Pickling acid regeneration control method

A control method and acid regeneration technology, applied in the field of steel rolling, can solve the problems of reducing operating costs, disadvantage, and inability to achieve efficient utilization of waste acid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

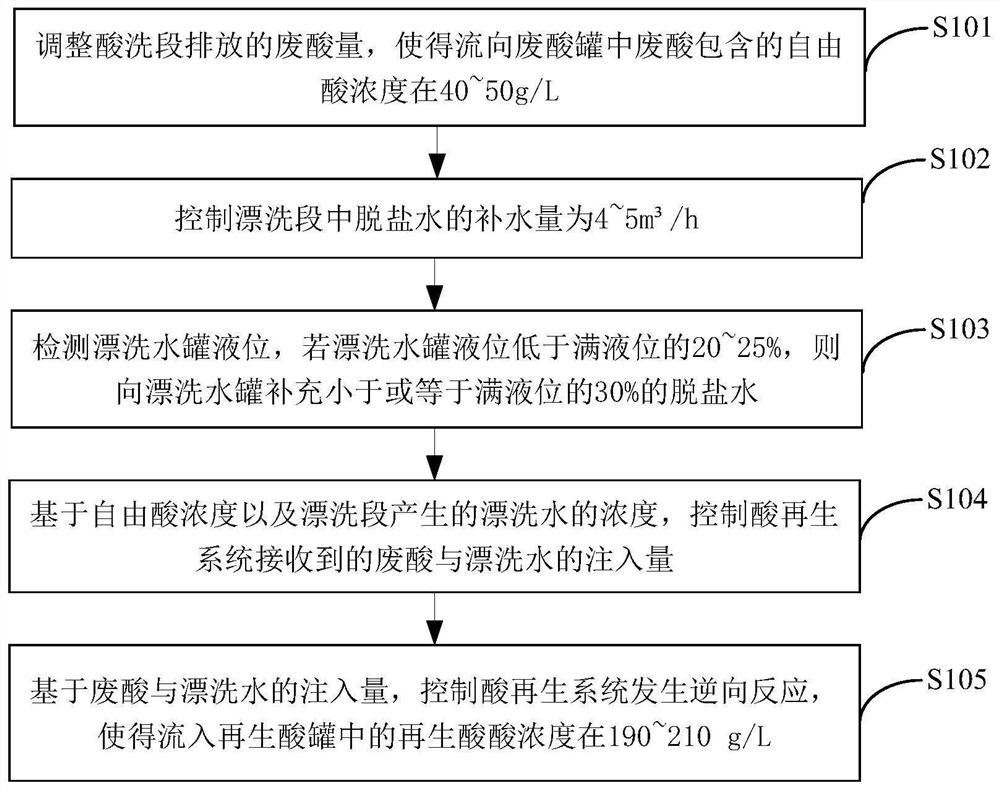

[0021] The embodiment of the present application provides a pickling acid regeneration control method, which can reasonably control the free acid concentration of waste acid discharged from the pickling section without affecting the pickling quality, reduce the amount of rinse water, and reduce the start and stop of acid regeneration times, in order to comprehensively reduce the operating cost of pickling and acid regeneration.

[0022] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

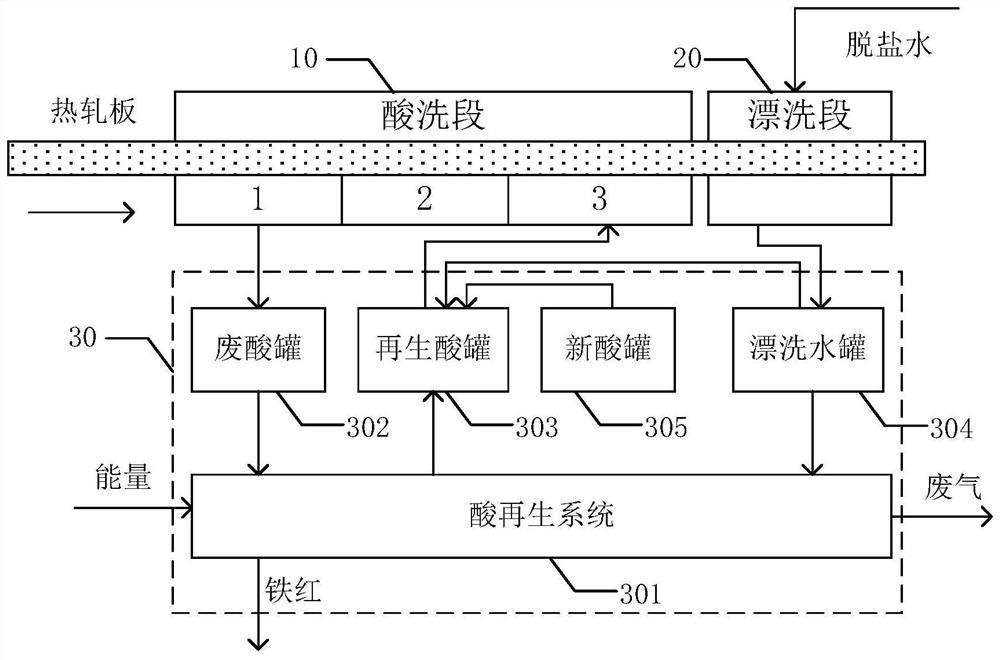

[0023] The pickling acid regeneration control method provided by this application can be applied to cold rolling systems, such as figure 1 As shown, the cold rolling system includes a pickling section 10 , a rinsing section 20 and a hydrochloric acid regeneration treatment section 30 , and the hydrochloric acid regenerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com