Novel concentrated hydrochloric acid recovering mechanism for hydrochloric acid regeneration

A recovery mechanism, a technology for hydrochloric acid, applied in chlorine/hydrogen chloride purification, chlorine/hydrogen chloride and other directions, can solve the problems of affecting the ecological environment, affecting the environment, and not being able to recover waste hydrochloric acid, etc., to improve purity, improve production efficiency, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

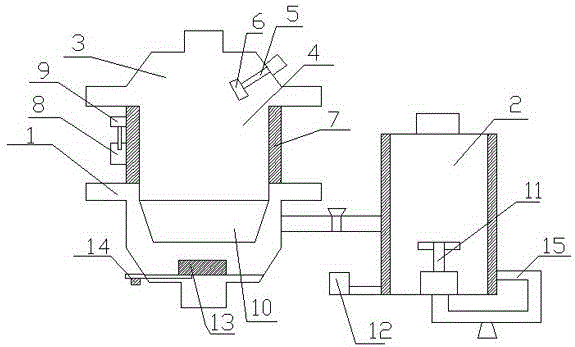

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] A new concentrated hydrochloric acid recovery mechanism for hydrochloric acid regeneration, which is provided with a concentration device 1 and a pre-concentration tank 2, the concentration device 1 and the pre-concentration tank 2 are connected to each other, the concentration device 1 is provided with a cover 3, and the cover 3 is provided with a storage Liquid tank 4, the bottom of the liquid storage tank 4 is provided with a bottom cover, the liquid storage tank 4 is provided with a hydrochloric acid inlet, the hydrochloric acid inlet is provided with a conduit 5, a nozzle 6 is provided under the conduit 5, and an atomizer is provided on the nozzle 6 to atomize The device is located inside the nozzle 6, and the liquid storage tank 4 is provided with an anti-corrosion layer 7, the anti-corrosion layer 7 is composed of a ceramic layer and a filling layer, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com