water pump. The front of the integrated dosing sedimentation tank is a stirring and mixing area, the rear is an inclined plate sedimentation area, and the bottom is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com