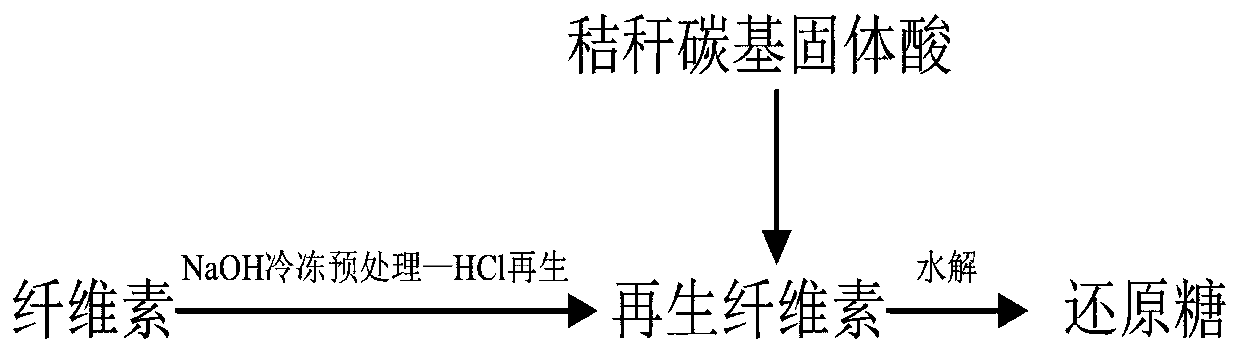

Method for hydrolyzing cellulose through cooperation between freezing pretreatment and straw carbon-based solid acid

A carbon-based solid acid, freezing pretreatment technology, applied in chemical instruments and methods, sugar production, chemical/physical processes, etc. The effect of low energy consumption and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for freezing pretreatment in conjunction with straw carbon-based solid acid hydrolysis of cellulose, the steps are as follows:

[0035] Step 1. Freezing pretreatment and regeneration:

