A kind of wet blue leather processing wastewater treatment process

A treatment process and wastewater processing technology, which is applied in animal processing wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of reduced biochemical system treatment effect, limited removal capacity, biochemical system damage, etc., to improve pollution , Reduce environmental burden, low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

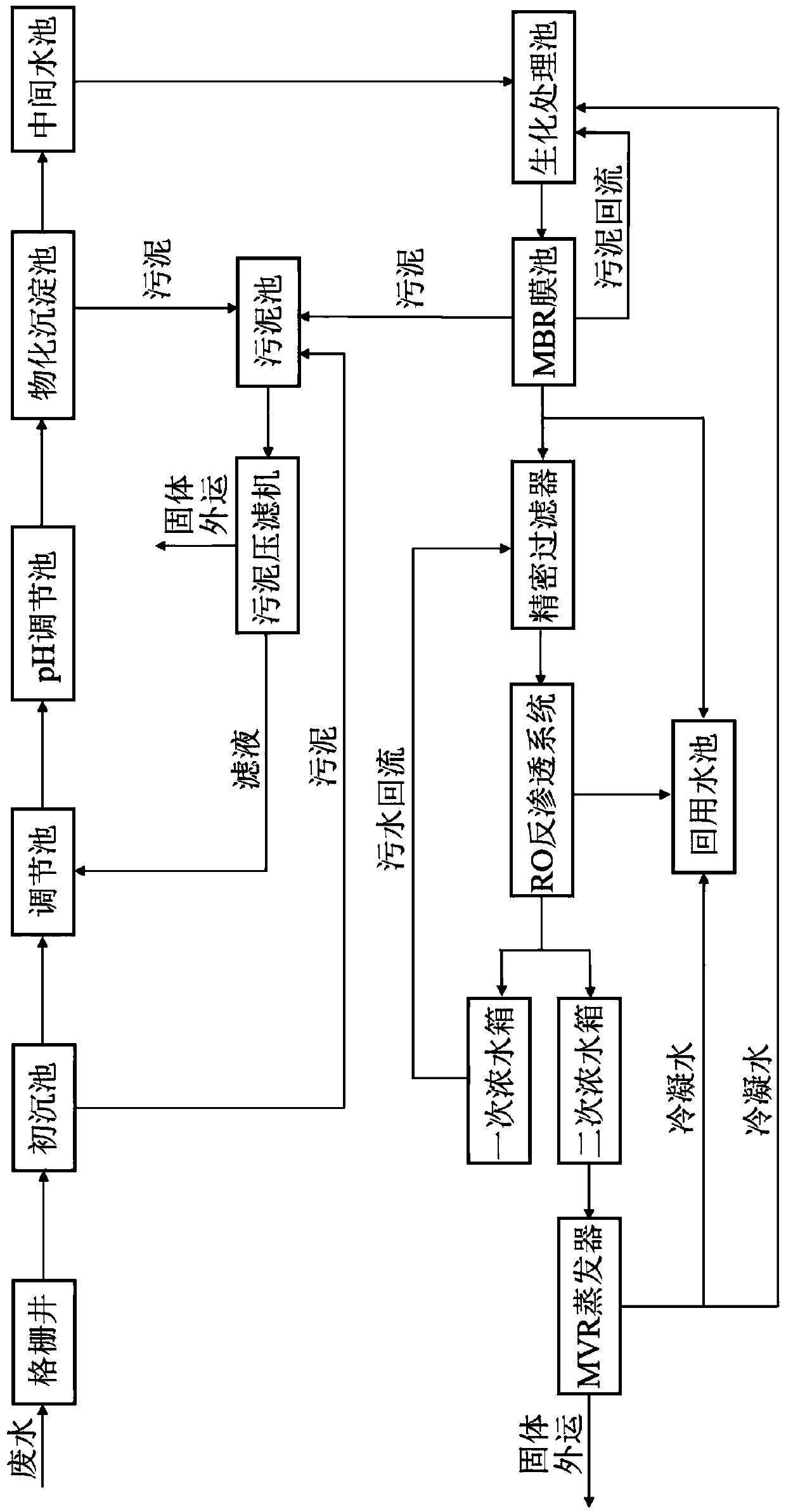

[0057] Wet blue leather processing wastewater from Jindun Zhuoye Leather Technology Co., Ltd., Gaozhou City, Guangdong Province was selected. figure 1 The process flow shown is 150 days of operation treatment, and the water quality parameters of the influent and effluent (water in the reuse pool) of sewage treatment are shown in Table 1.

[0058] Table 1 Influent and effluent water quality parameters of sewage treatment

[0059] Project indicators

[0060] It can be known from Table 1 that the process of the present invention is used for the treatment and reuse of wet blue leather processing wastewater, and the operation effect is stable. 5 The removal rate of ammonia nitrogen is more than 98%, the removal rate of ammonia nitrogen is more than 98%, the electrical conductivity is reduced by more than 80%, the removal rate of salt is more than 80%, and the effluent water quality can stably meet the "Industrial Water Standard" (GBT19923-2005) for reclaimed water. As th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com