Technology and system for treating hydrochloric acid regeneration device tail gas

A regeneration device and exhaust gas treatment technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high residents' opinions, environmental hazards, equipment and building corrosion, etc., and achieve quick results, reduce load, and invest. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

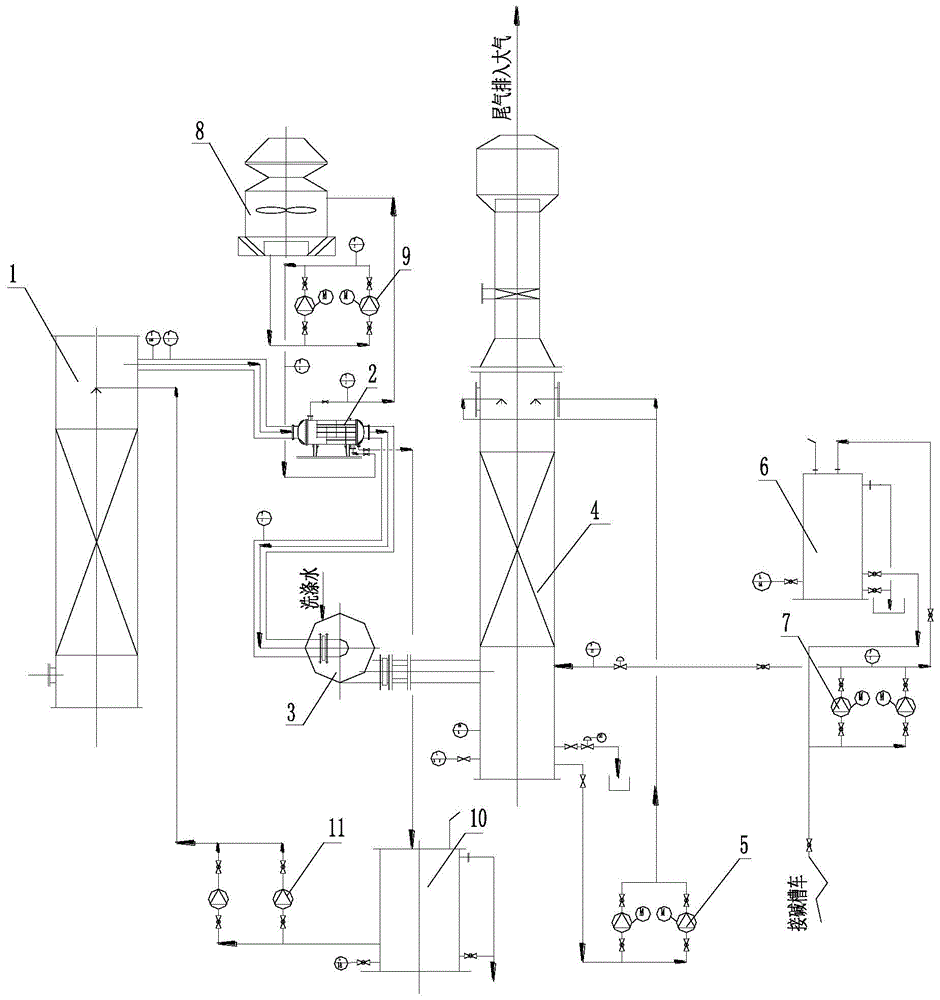

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0023] See figure 1 , is a process flow diagram of the present invention, a kind of hydrochloric acid regeneration device tail gas treatment process of the present invention, comprises the steps:

[0024] 1) The tail gas from the hydrochloric acid regeneration unit coming out of the absorption tower 1 enters the condenser 2 to exchange heat indirectly with the cooling water, condenses the tail gas above 90°C to below 40°C, and the condensate after part of the water vapor in the tail gas condenses enters the collection water Tank 10 is used as the spray liquid of absorption tower 1;

[0025] 2) The cooling water inlet temperature is 30-32°C, after heat exchange, the temperature rises to 35-37°C, then goes to the cooling tower 1, re-cools to 30-32°C, and then returns to the condenser 2 for recycling, during which the evaporated water is regularly r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com