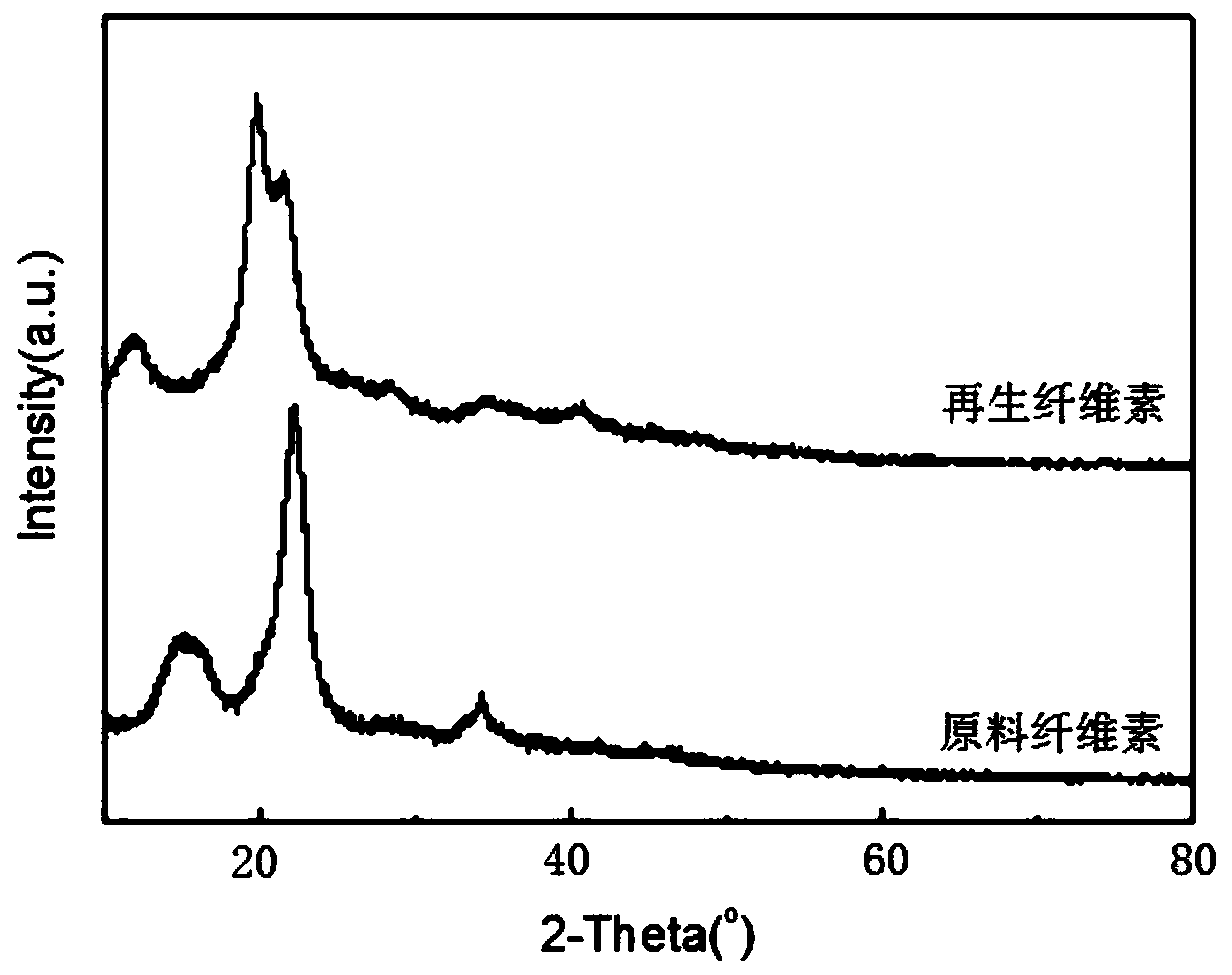

[0036] Mix the cellulose and sodium hydroxide solution evenly according to a certain mass-volume ratio, place it in the environment of -18 ~ -30 ℃ and freeze it for 24 hours, then take it out and thaw it naturally at room temperature, and stir;

[0037] Prepare a hydrochloric acid solution equal to the molar volume of the sodium hydroxide solution, mix the obtained thawed solution with the hydrochloric acid solution, make the mixed solution neutral, and generate white flocs in the mixed solution, which is regenerated cellulose;

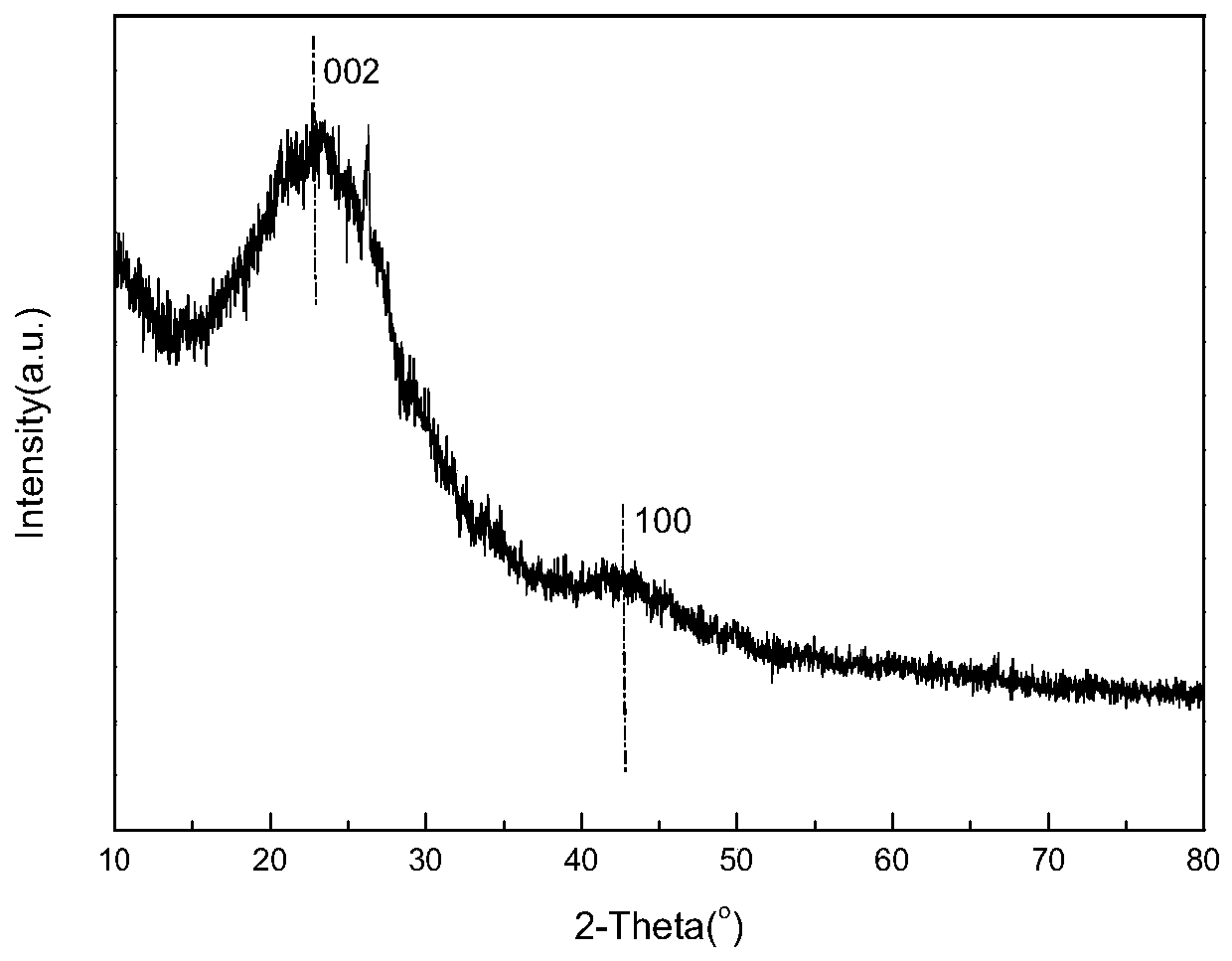

[0038] Step 2, preparing straw carbon-based solid acid:

[0039] The straw is dried, pulverized, and sieved to obtain straw powder, and the straw powder is carbonized under the protection of nitrogen to obtain a black powder, and the black powder is gr...

Embodiment 2

[0043] A method for freezing pretreatment in conjunction with straw carbon-based solid acid hydrolysis of cellulose, the steps are as follows:

[0044] Step 1. Freezing pretreatment and regeneration:

[0045] According to the mass volume ratio of 0.01~0.08g: 1mL, mix the cellulose with the sodium hydroxide solution with a mass concentration of 1~9% evenly, place it in the environment of -18~-30℃ and freeze it for 24 hours, then take it out to the room temperature environment thaw, stir;

[0046] Prepare a hydrochloric acid solution equal to the molar volume of the sodium hydroxide solution, mix the obtained thawed solution with the hydrochloric acid solution, and stir rapidly to make the mixed solution neutral, and white flocs are formed in the mixed solution, which is regenerated cellulose ;

[0047] Step 2, preparing straw carbon-based solid acid:

[0048] The straw is dried, pulverized, and sieved to obtain straw powder, and the straw powder is carbonized under the prote...

Embodiment 3

[0052] A method for freezing pretreatment in conjunction with straw carbon-based solid acid hydrolysis of cellulose, the steps are as follows:

[0053] Step 1. Freezing pretreatment and regeneration:

[0054] According to the mass volume ratio of 0.01~0.08g: 1mL, mix the cellulose with the sodium hydroxide solution with a mass concentration of 1~9% evenly, place it in the environment of -18~-30℃ and freeze it for 24 hours, then take it out to the room temperature environment thaw, stir;

[0055] Prepare a hydrochloric acid solution equal to the molar volume of the sodium hydroxide solution, mix the obtained thawed solution with the hydrochloric acid solution, and stir rapidly to make the mixed solution neutral, and white flocs are formed in the mixed solution, which is regenerated cellulose ;

[0056] Step 2, preparing straw carbon-based solid acid:

[0057] The crop straw is dried, crushed, and passed through a 100-mesh sieve to obtain straw powder. The straw powder is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com